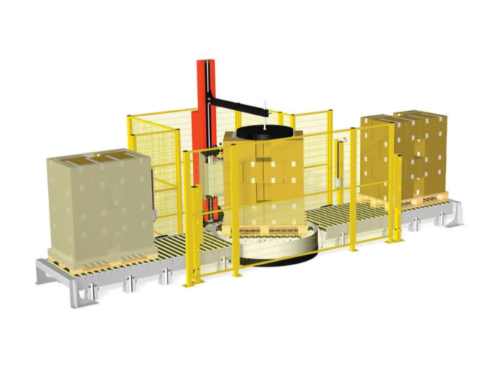

SOCO PRS Single palletising robot – automatic palletising

Compact, flexible and efficient standard palletising robot.

Compact, flexible and efficient standard palletising robot.

- Can be configured and equipped with many different features to meet specific needs and applications.

- User friendly software makes it easy and swift to shift to or build new optimised pallet patterns.

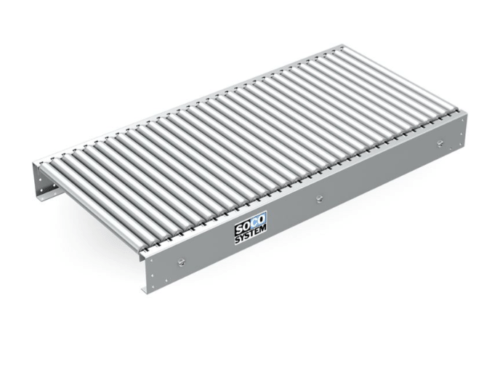

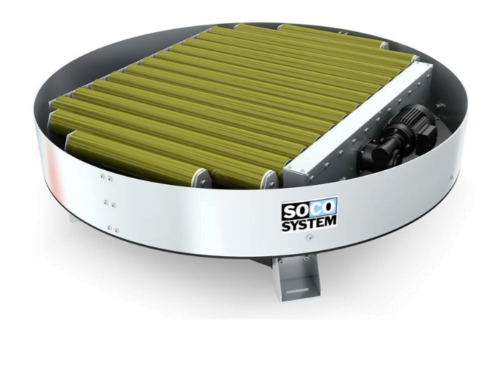

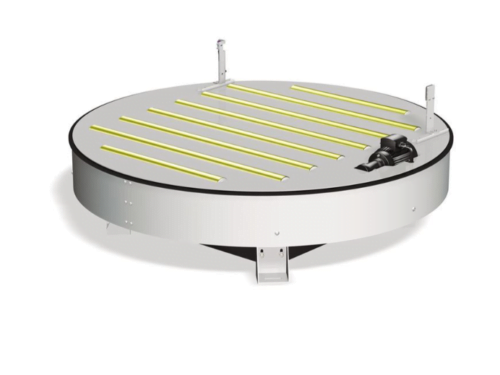

- Can be combined with the extensive SOCO SYSTEM product range of pallet handling equipment.

- The robot comes tested with customer cases and pallet patterns.

New pallet pattern in 30 seconds

If the pallet pattern is already in the IPC, it takes less than 30 seconds to switch to another programme.

A new pallet pattern can easily be generated by the PalletBuilder in the SOCOLogic software in the robot IPC. Pallet patterns can also be generated using external optimisation software, such as CAPE PACK®, and can be transferred online or via USB.

Safe to operate, simple and versatile

The machine requires minimal maintenance and is easy to access.

It is equipped with safety fencing that meets CE requirements.

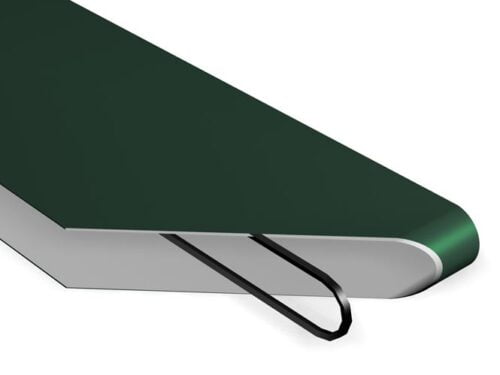

Greater pallet capacity – Improved freight economy

All types of cases, even heavy and bulky ones, can be stacked at heights up to 2700 mm in order to fully utilise the capacity of lorries and containers.

Stainless steel for wet environments

The robot can be supplied entirely or partially in stainless steel.

The robot has powder coated finish in RAL 2002 and RAL 9005 colours as standard. Special colours are available for at a surcharge.

Layer pad magazine

PRS single robot can be extended with magazine for intermediate sheets.