SOCO Rotary tables

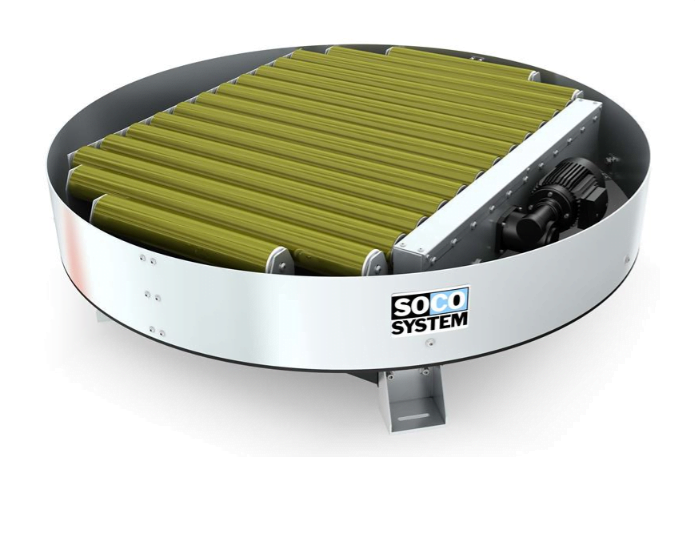

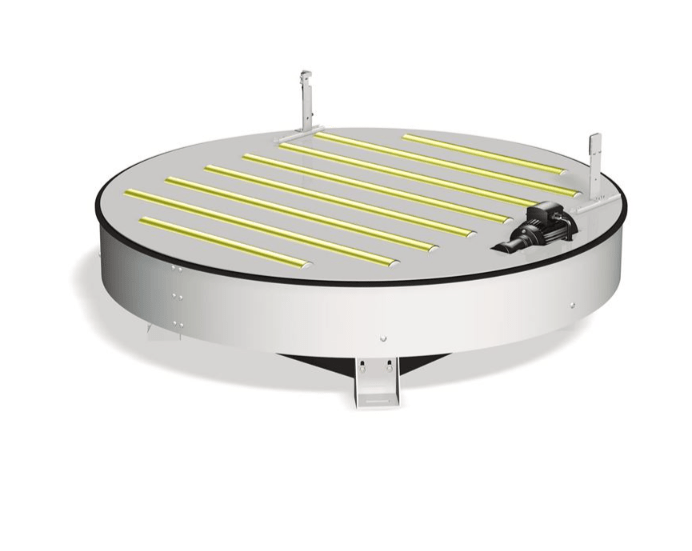

The rotary table is used to change the direction of pallet travel. Fitted with pallet roller conveyor – also available with chain conveyor upon request.

The rotary table is used to change the direction of pallet travel. Fitted with pallet roller conveyor – also available with chain conveyor upon request.

The turntable can rotate ± 90° and ± 180°. Rotation: 2.8 or 3.75 RPM.

SOCO Rotary tables

Overview

SOCO Rotary Tables are designed to facilitate efficient and flexible handling of products and pallets in industrial settings. These rotary tables are particularly useful for packaging stations and pallet handling, providing a simple and cost-effective solution for product accumulation and direction change.

Key Features

Packaging Station Rotary Tables

- Product Accumulation: Ideal for accumulating retail products, allowing operators to perform other tasks simultaneously.

- Ease of Access: Products are kept within easy reach as they rotate on the table.

- Adjustable Height: Legs are height adjustable to ensure ergonomic working conditions.

- Speed Options: Standard speed is 6.00 rotations per minute, with optional speeds of 3.77, 2.81, and 2.20 rotations per minute. Adjustable speed control is also available.

- Construction: Available in three versions:

- Model A: Plastic laminated tabletop.

- Model B: Solid plastic tabletop.

- Model C: 18/8 stainless steel with a solid plastic tabletop.

- Braked Castors: Equipped with sturdy castors with efficient brakes that lock in both travel and rotation directions.

Pallet Rotary Tables

- Direction Change: Designed to change the direction of pallet travel, typically by 90°.

- Rotation Range: Can rotate from 0 to 270°.

- Integration: Fitted with pallet roller conveyors, with the option for chain conveyors upon request.

Technical Specifications

Packaging Station Rotary Tables

- Diameter: Ø 1200 mm

- Height: Minimum 715 mm

- Speed:

- Standard: 6.00 rotations per minute

- Optional: 3.77, 2.81, 2.20 rotations per minute

- Models and Item Numbers:

- Model A:

- 6.00 rot/min: 450906003

- 3.77 rot/min: 450903703

- 2.81 rot/min: 450902803

- 2.20 rot/min: 450902203

- Model B:

- 6.00 rot/min: 450906023

- 3.77 rot/min: 450903723

- 2.81 rot/min: 450902823

- 2.20 rot/min: 450902223

- Model C:

- 6.00 rot/min: 850906003

- 3.77 rot/min: 850903703

- 2.81 rot/min: 850902803

- 2.20 rot/min: 850902203

- Model A:

Pallet Rotary Tables

- Rotation: 0 to 270° (standard 90°)

- Integration: Fitted with pallet roller conveyors, chain conveyors available upon request

Benefits

- Efficiency: Streamlines the handling and accumulation of products and pallets.

- Flexibility: Multiple speed options and adjustable height ensure adaptability to various operational needs.

- Safety: Braked castors and sturdy construction provide stability and safety during operation.

- Ease of Use: Simple integration into existing systems and user-friendly operation.

Applications

SOCO Rotary Tables are ideal for:

- Packaging Stations: Accumulating and managing retail products efficiently.

- Warehouses: Changing the direction of pallet travel to optimise space and workflow.

- Manufacturing Plants: Streamlining the movement of products and pallets in production lines.

- Distribution Centres: Enhancing the flow of goods for shipping and receiving operations.

Conclusion

SOCO Rotary Tables offer a practical and efficient solution for enhancing the functionality of packaging stations and pallet handling systems. Their robust design, versatile speed options, and ease of integration make them an excellent choice for various industrial applications. Whether you need to accumulate products or change the direction of pallet travel, SOCO Rotary Tables provide reliable and efficient performance.

For more detailed information and to explore how SOCO Rotary Tables can benefit your operations, please contact us.

Datasheet

Specifications | |

|---|---|

Payload | Max. 900 kg. depending on conveyor width. |

Standard height | 350 mm or 470 mm. Minimum height 310 mm. |

Gear motor | 0.25 kW. |

Subject to alteration. | |