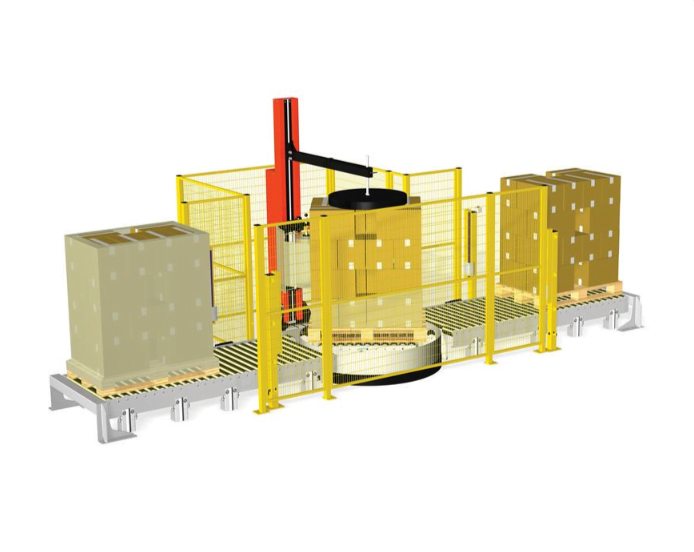

SOCO PW-1200 Fully-automatic pallet stretch-wrapper

PW-1200 is well suited for integration into fully automatic packaging lines. PW-1200 applies, cuts, and brushes on the film.

PW-1200 is well suited for integration into fully automatic packaging lines. PW-1200 applies, cuts, and brushes on the film.

The standard equipment includes, among other things:

- Frequency control system which makes it possible to adjust the machine to different types of pallet loads. This offers a great advantage where pallet loads are light or perhaps fragile. The machine starts up slowly and then accelerates. Independent setting of film carriage and turntable speed.

- Signal communication for control of pallet transport to and from the turntable.

- Adjustable automatic top pressure plate. The top pressure plate can be adjusted to the current maximum load height. This ensures minimal travel of the top pressure plate and increased machine capacity.

- Driven pallet roller conveyor on turntable.

- Film alarm that automatically stops the machine and sends a signal when the film has run out or not been applied.

- Brake motor which stops the turntable in the required position.

- Pre-stretch fully utilises the film. Pre-stretch is 2:1.

Control system and operation

The PW-1200 is equipped with a unique and user-friendly control system ensuring high productivity at lowest possible costs.

The machine is easy to operate and to set to achieve optimum pallet load wrapping:

- Variable number of wraps at top and bottom upon selection (1-9).

- Independent setting of turntable and up/down movement speed of film carriage during operation.

- Current number of completed wraps is displayed on the control panel.

- Different types of control systems are available.

Overview

The SOCO PW-1200 is a fully-automatic pallet stretch-wrapper designed for high-volume packaging operations. This advanced machine is ideal for integration into fully automatic packaging lines, offering efficient and consistent wrapping of palletised loads.

Key Features

- Fully Automatic Operation: Designed for seamless integration into automatic production lines.

- Variable Wrapping Programs: Allows for independent setting of turntable and up/down carriage speeds.

- Adjustable Wrap Count: Variable number of wraps at top and bottom upon selection (1-9).

- User-Friendly Control System: Ensures high productivity at lowest possible costs.

- Film Tension Control: Electronically controlled film tension for optimal load stability.

- Top Sheet Dispenser: Optional feature for additional protection.

Technical Specifications

- Pallet Load Size:

- Maximum Height: 2400 mm (standard), 3000 mm (optional)

- Maximum Weight: 2000 kg

- Turntable Diameter: 1650 mm (standard), 1800 mm (optional)

- Wrapping Speed: Up to 20 pallets/hour

- Power Supply: 3 x 400V, 50 Hz

- Air Supply: 6 bar, 50 l/min

Benefits

- Efficiency: High-speed operation capable of wrapping up to 20 pallets per hour.

- Consistency: Automated operation ensures uniform wrapping quality for all pallets.

- Flexibility: Adaptable to various pallet sizes and wrapping requirements.

- Cost-Effective: Optimised film usage and high productivity reduce operational costs.

- Easy Integration: Well-suited for incorporation into existing packaging lines.

Applications

The SOCO PW-1200 is perfect for:

- Large Warehouses: Handling high-volume pallet wrapping needs.

- Manufacturing Plants: Integrating into end-of-line packaging processes.

- Distribution Centers: Ensuring secure and efficient packaging for shipping.

- Food and Beverage Industry: Providing consistent protection for palletised products.

Conclusion

The SOCO PW-1200 Fully-automatic pallet stretch-wrapper offers a robust and efficient solution for high-volume pallet wrapping needs. Its advanced features, customisable settings, and easy integration capabilities make it an excellent choice for businesses looking to automate and optimise their packaging processes.

For more detailed information and to explore how the SOCO PW-1200 can benefit your operations, please contact us.

Datasheet

Specifications | PW-1200 (0812) | PW-1200 (1012) |

|---|---|---|

Pallet load dimensions | ||

Max. length (mm) | 1200 | 1200 |

Max. width (mm) | 800 | 1000 |

Max. height (mm) | 2030 | 2030 |

Min. height (mm) | 345 | 345 |

Max. pallet load (kg) | 1500 | 1500 |

Machine dimensions | ||

Length (mm) | 2615 | 2655 |

Width (mm) | 1480 | 1630 |

Height (mm) | 3350 | 3350 |

Min. height above floor (mm) | 350 | 350 |

Film roll dimension (mm) | Length max. 440-520, outer diameter max. 400, inner diameter 76. | |

Capacity | Max. 35 pallets per hour. | |

Electric specifications | 3 x 400 V 50 Hz, power consumption 1.0 kW, control voltage 24 V. | |

Surface treatment | All parts are powder coated or electro-galvanised. | |

Colours | Red RAL 2002, black RAL 9005 (available in other colours against an additional price). | |

Air | 11,5 l at 6 bar per cycle. | |

Subject to alteration. | ||

Ask for a configured solution, or see our standard project layouts.