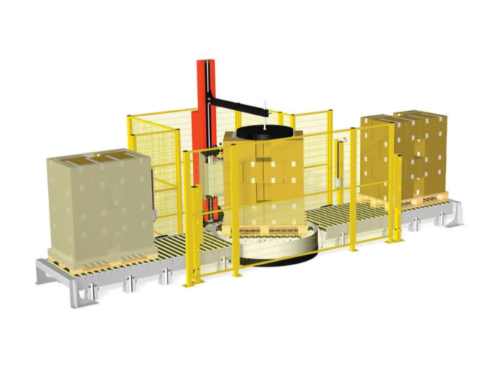

SOCO PW-1000 Semi-automatic pallet stretch-wrapper

For film with or without pre-stretch. Simple and efficient machine for the everyday job. The compact size facilitates location and relocation. The PW-1000 is available for different-sized pallet loads (see table).

For film with or without pre-stretch. Simple and efficient machine for the everyday job. The compact size facilitates location and relocation. The PW-1000 is available for different-sized pallet loads (see table).

Safety

The sealed tower, the emergency stop as well as the safety switch built into the foot plate under the film carriage make the PW-1000 a very safe machine.

The standard equipment includes, among other things:

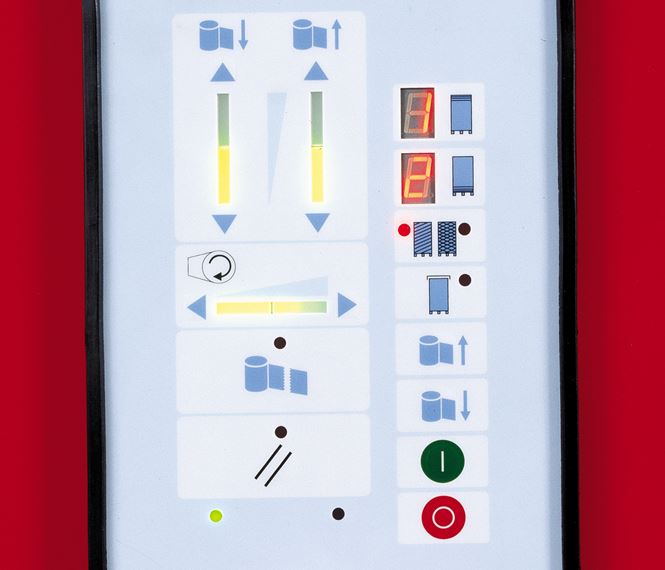

- Independent setting of film carriage and turntable speed, which makes it possible to fully utilize the film and to determine the extent of film overlap.

- Soft start on turntable. A great advantage where pallet loads are light or fragile. The turntable starts up slowly and then accelerates until the required speed has been reached.

- Memory stores the last used settings for the turntable and film carriage speeds.

- Program for rainproof pallet stretch-wrapping, offering efficient protection against rain and humidity (requires separate top film application).

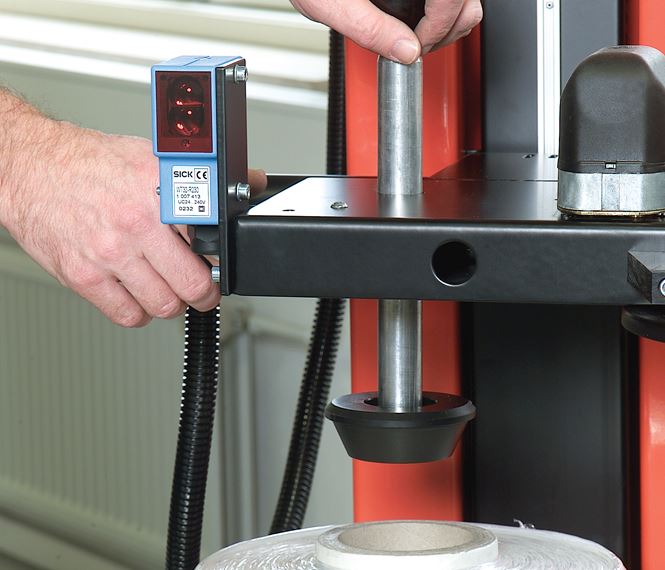

- Automatic setting of pallet load height, a photocell registers the height of the pallet load.

- Variable number of wraps at top and bottom available upon selection (1-9).

- Independent setting of turntable and up/down speed of film carriage during operation as required.

- The option of manual operation and, with this, the possibility of choosing, for instance only top wrapping.

SOCO PW-1000 Semi-automatic pallet stretch-wrapper

Overview

The SOCO PW-1000 Semi-Automatic Pallet Stretch-Wrapper is designed to provide efficient and secure wrapping of pallet loads. This versatile machine is suitable for a wide range of pallet sizes and is ideal for various industrial and commercial applications. The semi-automatic operation ensures ease of use while maintaining high productivity.

Key Features

- User-Friendly Control Panel: Easy to operate with touch membrane controls, allowing for quick setup and adjustments.

- Variable Wrapping Programs: Offers independent setting of turntable and up/down carriage speeds, as well as variable number of wraps at the top and bottom (1-9).

- Automatic Load Height Detection: A photocell registers the height of the pallet load, ensuring accurate wrapping.

- Safety Features: Includes a sealed tower, emergency stop, and a safety switch built into the foot plate under the film carriage.

- Soft Start Turntable: Gradual acceleration for handling light or fragile loads.

- Memory Function: Stores the last used settings for turntable and film carriage speeds.

- Optional Features: Includes options such as brake motor on turntable, variable film pre-stretch, electric film cutting, electric film brake, and more.

Technical Specifications

- Wrapping Height: Up to 2860 mm (varies by model)

- Turntable Diameter: Standard sizes available to accommodate various pallet dimensions

- Maximum Pallet Weight: 2000 kg

- Power Supply: 3×230/400 V 50 Hz

- Power Consumption: 0.5 kW

- Wrapping Speed: Up to 50 pallets per hour

Benefits

- Efficiency: Semi-automatic operation streamlines the wrapping process, reducing manual labor and increasing productivity.

- Flexibility: Multiple wrapping programs and adjustable settings provide versatility to meet different packaging requirements.

- Stability: Automatic load height detection and soft start turntable ensure stable and secure wrapping.

- Ease of Use: User-friendly controls and minimal setup make the machine easy to operate, even for inexperienced users.

- Durability: Constructed from high-quality materials, the PW-1000 is designed for long-term reliability in demanding environments.

Applications

The SOCO PW-1000 Semi-Automatic Pallet Stretch-Wrapper is perfect for:

- Warehouses: Efficiently wrapping pallet loads for storage and shipping.

- Manufacturing Plants: Securing products on pallets for transportation.

- Distribution Centers: Ensuring that palletized goods are securely wrapped for delivery.

- Food and Beverage Industry: Providing consistent and reliable wrapping for palletized products.

Conclusion

The SOCO PW-1000 Semi-Automatic Pallet Stretch-Wrapper offers a practical and efficient solution for wrapping pallet loads in various industrial and commercial settings. Its versatile load handling, multiple wrapping programs, and advanced safety features make it an excellent choice for businesses looking to enhance their packaging operations. Whether you’re managing a warehouse, manufacturing plant, or distribution center, the PW-1000 ensures secure and efficient pallet wrapping.

For more detailed information and to explore how the SOCO PW-1000 can benefit your operations, please contact us.

Datasheet

Specifications | PW-1000 (621) | PW-1000 (631) | PW-1000 (121) | PW-1000 (131) |

|---|---|---|---|---|

Pallet load dimensions | ||||

Max. length (mm) | 1200 | 1200 | 1200 | 1200 |

Max. width (mm) | 800 | 800 | 1000 | 1000 |

Max. height (mm) | 2360 | 2860 | 2360 | 2860 |

Max. pallet load (kg) | 1500 | 1500 | 1000 | 1000 |

Machine dimensions | ||||

Length (mm) | 2615 | 2615 | 2680 | 2680 |

Width (mm) | 1480 | 1480 | 1630* | 1630* |

Height (mm) | 2600 | 3100 | 2600 | 3100 |

Min. height above floor (mm) | 75 | 75 | 75 | 75 |

Film roll dimension (mm) | Length max. 440-520, outer diameter max. 400, inner diameter 76. | |||

Capacity | Max. 50 pallets per hour. | |||

Electric specifications | 3 x 230/400 V, 50 Hz, power consumption 0.5 kW. Other specifications upon request. | |||

Surface treatment | All parts are powder-coated or electro-galvanised. | |||

Colours | Red RAL 2002, black RAL 9005 (available in other colours at a surcharge). | |||

*Safety cover required. Subject to alteration. | ||||