SOCO Transfer units

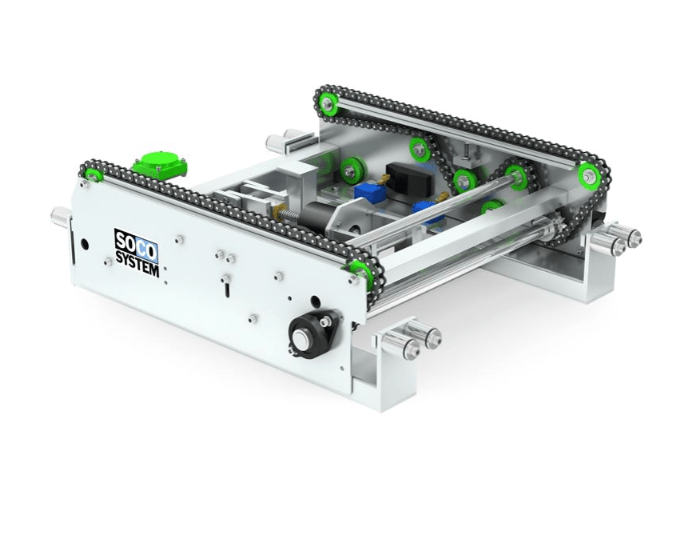

The transfer unit changes the pallet direction travel by 90°. The 90° transfer unit is a chain conveyor which is raised and lowered automatically above and below roller height.

The transfer unit changes the pallet direction travel by 90°. The 90° transfer unit is a chain conveyor which is raised and lowered automatically above and below roller height.

Can be fitted in all pallet roller conveyors where the height exceeds 350 mm.

Motors:

Two motors – one for up/down movement and one for chain movement.

SOCO Transfer units

Overview

SOCO Transfer Units are designed to facilitate the efficient and automated transfer of pallets between different conveyor lines. These units are particularly useful for changing the direction of pallet travel by 90°, making them an essential component in complex material handling systems.

Key Features

- 90° Transfer Capability: Changes the direction of pallet travel by 90°, optimising the flow of materials in a production or warehouse setting.

- Automatic Operation: The chain conveyor is raised and lowered automatically above and below roller height, ensuring seamless integration with existing conveyor systems.

- Dual Motors: Equipped with two motors—one for the up/down movement and one for the chain movement—providing reliable and efficient operation.

- High Payload Capacity: Capable of handling pallets with a maximum weight of 1500 kg, making it suitable for heavy-duty applications.

- Versatile Integration: Can be fitted in all pallet roller conveyors where the height exceeds 350 mm.

Technical Specifications

| Specification | Details |

|---|---|

| Conveyor Width | 970 mm, 1170 mm, 1370 mm |

| Chains | 3/4″ pallet chain with straight side plates |

| Payload | Max. 1500 kg per pallet |

| Standard Height | 350 mm |

| Gear Motor | Chain conveyor 0.55 kW, Lifting unit 0.37 kW |

| Chain Distance | 700 mm |

| Transfer Speed | 11.4 m/min (other speeds available) |

| Motors | Two motors—one for up/down movement, one for chain movement |

Item Numbers

| Conveyor Width | Item No. (Motor Mounted Right Side) | Item No. (Motor Mounted Left Side) |

|---|---|---|

| 970 mm | 471221731 | 471221732 |

| 1170 mm | 471222731 | 471222732 |

| 1370 mm | 471223731 | 471223732 |

Benefits

- Efficiency: Automates the transfer of pallets between conveyor lines, reducing manual labor and increasing throughput.

- Flexibility: Suitable for a wide range of pallet sizes and conveyor configurations.

- Reliability: Dual motor system ensures consistent and reliable operation.

- Safety: Automated operation minimises the risk of work-related injuries associated with manual pallet handling.

- Integration: Easily integrates with existing conveyor systems, enhancing overall material handling efficiency.

Applications

SOCO Transfer Units are ideal for:

- Warehouses: Facilitating the efficient transfer of pallets between different storage and retrieval systems.

- Manufacturing Plants: Streamlining the movement of materials between production lines and packaging areas.

- Distribution Centres: Enhancing the flow of goods for shipping and receiving operations.

- Logistics Operations: Improving the overall efficiency of material handling processes.

Conclusion

SOCO Transfer Units offer a robust and efficient solution for automating the transfer of pallets between different conveyor lines. Their high payload capacity, dual motor system, and versatile integration capabilities make them an excellent choice for optimising material handling processes in various industrial and commercial settings. Whether you’re managing a warehouse, manufacturing plant, or distribution centre, SOCO Transfer Units ensure smooth, reliable, and efficient pallet transfer.

For more detailed information and to explore how SOCO Transfer Units can benefit your operations, please contact us.

Datasheet

Specifications | |

|---|---|

Payload | Max. 1500 kg per pallet. |

Standard height | 350 mm. |

Gear motor | Chain conveyor 0.55 kW. Lifting unit 0.37 kW. |

Chains | 3/4″ pallet chain with straight side plates. |

Chain distance | 700 mm. |

Standard width | 970 mm, 1170 mm, and 1370 mm. |

Transfer speed | 11.4 m/min (other speeds available). |

Subject to alteration. | |