SOCO Pack OAB case erector – for cases with automatic bottom lock

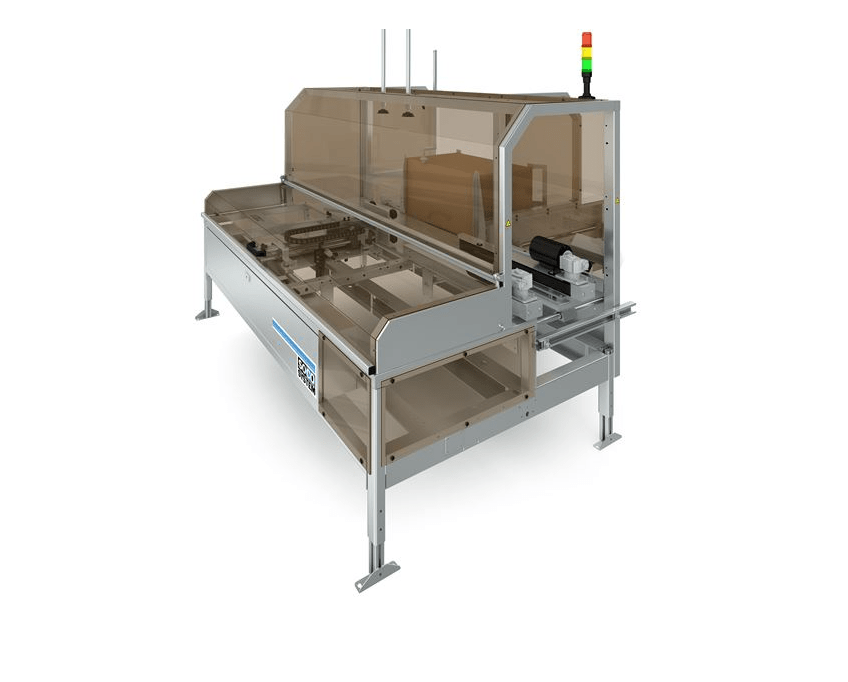

Erects the case and prepares it for filling. SOCO Pack OAB is a high speed, fully automatic case erector. The machine can erect cases in different sizes with automatic bottom lock. Switching to a new box size is quick and easy. The maximum capacity of the OAB case erector is up to 12 cases per minute. The pneumatic parts of the case erector are from Festo, and the PLC is Siemens.

Erects the case and prepares it for filling. SOCO Pack OAB is a high speed, fully automatic case erector. The machine can erect cases in different sizes with automatic bottom lock. Switching to a new box size is quick and easy. The maximum capacity of the OAB case erector is up to 12 cases per minute. The pneumatic parts of the case erector are from Festo, and the PLC is Siemens.

- Compact machine.

- User friendly software with many options.

- Low noise level and low air consumption.

The SOCO SYSTEM case erector is the perfect start of the packaging line – improves ergonomics and increases productivity and automation.

SOCO Pack OAB case erector – for cases with automatic bottom lock

Overview

The SOCO Pack OAB Case Erector is a high-speed, fully automatic machine designed specifically for erecting cases with an automatic bottom lock. This case erector is ideal for high-volume packaging operations, providing efficiency and reliability in the case forming process.

Key Features

- High-Speed Operation: Capable of erecting up to 12 cases per minute, making it suitable for high-volume packaging needs.

- Fully Automatic: Automates the process of erecting cases with an automatic bottom lock, reducing manual labor and increasing productivity.

- Handles Various Case Sizes: Can erect cases in different sizes, providing flexibility for various packaging requirements.

- Quick and Easy Size Switching: Allows for quick and easy switching to a new box size, enhancing operational efficiency.

- Robust Construction: Built to withstand rigorous industrial use, ensuring long-term reliability.

- User-Friendly Interface: Equipped with an intuitive control panel for easy operation and adjustments.

Technical Specifications

| Specification | Details |

|---|---|

| Model | SOCO Pack OAB |

| Capacity | Up to 12 cases per minute |

| Case Construction | FEFCO 0201, Corrugated Board |

| Material Thickness | Suitable for various thicknesses |

| Magazine Capacity | High capacity for continuous operation |

| Power Supply | Standard industrial power requirements |

| Power Consumption | Not specified |

| Air Consumption | Not specified |

| Air Pressure | Not specified |

| Noise Level | Not specified |

| Standard Colour | Not specified |

| Case Dimensions | Adjustable for different sizes |

| Machine Dimensions | Not specified |

| Weight | Not specified |

Benefits

- Efficiency: Automates the case erecting process, significantly reducing manual labor and increasing throughput.

- Flexibility: Handles a wide range of case sizes and materials, making it adaptable to various packaging needs.

- Safety: Designed to meet CE safety standards, ensuring a safe working environment.

- Ease of Use: User-friendly controls and easy adjustments make the machine simple to operate and maintain.

- Productivity: High-speed operation and continuous magazine filling ensure uninterrupted packaging processes.

Applications

The SOCO Pack OAB Case Erector is perfect for:

- Warehouses: Efficiently erecting cases for storage and shipping.

- Manufacturing Plants: Streamlining end-of-line packaging processes.

- Distribution Centres: Ensuring secure packaging of goods for transportation.

- Logistics Operations: Enhancing the efficiency of packaging and handling processes.

Conclusion

The SOCO Pack OAB Case Erector offers a comprehensive and efficient solution for high-speed automatic case erecting with an automatic bottom lock. Its advanced features, robust construction, and compliance with safety standards make it an excellent choice for various industrial and commercial applications. Whether you need to streamline your packaging operations or enhance the efficiency of your end-of-line processes, the SOCO Pack OAB delivers reliable and high-performance case erecting.

For more detailed information and to explore how the SOCO Pack OAB Case Erector can benefit your operations, please contact us.

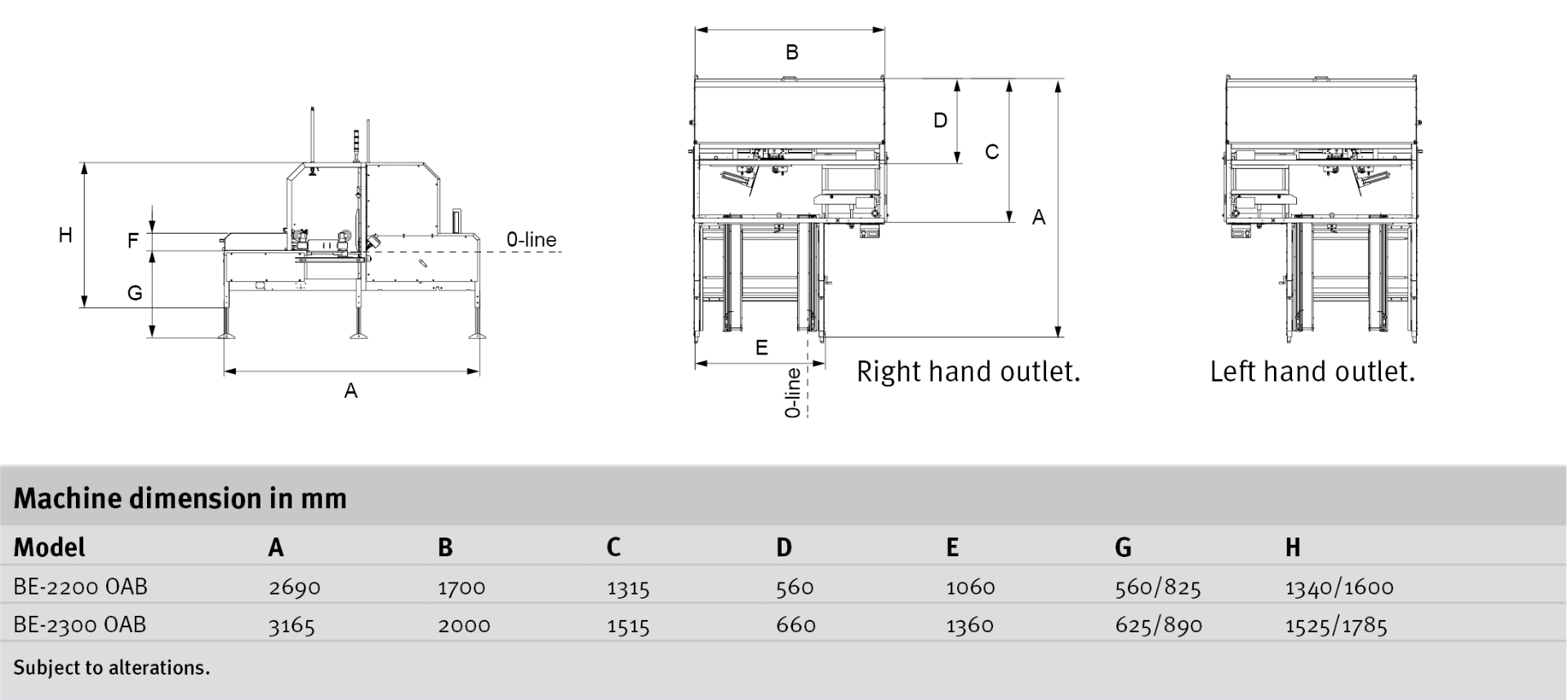

Datasheet

Specifications | |

|---|---|

Capacity cases/min. | Up to 12*. |

Case construction | Cases with automatic bottom lock. |

Case material | Corrugated board thickness 2.0 – 7.0 mm (a- b- c- b/c-flute). |

Case cardboard magazine capacity | Approx. 190 pcs in c-flute. |

Suction plate | Interchangeable suction plate. The machine is delivered with one vacuum head as standard. |

Electrical specifications | 0.5 kW, 400 V, 50 Hz, 3 phases, with earth. |

Air consumption | 31 l free air/cycle, min 600 kPa, 1/2″ connection. |

Noise level | Max. 74 dBa. |

Colour | As standard, the case erector is supplied in RAL-9006 (light grey). |

Queue control | Queue control is standard. |

*Depending on the quality, construction, and size of the case. The machine is delivered with Siemens PLC and Festo pneumatic parts as standard. Subject to alteration. | |