SOCO Pack AHS case erector – Hot melt

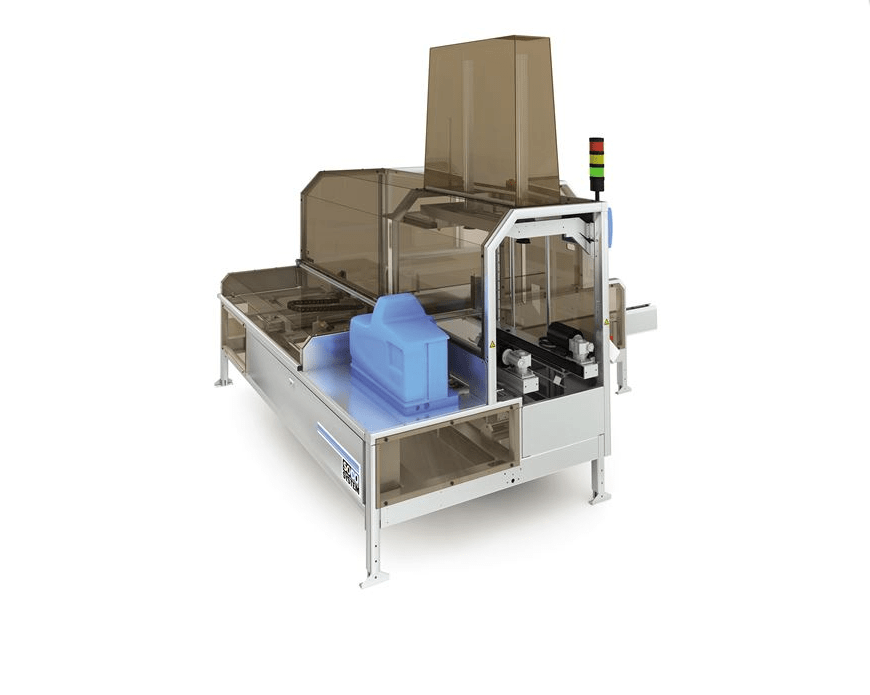

Erects the case and bottom seals it with hot melt – ready for filling. SOCO Pack AHS is a high speed, fully automatic case erector with integrated hot melt bottom sealer. The machine handles FEFCO 0201 cases as standard. As one of several additional functions, the case erector can be fitted with a side flap spreader if cases are causing problems due to poor design or material quality. The machine is also available partly in stainless steel.

The SOCO SYSTEM case erector is the perfect start of the packaging line – improves ergonomics and increases productivity and automation. The pneumatic parts of the case erector are from Festo, and the PLC is Siemens.

- Compact machine.

- Easy installation.

- User-friendly software with numerous possibilities.

- Low noise level and low air consumption.

SOCO Pack AHS case erector – Hot melt

Overview

The SOCO Pack AHS Case Erector with Hot Melt is a high-speed, fully automatic machine designed to erect and bottom-seal cases using hot melt adhesive. This case erector is ideal for high-volume packaging operations, providing efficiency and reliability in the packaging process.

Key Features

- High-Speed Operation: Capable of erecting up to 12 cases per minute, making it suitable for high-volume packaging needs.

- Fully Automatic: Automates the process of erecting and bottom-sealing cases with hot melt adhesive, reducing manual labor and increasing productivity.

- Integrated Hot Melt Sealer: Ensures secure and consistent sealing of the bottom of the cases using hot melt adhesive.

- Handles FEFCO 0201 Cases: Standard configuration for handling FEFCO 0201 cases, which are commonly used in various industries.

- Adjustable for Different Case Sizes: User-friendly adjustments allow for easy switching between different case sizes.

- Powered Case Magazine: The magazine is easy to fill, even while the machine is in operation, ensuring continuous productivity.

- Efficient Flap Folding and Glue Application: Ensures reliable case formation and secure sealing.

Technical Specifications

| Specification | Details |

|---|---|

| Model | BE-2200 AHS |

| Capacity | Up to 12 cases per minute |

| Case Construction | FEFCO 0201, Corrugated Board |

| Material Thickness | 2.0 to 7.0 mm |

| Magazine Capacity | Approx. 190 pcs in C-flute |

| Power Supply | 230 V / 3 x 400 V, 50 Hz / 60 Hz |

| Power Consumption | 4.5 kW |

| Air Consumption | 65.5 to 72.5 l free air/cycle |

| Air Pressure | 600 kPa |

| Noise Level | 74 dBA |

| Standard Color | RAL-9006 (light grey) |

| Case Dimensions | Minimum: 180 x 130 x 100 mm |

| Maximum: 450 x 300 x 450 mm | |

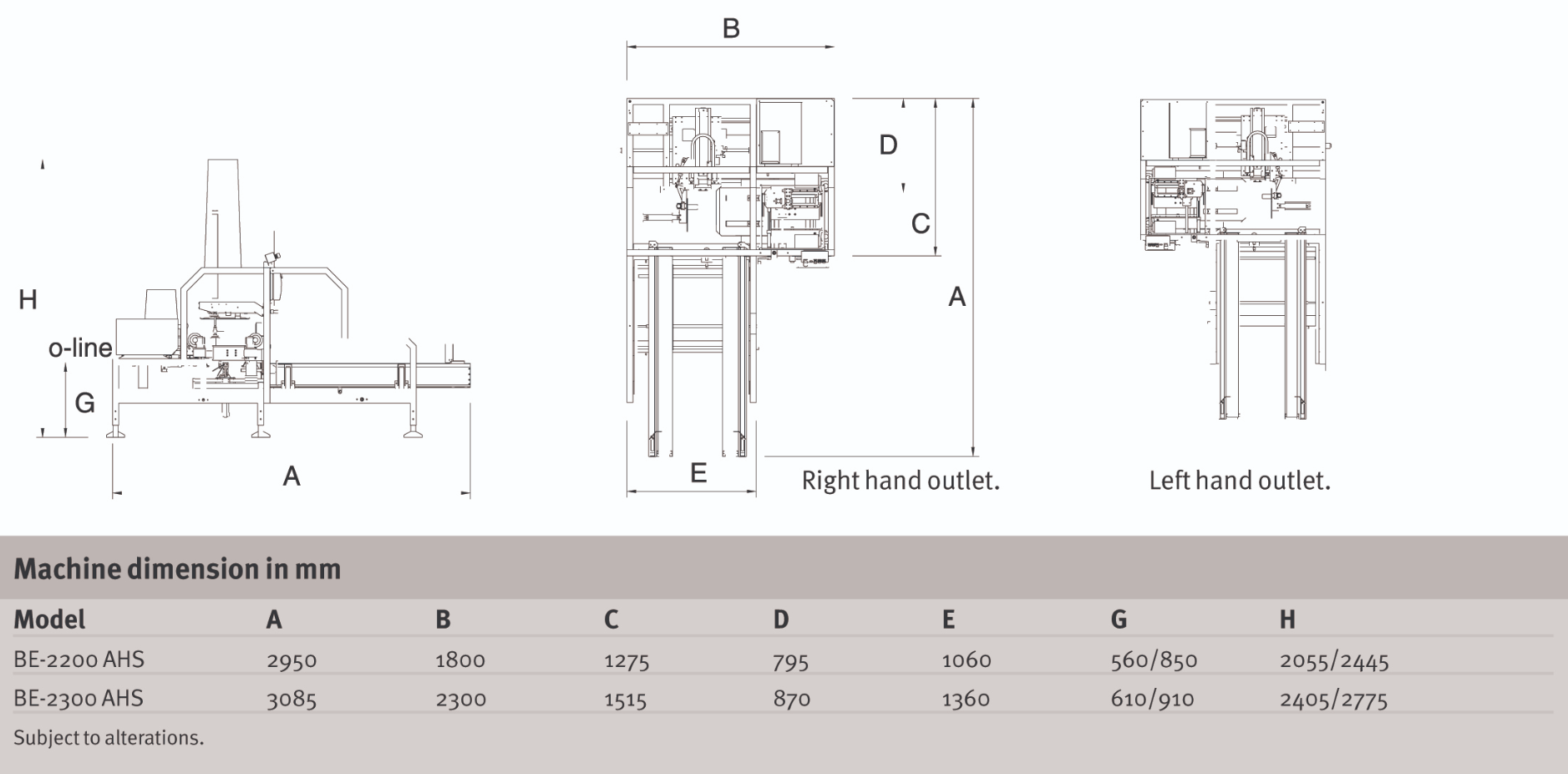

| Machine Dimensions | 2950 x 1800 x 1275 mm |

| Weight | Not specified |

Benefits

- Efficiency: Automates the case erecting and sealing process, significantly reducing manual labor and increasing throughput.

- Flexibility: Handles a wide range of case sizes and materials, making it adaptable to various packaging needs.

- Safety: Designed to meet CE safety standards, ensuring a safe working environment.

- Ease of Use: User-friendly controls and easy adjustments make the machine simple to operate and maintain.

- Productivity: High-speed operation and continuous magazine filling ensure uninterrupted packaging processes.

Applications

The SOCO Pack AHS Case Erector with Hot Melt is perfect for:

- Warehouses: Efficiently erecting and sealing cases for storage and shipping.

- Manufacturing Plants: Streamlining end-of-line packaging processes.

- Distribution Centers: Ensuring secure packaging of goods for transportation.

- Logistics Operations: Enhancing the efficiency of packaging and handling processes.

Conclusion

The SOCO Pack AHS Case Erector with Hot Melt offers a comprehensive and efficient solution for high-speed automatic case erecting and sealing. Its advanced features, robust construction, and compliance with safety standards make it an excellent choice for various industrial and commercial applications. Whether you need to streamline your packaging operations or enhance the efficiency of your end-of-line processes, the SOCO Pack AHS delivers reliable and high-performance case erecting and sealing.

For more detailed information and to explore how the SOCO Pack AHS Case Erector with Hot Melt can benefit your operations, please contact us.

Datasheet

Specifications | |

|---|---|

Capacity cases/min. | Up to 12*. |

Case construction | FEFCO 0201. Other constructions available on demand. |

Case material | Corrugated board thickness 2.0 – 7.0 mm (a- b- c- b/c-flute). |

Case cardboard magazine capacity | Approx. 190 pcs in b-flute. |

Suction plate | Interchangable suction plate. |

Electrical specifications | 4.5 kW, 3 x 400/230 V + PE, 50/60 Hz. |

Air consumption | 65.5 – 72.5 l free air/cycle, min 600 kPa, 1/2″ connection. |

Noise level | Max. 74 dBa. |

Colour | As standard, the case erector is supplied in RAL-9006 (light grey). |

Queue control | Queue control is standard. |

Hot-melt equipment | Nordson Problue 4 kg as standard. |

*Depending on the quality, construction, and size of the case. The machine is delivered with Siemens PLC and Festo pneumatic parts as standard. Subject to alteration. | |