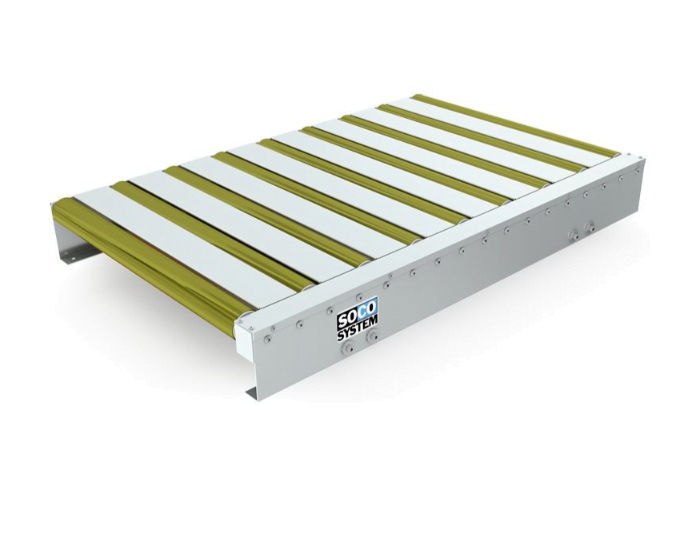

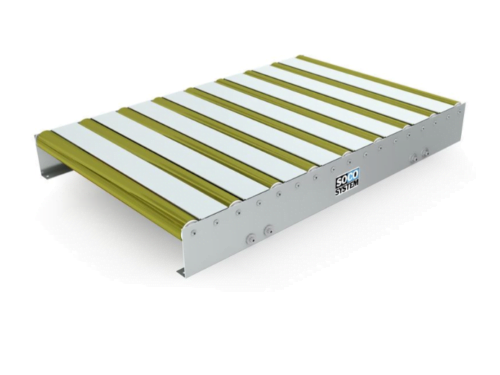

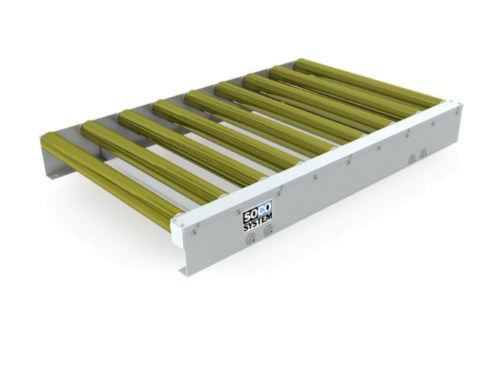

SOCO Coupled sections with cover plates for driven pallet roller conveyors

For support or floor mounting. The cover plates prevent you from getting caught between the rollers.

For support or floor mounting. The cover plates prevent you from getting caught between the rollers.

SOCO Coupled sections with cover plates for driven pallet roller conveyors

Overview

SOCO Coupled Sections with cover plates for driven pallet roller conveyors are designed to extend the functionality and length of existing conveyor systems while ensuring safety and efficiency. These coupled sections are particularly useful for handling EUR 1/2 and 1/4 pallets made of wood or plastic. The cover plates provide an added layer of safety by preventing personnel from getting caught between the rollers.

Key Features

- Simplex Chain Design: Features a simplex chain configuration, providing robust and reliable performance.

- High Payload Capacity: Capable of handling a maximum payload of 1500 kg per conveyor.

- Versatile Applications: Suitable for EUR 1/2 and 1/4 pallets, accommodating both wood and plastic materials.

- Cover Plates: Prevent personnel from getting caught between the rollers, enhancing safety.

- Standard Widths: Available in standard widths of 750 mm and 950 mm, designed to fit 800 mm x 1200 mm pallets traveling with either side leading.

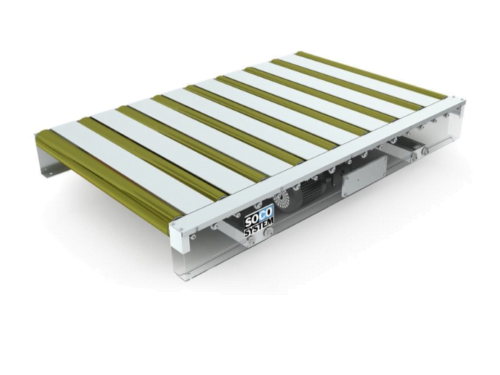

- Automatic Operation: The chain conveyor is raised and lowered automatically above and below roller height, ensuring seamless integration with existing conveyor systems.

- Dual Motors: Equipped with two motors—one for the up/down movement and one for the chain movement—providing reliable and efficient operation.

Technical Specifications

| Specification | Details |

|---|---|

| Conveyor Width | 750 mm, 950 mm |

| Length Options | Customisable to fit existing systems |

| Chains | 3/4″ pallet chain with straight side plates |

| Payload | Max. 1500 kg per conveyor and motor unit |

| Standard Height | Supports available for standard heights from 225 mm to 650 mm. Other heights available on request. |

| Gear Motor | 0.37 kW worm reduction gear fixed to the conveyor frame |

| Speed | 11.4 m/min (other speeds available) |

| Chain Distance | Approx. 700 mm for 750 mm width, Approx. 900 mm for 950 mm width |

| Surface Treatment | Electro-galvanised steel with yellow chromating |

Benefits

- Efficiency: Streamlines the transportation of pallets, reducing manual handling and increasing productivity.

- Safety: Cover plates prevent accidents by ensuring personnel cannot get caught between rollers.

- Flexibility: Suitable for various pallet sizes and materials, making it adaptable to different industrial needs.

- Durability: Constructed to withstand rigorous industrial use, ensuring long-term reliability.

- Ease of Integration: Designed to be easily coupled with existing conveyor systems, enhancing overall material handling efficiency.

Applications

SOCO Coupled Sections with cover plates for driven pallet roller conveyors are ideal for:

- Warehouses: Facilitating efficient pallet transportation between storage and retrieval systems.

- Manufacturing Plants: Streamlining the movement of materials and products between production lines and packaging areas.

- Distribution Centres: Enhancing the flow of goods for shipping and receiving operations.

- Logistics Operations: Improving the overall efficiency of material handling processes.

Conclusion

SOCO Coupled Sections with cover plates for driven pallet roller conveyors offer a robust and efficient solution for extending the functionality and length of your existing conveyor systems. Their high payload capacity, stable performance, and versatile applications make them an excellent choice for optimising material handling processes. Whether you’re managing a warehouse, manufacturing plant, or distribution centre, these coupled sections ensure smooth, reliable, and efficient pallet transfer while enhancing safety.

For more detailed information and to explore how SOCO Coupled Sections with cover plates for driven pallet roller conveyors can benefit your operations, please contact us.

Datasheet

Specifications | |

|---|---|

Surface treatment | Electro galvanised steel with the exception of chains and roller axles. Rollers are electro galvanised with yellow chrome. |

Frames | Cold-bend angle profiles bolted to C-profile cross bars with supports. |

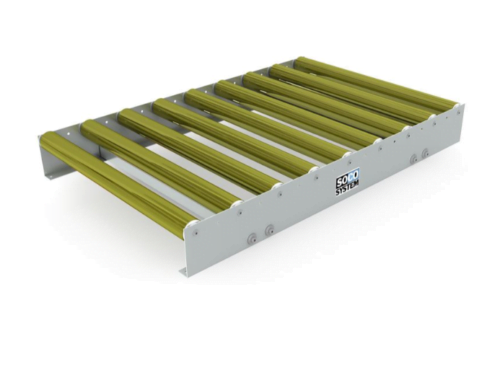

Rollers | Ø 80 mm electro galvanised steel tubes. |

Axle diameter | Ø 17 mm. |

Bearings | 6203 – 2rs. |

Roller fittings | Rollers are suspended between side frames by means of M10 axle. |

Payload | For use up to 1.000 kg load per pallet and motor unit. Maximum suitable load is determined by several factors like speed of operation, width of conveyor, and shape and width of the pallets. If in doubt, please contact SOCO SYSTEM. |

Standard height | The total height from floor to top of rollers is 190 mm. |

Chain drive | Chains operate beneath roller surface. Chain drive is from roller to roller. 1/2″ sprockets of hardened steel are integrated with the bearing of the roller. |

Chain cover | Chains are protected by a U-profile mounted above the chains. The chain cover is beneath the roller level to ensure access to pallets from both sides of the conveyor. |

Subject to alteration. | |