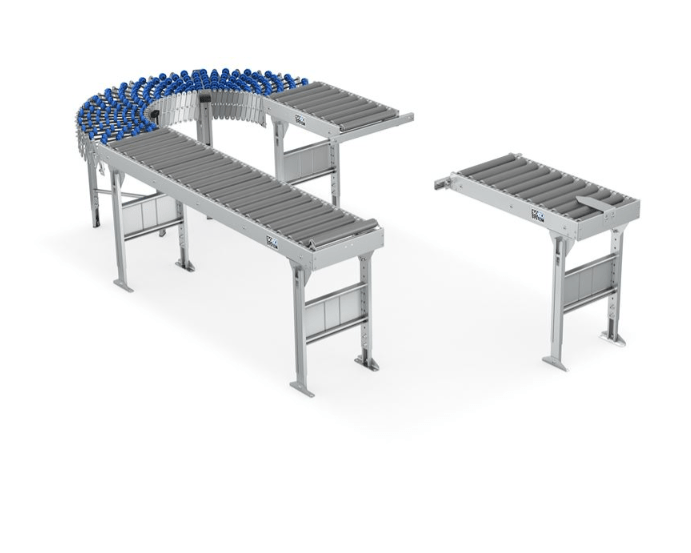

SOCO Boomerang packaging system for case sealers

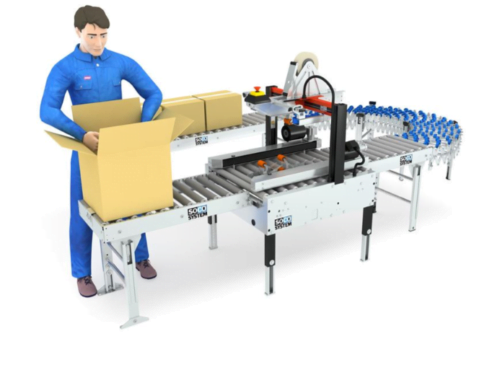

The boomerang system is ideal as a “one-man packing station” where a single operator can fill, seal, and palletise cases from practically the same position. The boomerang packing station allows three operations to be carried out within a very limited area, approx. 8 m2:

1. Case erecting and holding the empty case in place. The operator has both hands free for filling.

2. Case sealing at the top and bottom, the cases then pass onto the conveyor and accumulate directly behind the operator.

3. The cases are palletised when the accumulating conveyor is full.

Delivered complete with supports and coupling fittings. The entire system can be fitted with castors.

Specifications | |

|---|---|

Tubes | Ø 48 mm impact-proof plastic. |

Axles | Ø 8 mm aluminium. |

End bearings | Plastic insert with stainless steel balls. |

Frames | Electro-galvanised steel. |

Axle pitch | As standard, the boomerang system is delivered with a 90 mm pitch. Please contact our sales department if a different pitch is required. |

Width | 300, 400, 500 mm. |

Load | 10 kg per roller. Max. 75 kg per metre conveyor. |

Subject to alteration. | |