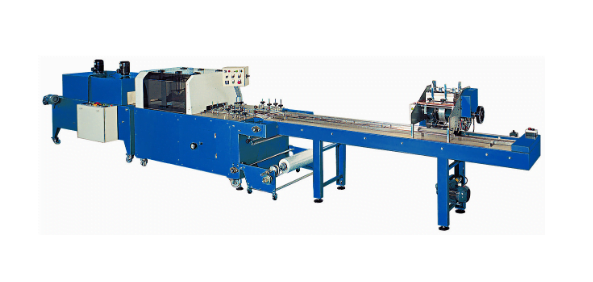

Italdibipack Speed Bag HS

![]()

HIGH-SPEED AUTOMATIC HORIZONTAL BAGGING SYSTEM

Italdibipack’s automatic solution for customers who have remarkable outputs: an absolutely up-to-date bagging system equipped with innovative patented devices that grant high speed and excellent performance and offer great flexibility in applications in different commercial fields.

Speed Bag HS

Italdibipack Speed Bag HS

Overview

The Italdibipack Speed Bag HS is a high-speed horizontal packing machine designed for efficient and rapid packaging of magazines, newspapers, and other printed materials. This advanced machine offers exceptional productivity and reliability, making it an ideal choice for high-volume packaging operations in the publishing and distribution industries.

Key Features

- High-Speed Operation: Capable of processing up to 4,000 pieces per hour, ensuring rapid packaging for large-scale operations.

- Horizontal Flow-Pack Design: Utilises HFFS (Horizontal Form-Fill-Seal) technology for efficient and consistent packaging.

- Fully Automatic: Requires minimal operator intervention, maximising productivity and reducing labour costs.

- Versatile Applications: Ideal for wrapping magazines, newspapers, catalogues, and wholesale publications.

- Large Capacity: Designed to handle high-volume packaging needs with ease.

Technical Specifications

- Power Supply: 240 V – 1 Ph – 50/60 Hz

- Power Required: 2 KW

- Overall Machine Dimensions (L x W x H): 5700 x 1100 x 1500 mm

- Machine Weight: 700 kg

- Minimum Wrapping Size: Capable of handling various sizes, including standard A4 publications

- Maximum Throughput: Up to 4,000 pieces per hour

Benefits

- Increased Efficiency: High-speed operation and automatic functionality significantly enhance overall productivity.

- Consistency: Ensures uniform and professional packaging for all products.

- Versatility: Suitable for a wide range of printed materials, offering flexibility in packaging operations.

- Space Optimisation: Despite its high capacity, the machine has a relatively compact footprint for its capabilities.

- Cost-Effective: High-speed operation and minimal operator requirements lead to reduced per-unit packaging costs.

Applications

The Italdibipack Speed Bag HS is perfect for businesses in the publishing and distribution sectors, including:

- Newspaper Printing Plants: Rapid packaging of daily newspapers for distribution.

- Magazine Publishers: Efficient wrapping of periodicals and magazines.

- Catalogue Distributors: High-speed packaging of catalogues and wholesale publications.

- Commercial Printing Facilities: Packaging of various printed materials, especially those in A4 size.

Conclusion

The Italdibipack Speed Bag HS stands out as a reliable and highly efficient solution for high-volume horizontal packaging needs. Its combination of speed, automation, and versatility makes it an excellent choice for businesses looking to optimise their packaging operations for printed materials. Invest in the Speed Bag HS to significantly enhance your packaging productivity and ensure consistent, high-quality wrapping of your publications.

Please feel free to contact us for more detailed information and to explore how the Speed Bag HS can benefit your operations.

- Power supply: 2440 V – 1 Ph – 50/60 Hz

- Power required: 2 KW

- Overall machine dimensions L x W x H: 5700 x 1100 x 1500 mm

- Weight: 700 Kg

- Min wrapping size L x W x H: 120 x 150 x 1 mm

- Max wrapping size L x W x H: 400 x 280 x 40 mm

- Film roll width: 650 mm

- Compressed air supply: 130 l/min – 6 bar

- Output up to: 4000 pcs/h

Notes: Technical data subject to variations without prior notice

Output depends on the operator and the type of the package

Conceived and designed by Italdibipack R&D Team who guarantees the best manufacturing standards, high quality components and ease of operation. Ideal for wrapping newspapers and magazines, catalogues and wholesale publications, manuals and any commercial printed matters, but also books, cards, CDs, DVDs, VHS and so on, thanks to different types of feeders and options. The machine works with transparent or printed LLDPE (thickness 15 ÷ 40).

Machine made according to CE rules.