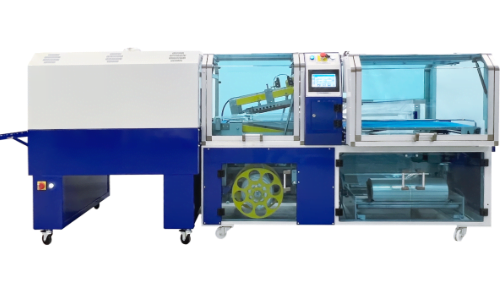

Italdibipack Mecpack STX

![]()

AUTOMATIC SHRINK WRAPPING MACHINE WITH HIGH QUALITATIVE AND WORKING STANDARDS

High-quality standard fully automatic “L”-sealers for high performances in any application fields and with any product dimensions. Ideal for high output requirements.

They work full automatically: the only thing the operator has to do is just to put the products on the in-feed conveyor because a system of photo-eyes controls the whole wrapping process by itself. The change of product size is very easy.

Mecpack STX

Italdibipack Mecpack STX

Overview

The Italdibipack Mecpack STX is a high-quality, fully automatic “L”-sealer designed for high-performance packaging in various application fields. This machine is ideal for businesses requiring efficient and reliable shrink wrapping for products of different dimensions. The Mecpack STX combines advanced technology with user-friendly features, making it an excellent choice for high-output packaging operations.

Key Features

- Fully Automatic Operation: The Mecpack STX operates fully automatically, requiring the operator only to place products on the in-feed conveyor. A system of photo-eyes controls the entire wrapping process.

- High Throughput: Capable of handling up to 1,700 pieces per hour, making it suitable for high-output requirements.

- Sealing Control: Features a timer-controlled sealing process with separate electronic controls for sealing temperature and sealing bars.

- Photo-Eye Detection: Equipped with horizontal and vertical photo-eyes to detect product length and ensure accurate wrapping.

- Powered Conveyors: Includes powered in-feed and out-feed conveyors for smooth product handling.

- Scrap Rewinding: Features powered scrap-rewinding to manage film waste efficiently.

- Film Handling: Utilises driven chains for film pulling and can work with centerfolded polyolefin hot thermo-sealing and shrinkable films.

- Adjustable Settings: Easy change of product size and settings to accommodate different packaging needs.

- Optional Features: Rolling-rods tunnel and “kissing” conveyors for packing small dimension products, castors for mobility, and compliance with CE standards.

Technical Specifications

- Operational Mode: Fully automatic

- Sealing Type: L-sealer with shrink tunnel

- Film Width: Maximum 550 mm

- Throughput: Up to 1,700 pieces per hour

- Power Supply: 240V – 1ph – 50/60 Hz

- Machine Dimensions (L x W x H): 1800 x 1000 x 1500 mm (approximate)

- Film Compatibility: Centerfolded polyolefin hot thermo-sealing and shrinkable films

Benefits

- High Efficiency: Fully automatic operation streamlines the packaging process, reducing manual labour and increasing productivity.

- Consistency: Ensures uniform and professional packaging with precise control over sealing parameters.

- Versatility: Suitable for a wide range of products, offering flexibility in packaging operations.

- Durability: Robust construction ensures long-term reliability and minimal maintenance.

- User-Friendly: Easy to operate with simple adjustments for different product sizes and settings.

Applications

The Italdibipack Mecpack STX is perfect for businesses in various sectors, including:

- Food and Beverage Industry: Packaging of multipacks of beverages, canned goods, and other food products.

- Consumer Goods: Wrapping of household items, personal care products, and other consumer goods.

- Industrial Products: Suitable for packaging technical articles and industrial components.

- Shipping and Logistics: Provides protection and safety for bundled products during shipping.

Conclusion

The Italdibipack Mecpack STX stands out as a highly efficient and reliable solution for automatic shrink wrapping needs. Its combination of advanced features, user-friendly design, and robust construction makes it an excellent choice for businesses looking to optimise their packaging operations. Invest in the Mecpack STX to significantly enhance your packaging productivity and ensure consistent, high-quality wrapping of your products.

Please feel free to contact us for more detailed information and to explore how the Mecpack STX can benefit your operations.

- Power supply – 240- 380 V 3 Ph

- Power required – 1,5 KW

- Overall machine dimensions L x W x H – 1800 x 980 x 1450 mm

- Working plate height – 780 mm

- Machine weight – 420 kg

- Minimum sealing dimensions L x W – 90 x 90 mm

- Maximum sealing dimensions L x W – 550 x 450 mm

- Maximum product height – 150 mm

- Minimum film width – 200 mm

- Maximum film width – 550 mm

- Compressed air consumption – 0,5 Nl/cycle

- Compressed air pressure – 6 bar

- Output – Up to 1700 pcs/h

SPECIFICATIONS – TUNNEL 5525 1100 AX

- Power supply – 380 V 3 Ph

- Power required – 7 KW

- Overall machine dimensions L x W x H – 1400 x 850 x 1420 mm

- Working plate height – 780 mm

- Tunnel entrance dimensions W x H – 450 x 200 mm

- Tunnel lenght – 700 mm

- Machine weight – 260 kg

Notes: Technical data subject to variations without prior notice

Output depends on the operator and the type of the package

- Sealing controlled by a timer.

- Separated electronic control for sealing-temperature and sealing-bars

- Product length detected by photo-eyes with horizontal and vertical reading

- Powered infeed/outfeed conveyor

- Powered scrap-rewinding

- Film-pulling by driven chains

- “kissing” conveyors in order to pack product of small dimensions

- Rolling-rods tunnel on request

- Castors

- Centerfolded polyolefin hot thermo-sealing and also shrinkable films (GREEN FILM – GOLDEN FILM)

Machine made according to CE rules