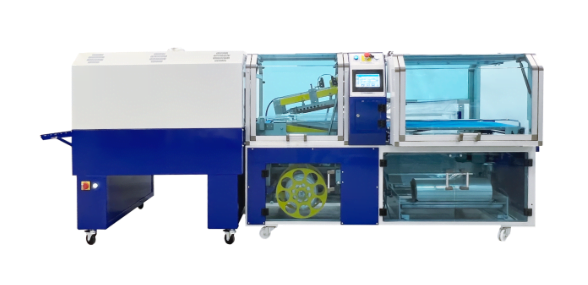

Italdibipack Mecpack Five Stars Line

![]()

AUTOMATIC L-SEALER LINE: VERY HIGH TECHNOLOGICAL LEVEL

The new MECPACK FIVE STARS TOUCH is the result of over 40 years manufacturing and applicative experience of Italdibipack Group in automatic l-sealers.

Design simple but modern, innovative technology, attention to detail, extremely easy to use and extremely functional. Mec pack Five Stars combined with shrink tunnel 5525 EV, built with rods in special fiber, is an automatic packaging line compact and efficient. Possibility of connection modules for on-line assistance and for industrial production management control 4.0.

Mecpack Five Stars Touch

Italdibipack Mecpack Five Stars Line

Overview

The Italdibipack Mecpack Five Stars Line is a high-performance, fully automatic “L”-sealer designed for efficient and reliable shrink wrapping. This line combines advanced technology with user-friendly features, making it ideal for businesses with high-output requirements. The Mecpack Five Stars Line is suitable for a variety of packaging applications, ensuring consistent and professional results.

Key Features

- Automatic Operation: Fully automatic “L”-sealer with integrated shrink tunnel for seamless packaging.

- Teflon-Coated Sealing Blade: Ensures clean and precise seals with minimal maintenance.

- Photo-Eye Detection: Automatically determines pack bag length through horizontal or vertical photo-eyes, depending on the product shape.

- High Throughput: Capable of handling up to 1,700 pieces per hour, making it suitable for high-output requirements.

- User-Friendly Control Panel: Equipped with a touch-screen control panel for easy operation and monitoring of all functions.

- Compact Design: Despite its high performance, the machine maintains a compact footprint, optimising space utilisation.

Technical Specifications

- Power Supply: 240V – 1ph – 50/60 Hz

- Sealing Bar Dimensions: Customisable to fit different product sizes

- Maximum Film Width: 550 mm

- Throughput: Up to 1,700 pieces per hour

- Film Compatibility: Works with centerfolded polyolefin hot thermo-sealing and shrinkable films

- Machine Dimensions (L x W x H): 1800 x 1000 x 1500 mm (approximate)

Benefits

- High Efficiency: Fully automatic operation streamlines the packaging process, reducing manual labour and increasing productivity.

- Consistency: Ensures uniform and professional packaging with precise control over sealing parameters.

- Versatility: Suitable for a wide range of products, offering flexibility in packaging operations.

- Durability: Robust construction ensures long-term reliability and minimal maintenance.

- User-Friendly: Easy to operate with a touch-screen control panel and simple adjustments for different product sizes and settings.

Applications

The Italdibipack Mecpack Five Stars Line is perfect for businesses in various sectors, including:

- Food and Beverage Industry: Packaging of multipacks of beverages, canned goods, and other food products.

- Consumer Goods: Wrapping of household items, personal care products, and other consumer goods.

- Industrial Products: Suitable for packaging technical articles and industrial components.

- Shipping and Logistics: Provides protection and safety for bundled products during shipping.

Conclusion

The Italdibipack Mecpack Five Stars Line stands out as a highly efficient and reliable solution for automatic shrink wrapping needs. Its combination of advanced features, user-friendly design, and robust construction makes it an excellent choice for businesses looking to optimise their packaging operations. Invest in the Mecpack Five Stars Line to significantly enhance your packaging productivity and ensure consistent, high-quality wrapping of your products.

Please feel free to contact us for more detailed information and to explore how the Mecpack Five Stars Line can benefit your operations.

- Power supply voltage: 240/400 V – 3PH – N

- Installed power: 2.5 kW

- Overall dimensions: 2000 x 1000 x 1360 (h) mm

- Sealing bars dimensions: 600 x 500mm

- Max product height: 180 mm

- Conveyor belt speed: 22 m / min

- Productivity: up to 2200 pcs / h

- Max roll width: 600 mm x 250 mm

- Compressed air consumption: 6 Nl / p

- Compressed air: 6 bar

- Weight: 540 kg

- Electronic control panel (by R&D Italdibipack)

SPECIFICATIONS – MECPACK FIVE STARS TOUCH

- Power supply voltage: 240/400 V – 3PH – N

- Installed power: 2.5 KW

- Overall dimensions (LxWxH): 2000 x 1000 x 1360 mm

- Sealing bars dimensions: 600 x 500mm

- Max passage height: 180 mm

- Belt speed: 30 m / min

- Productivity: up to 2400 pcs / h

- Max film width: 600 x 250 mm

- Infeed conveyor height from the floor (machine on wheels): 790 mm

- Compressed air pressure: 6 bar

- Compressed air consumption: 6 N / l cycle

- Weight: 540 Kg

- Touch Display (Mitsubishi Software)

SPECIFICATIONS – MECPACK FIVE STARS BIG

- Power supply voltage: 240/400 V 3PH – N

- Installed power: 3 KW

- Overall dimensions (LxWxH): 2400 x 1200 x 1360 mm

- Sealing bars dimensions: 800 x 600 mm

- Min product dimensions (WxL): 100 x 100 mm

- Max passage height: 180 mm (220 mm on request)

- Belt speed: 22 m / min

- Productivity: up to 2200 pcs / h

- Max film width: 750 mm

- Roll diameter: 250 mm

- Min film width: 250 mm

- Infeed conveyor height from the floor (machine on wheels): 790 mm

- Compressed air pressure: 6 bar

- Compressed air consumption: 6 N / l cycle

- Electronic control panel (by R% D Italdibipack)

- Weight: 600 Kg

SPECIFICATIONS – TUNNEL 5525 EV

- Power supply voltage: 240/400 V- 3PH – N

- Installed power: 7 kW

- Dimensions: 1140 x 1000 x 1360 (h) mm

- Tunnel entrance: 550 x 250 mm

- Weight: 230 kg

note: Technical characteristics subjected to variations without previous notifications.

The output depends on the operator and on the overall dimensions of the products.

MECPACK FIVE STARS STD

- Electronic control panel with touch sensitive and intuitive

- operator interface to set and control all the machine functions

- in the best and simplest way (conceived by R&D Italdibipack).

- Possibility to memorize several working cycles with personalized parametres.

- Hot sealing bars (transversal and longitudinal) controlled by two

- independent electronic thermo-regulators.

- Working cycles and parameters setting controlled by microprocessor.

- Teflon coated sealing blade.

- Automatic pack bag length determined through horizontal or

- vertical photo-eye depending from the product shape.

- Multi-pack function (packing of more units in line).

- Infeed conveyor belt with a continuous or synchronised movement with the sealing bar.

- Counter

- Center seal function to save on the film width.

- Motorized film unwinder.

- Micro film performation during the film unwinding.

- Motorized scrap rewinder.

MECPACK FIVE STARS TOUCH

- Machine with electronic control based on a Mitsubishi 32 bIT PLC

- High speed data transmission software (latest Mitsubishi generation) which allows absolute precision of the set working parameters (head / tail / welding / speed times)

- Control of the retraction oven in all its working parameters directly from the display of the welding machine including automatic cooling at shutdown

- Speed regulation and control of inverter motor acceleration and deceleration directly from the display

- Belt conveyor working speed increased up to a maximum of 30 mt/1″

- Welding temperature and retraction oven control system from the PID method ON / OFF method, therefore greater precision and temperature maintenance

- Display control, in manual mode, of product advancement, welding, film pulling and product evacuation

- Diagnostics of alarms and failures and safety interventions readable on the display (over 40 different controls)

- Possibility to control the number of pieces produced in decrement with display of both partial and total production

- Over 100 programs that can be stored with all the related work parameters

- End of film control on/off

- Break of film control on/off

- Full scrap rewinder control

- Possibility of synchronization with external loading belt

- Possibility of continuous loading; the loading belt does not stop during welding

- Possibility of continuous loading; the exit belt does not stop during welding

- Possibility to perform multiple packs, that is, to count the products on arrival before welding the envelope

- Possibility to exclude the execution of the weld to allow the continuous passage of the products

- Possibility to execute a timed envelope, that is to say, instead of delegating the reading of the product length to the photocell, check it giving a time from the arrival of the product (useful for example in the case of strangely shaped products not completely readable by the photocells)

Machine made according to CE rules.