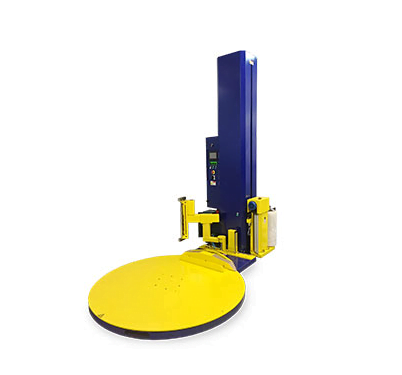

Italdibipack Ecospir TS EV

![]()

The Ecospir line offers also a pallet-wrapper with open turn-table in order to enable loading with manual or electric jacks, so there is no need either for floor modifications or for a ramp.

Ecospir TS EV

Italdibipack Ecospir TS EV

Overview

The Italdibipack Ecospir TS EV is a state-of-the-art semi-automatic pallet-wrapping machine designed to streamline and enhance your packaging operations. Featuring an open turntable for easy loading and unloading, this machine is ideal for businesses that require efficient and reliable pallet wrapping. The Ecospir TS EV combines advanced technology with user-friendly features to ensure consistent and secure wrapping of pallets.

Key Features

- Open Turntable Design: Facilitates easy loading and unloading of pallets, improving workflow efficiency.

- Touch Screen Control Panel: Equipped with an intuitive touch screen interface for rapid setting and regulation of various parameters.

- Customisable Wrapping Cycles: Pre-setting of 8 different working cycles, each with customisable parameters to meet specific packaging needs.

- Automatic and Manual Modes: Offers the flexibility to choose between automatic or manually controlled working procedures.

- Advanced Film Carriage: Features a film carriage driving motor integrated in the mast and chain transmission for reliable performance.

- Safety Systems: Includes a safety system on the bottom side of the film carriage frame to stop its descent in case of obstacles and a photocell to detect wrapping height automatically.

- Adjustable Film Carriage Speed: Controlled through an inverter with separate parameters for ascent and descent, ensuring optimal wrapping.

- Reinforced Turntable: Turntable rotation with hard rubber-covered wheels powered by a chain transmission, designed for durability and stability.

Technical Specifications

- Turntable Diameter: 1500 mm

- Maximum Load Capacity: 1200 kg

- Maximum Wrapping Height: 2200 mm (optional extended mast for 2700 mm)

- Power Supply: 240 V – 1 Ph – 50 Hz

- Power Required: 1 KW

- Machine Dimensions (L x W x H): 1500 x 2440 x 2550 mm

- Film Roll Dimensions: Compatible with standard stretch film rolls up to 500 mm in width

- Weight: Approximately 430 kg

Benefits

- Increased Efficiency: The open turntable design and automatic height detection streamline the wrapping process, enhancing productivity.

- Customisation: Ability to preset and customise multiple wrapping cycles to suit various packaging requirements.

- User-Friendly: The touch screen control panel simplifies operation, reducing the learning curve for new users.

- Safety: Built-in safety systems ensure safe operation, protecting both the machine and the operator.

- Durability: Robust construction and high-quality materials ensure long-lasting performance with minimal maintenance.

Applications

The Italdibipack Ecospir TS EV is perfect for businesses looking to optimise their pallet-wrapping processes. It is particularly well-suited for:

- Manufacturing Plants: Ensuring secure and efficient wrapping of products for shipment.

- Warehouses: Streamlining the bundling and securing of goods.

- Distribution Centres: Facilitating quick and reliable wrapping of packages for distribution.

Conclusion

The Italdibipack Ecospir TS EV stands out as a reliable and efficient solution for semi-automatic pallet-wrapping needs. Its combination of advanced features, user-friendly design, and robust construction makes it an excellent choice for various industrial and commercial packaging applications. Invest in the Ecospir TS EV to enhance your packaging operations and ensure secure, efficient wrapping of your products.

Please feel free to contact us for more detailed information and to explore how the Ecospir TS EV can benefit your operations.

- Maximal wrapping height: 2200 mm

- Turntable diameter: 1500 mm

- Turntable profile (height): 75 mm

- Maximum weight of the load: 1200 Kg

- Film roll dimensions: 500 dimensions wide, with an external diameter of maxim 250 mm on a 3″ core

- Machine gross weight: indicatively 430 kg (referred to the machine in its basic configuration)

- Power supply: 1,5 KW @ 240 V – mono faze + T + N

Notes: Technical data subject to variations without prior notice

Output depends on the type of pallet to be wrapped

- Main control box with “touch screen” type operator panel with a very easy, simple and intuitive use (figures/pictograms), for a rapid setting and regulation of the different parameters

- Pre-setting of 8 different working cycles, each of them with all the parameters customized by the operator

- Machine working controlled through a compact PLC

- Possibility to select an automatic or a manually controlled working procedure

- Possibility to set a number of wrapping cycles in a continuous sequence

- Possibility to select among 3 different methods of wrapping: standard with cross wrapping (during the film carriage ascent and descent); one way wrapping (during the film carriage ascent only); standard cross wrapping with film carriage stop at the top of the load to permit the manual application of a top cover (the film carriage re-start is activated by the operator pressing the related button on the control box)

- Basement with rear predisposal for being lifted and moved with a fork-lift

- Separate setting for the bottom and top reinforcing wraps

- Hinge facility (column/basement) for an easy and fast assembling of the unit

- Film carriage driving motor integrated in the mast (column)

- Film carriage transmission by chain

- Regulation of the film carriage speed, controlled through inverter and with separate parameters for the ascent and descent

- Safety system on the bottom side of the film carriage frame to stop its descent in case of presence of any obstacle

- Automatic detection of the wrapping height through photocell

- Turntable motor protected with a carter

- Regulation of the turntable rotating speed controlled through inverter, with soft start and progressive arrival in the same starting position

- Safety system with photocell, mounted o the open side of the turntable to stop the rotation in presence of a fork-lift of any other obstacle

- Turntable rotation with hard rubber covered wheels powered with a chain transmission

Machine made according to CE rules.