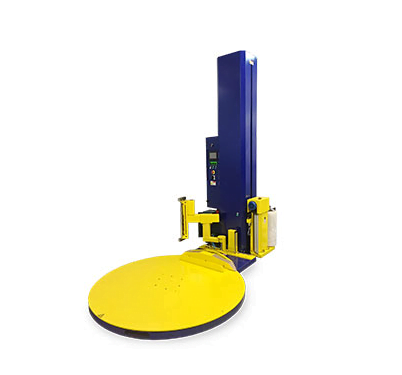

Italdibipack Ecospir Matic

![]()

HEAVY DUTY TURNTABLE MACHINE WITH AUTOMATIC STRETCH-WRAPPING CYCLE

To further widen the range of pallet-wrapping systems, Italdibipack Group has introduced a NEW pallet-wrapper that functions electrically (compressed air is not required) and is equipped with an exclusive cut and clamp device PAT so that the stretch-wrapping cycle is fully automatic.

Italdibipack Ecospir Matic

Overview

The Italdibipack Ecospir Matic is a heavy-duty, automatic stretch-wrapping machine designed to provide efficient and reliable pallet wrapping solutions. This machine is equipped with advanced features that ensure secure and consistent wrapping, making it an ideal choice for high-volume packaging environments. The Ecospir Matic is engineered to stabilize loads early in the wrap cycle and place the ending film tail at the top of the load, enhancing the stability and security of wrapped pallets.

Key Features

- Automatic Operation: Fully automatic stretch-wrapping cycle that minimizes manual intervention and increases productivity.

- Heavy-Duty Turntable: Designed to handle heavy loads, ensuring stability and reliability during the wrapping process.

- Selectable Top Banding Capability: Allows for the stabilization of the load early in the wrap cycle, ensuring secure packaging.

- Film Tail Placement: Places the ending film tail at the top of the load, enhancing load stability and security.

- User-Friendly Interface: Simple controls and touch screen interface make the machine easy to operate, reducing the learning curve for new users.

- Robust Construction: Built with high-quality materials to withstand continuous operation in demanding industrial environments.

Technical Specifications

- Power Supply: 380 V – 3 Ph – 50 Hz

- Power Required: 0.8 KW

- Overall Machine Dimensions (DIA x L x H): 1500 x 2440 x 2550 mm

- Turntable Diameter: 1500 mm

- Maximum Load Height: 2550 mm

- Maximum Load Weight: Up to 1200 kg

- Film Roll Dimensions: Compatible with standard stretch film rolls up to 500 mm in width

Benefits

- Increased Efficiency: Fully automatic operation and high wrapping speeds significantly enhance overall productivity.

- Enhanced Stability: Selectable top banding capability and precise film tail placement ensure secure and stable loads.

- User-Friendly: Simple controls and touch screen interface simplify operation, allowing staff to quickly become proficient with the machine.

- Durability: Robust construction ensures long-lasting performance with minimal maintenance requirements.

- Versatility: Suitable for a wide range of pallet sizes and load types, making it an ideal solution for various packaging needs.

Applications

The Italdibipack Ecospir Matic is perfect for businesses looking to optimise their pallet-wrapping processes. It is particularly well-suited for:

- Manufacturing Plants: Ensuring secure and efficient wrapping of products for shipment.

- Warehouses: Streamlining the bundling and securing of goods.

- Distribution Centres: Facilitating quick and reliable wrapping of packages for distribution.

Conclusion

The Italdibipack Ecospir Matic stands out as a reliable and efficient solution for automatic pallet-wrapping needs. Its combination of advanced features, user-friendly design, and robust construction makes it an excellent choice for various industrial and commercial packaging applications. Invest in the Ecospir Matic to enhance your packaging operations and ensure secure, efficient wrapping of your products.

Please feel free to contact us for more detailed information and to explore how the Ecospir Matic can benefit your operations.

- Power supply: 220V – 1 PH – 50/60 Hz – 20 A

- Overall dimensions: 2900 x 1800 x 2200 mm

- Machine weight: 800 Kg

- Turn-table diameter: 1650 mm

- Maximum pallet dimensions: 1000 x 1200 x 2000 (h) mm

- Maximum pallet weight: 2200 Kg

- Turn-table rotation speed: between 3 and 15 wraps/min

- Maximum roll width: 500 mm

- Output: up to 35 pallets/hour

Note: Technical data subject to variations without prior notice. Output depends on the type of pallet used.

The wrapping cycle starts and ends at the top of the pallet; this uniquely different approach to attaching and cutting the stretch-film provides the following advantages:

- Selectable top banding capability

- Stabilizes the load early in the wrap cycle

- Places the ending film tail at the top of the load instead of the bottom

- Eliminates the need of a film clamp power source on the turntable (therefore less maintenance; no need of compressed air with hook-ups or noisy compressors)

- Easier, faster and safer positioning of the load on the turntable (no clamp or other systems that can be damaged)MAIN FEATURES:

- Working functions and operations controlled by a PLC, with touch-screen Operator Interface

- Power Off / On – Reset switch and Power-On indicator light

- Single button Auto Wrap cycle Start/Pause

- Machine status visual indicator (run; clear or fault)

- Selection among three (3) different types of wrapping : automatic / semi-automatic / top banding

- Photo-eye for the automatic load height detection

- Separate setting of the top and bottom wraps, from 1 to 12 revolutions;

- Variable turntable speed control (adjustable from 3 to 15 rpm), with a soft start acceleration and a final revolution deceleration with positive stop alignment

- Film tension control

- Broken film/run-out of film detection with automatic machine reset

- Separate film carriage raise and lower speed controls

- Film carriage Lower/Raise buttons

- Film carriage with an adjustable speed motor and driving through a belt/pulley with Anti-Fall Device.

- Pre-stretch film carriage (max film width of 500 mm) with a 200% fixe ratio (1 mt = 3 mt), powered by a variable speed motor, with a fully electronic dynamic dancer corner compensation

- Carriage descent obstruction shut-off device for additional safety

- Side mounted film carriage for operator convenience and safety

- Turntable inserted in a square-shaped frame and supported by a 36 roller bearing system (direct chain driving system, with chain tensioner)

- Button for the manual control of the turntable rotation

- Predisposal for lifting the machine (with a fork lift) from the front and from the rear side (holes in the basement frame)

- Heavy duty frame with structural steel construction and Electro-static powder coated paint finish

- Emergency Stop Button

Machine manufactured according to CE rules.