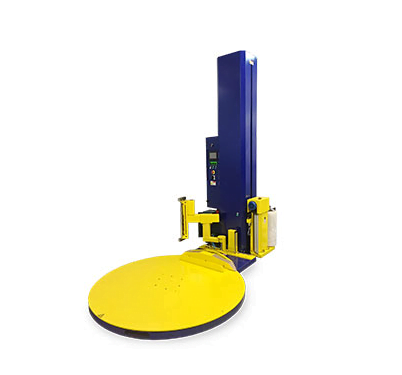

Italdibipack Ecospir Line

![]()

FULLY AUTOMATIC PALLET-WRAPPING LINES

Wide range of fully-automatic pallet-wrapping lines, from the simplest (infeed conveyor – pallet-wrapper – outfeed conveyor) up to the most complete and accessorized ones, both standardized or customized.

Machines manufactured according to CE rules

Italdibipack Ecospir Line

Overview

The Italdibipack Ecospir Line represents a comprehensive range of fully-automatic and semi-automatic pallet-wrapping machines designed to meet diverse packaging needs. These machines are engineered to provide efficient, reliable, and secure wrapping solutions for various industrial applications. With models ranging from basic infeed conveyor systems to complete wrapping lines, the Ecospir Line offers unparalleled flexibility and performance.

Key Features

- Versatile Configurations: Available in configurations from simple infeed conveyor systems to complete wrapping lines, catering to different operational requirements.

- High Wrapping Height: Models like the Ecospir TS EV offer a maximum wrapping height of 2200 mm, accommodating tall loads.

- Robust Turntable: Equipped with turntables of varying diameters, such as 1500 mm and 1650 mm, ensuring stability and efficient wrapping of loads.

- Heavy Load Capacity: Capable of handling loads up to 1200 kg, making it suitable for heavy-duty applications.

- Advanced Film Carriage: Features a film carriage with a 200% fixed ratio power pre-stretch, ensuring optimal film usage and cost efficiency.

- User-Friendly Interface: Operator control panels are equipped with touch screens for easy and intuitive operation, allowing for rapid setting and regulation of parameters.

- Customisable Wrapping Cycles: Offers the ability to set multiple wrapping cycles, each with personalised parameters, to meet specific packaging needs.

Technical Specifications

- Turntable Diameter: 1500 mm to 1650 mm, depending on the model.

- Maximum Wrapping Height: Up to 2700 mm with extended mast options.

- Load Capacity: Up to 1200 kg.

- Film Roll Dimensions: Compatible with standard stretch film rolls up to 500 mm in width.

- Machine Weight: Approximately 430 kg for models like the Ecospir TS EV.

- Power Supply: Standard models operate on 230 V – 1 Ph – 50 Hz.

Benefits

- Increased Efficiency: Fully-automatic operation and high wrapping speeds significantly enhance overall productivity.

- Cost Savings: Advanced film carriage technology ensures optimal film usage, reducing material costs.

- Flexibility: Wide range of configurations and customisable wrapping cycles make the Ecospir Line suitable for various packaging requirements.

- Ease of Use: User-friendly touch screen interfaces simplify operation and reduce the learning curve for new users.

- Durability: Robust construction and high-quality materials ensure long-lasting performance in demanding industrial environments.

Applications

The Italdibipack Ecospir Line is perfect for businesses looking to optimise their pallet-wrapping processes. It is particularly well-suited for:

- Manufacturing Plants: Ensuring secure and efficient wrapping of products for shipment.

- Warehouses: Streamlining the bundling and securing of goods.

- Distribution Centres: Facilitating quick and reliable wrapping of packages for distribution.

Conclusion

The Italdibipack Ecospir Line stands out as a reliable and efficient solution for automatic and semi-automatic pallet-wrapping needs. Its combination of advanced features, user-friendly design, and robust construction makes it an excellent choice for various industrial and commercial packaging applications. Invest in the Ecospir Line to enhance your packaging operations and ensure secure, efficient wrapping of your products.

Please feel free to contact us for more detailed information and to explore how the Ecospir Line can benefit your operations.

- Automatic pallet-wrapping equipped with top-pressing unit.

- Device integrated in the turntable and synchronized to transfer a pallet from a chain to a roller conveyor.

- Power pre-stretch system granting a film economy up to 70%.

- Main control box.

- Automatic top covering machine (on request antistatic unit to reduce electrostatic charges).

- Motorized chain conveyor system for pallet transfer.

- Motorized roller conveyor system for pallet transfer.

- Grilled fence for safety and protection.

Machine manufactured according to CE rules

LAYOUT OF A STANDARDIZED PALLET-WRAPPING LINE

TECHNICAL FEATURES OF A STANDARDIZED PALLET-WRAPPING LINE

Power supply 220/380 V – 3 Ph + N

Maximum pallet dimensions 800×1200 mm / 1000×1200 mm

Maximum pallet height 1800 mm

Maximum pallet weight 1200 kgs

Motorized chain conveyor speed 10 m/min.

Motorized roller conveyor speed 10 m/min.

Output 20/50 pallets/hour