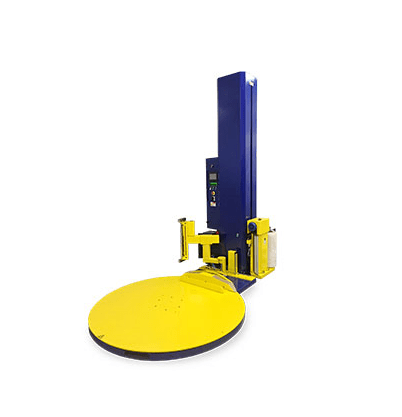

Italdibipack Ecospir FA

![]()

IDEAL WHEN THERE ARE LOTS OF PALLETS TO BE WRAPPED

This pallet-wrapper holds all the advantages of the various models of the Ecospir line, but in addition it doesn’t need the presence of an operator in loco to work as it is controlled through a remote control by the operator who can do something else in the meantime. The whole pallet-wrapping process, from film clamping up to film cutting at the end of the cycle , is automatic. Ideal to wrap a very high number of pallets.

Ecospir FA

Italdibipack Ecospir FA

Overview

The Italdibipack Ecospir FA is a fully automatic pallet-wrapping machine designed to handle high-volume packaging operations with ease and efficiency. This advanced machine automates the entire wrapping process, from film clamping to cutting and welding, ensuring consistent and secure wrapping of pallets. Ideal for businesses that require reliable and high-speed pallet wrapping, the Ecospir FA offers robust performance and user-friendly features.

Key Features

- Fully Automatic Operation: Automates the entire wrapping process, including film clamping, cutting, and welding, activated through a remote control.

- High Load Capacity: Capable of handling loads up to 2000 kg, making it suitable for heavy-duty applications.

- Automatic Height Detection: Utilises a photo-eye to automatically detect pallet height, ensuring precise and consistent wrapping.

- Cross Wrapping Cycle: Features a cross wrapping cycle during the film carriage ascent and descent, with adjustable wrapping at the base and top of the load.

- Adjustable Turntable Speed: Turntable speed is adjustable up to 12 rpm, controlled by an inverter for smooth operation.

- Film Pre-Stretch System: Equipped with a motorised pre-stretch system with a fixed ratio of 200%, optimising film usage and reducing costs.

- Low Profile Turntable: The turntable has a low profile of 75 mm from the floor level, facilitating easy loading and unloading of pallets.

Technical Specifications

- Power Supply: 240 V – 50 Hz – Single Phase

- Power Required: 1.25 kW

- Turntable Diameter: 1650 mm

- Maximum Load Capacity: 2000 kg

- Maximum Wrapping Height: Adjustable up to 2200 mm

- Film Roll Dimensions: Compatible with stretch film rolls up to 500 mm in width, with a maximum external diameter of 250 mm and a core diameter of 76 mm (3 inches)

- Machine Dimensions (L x W x H): 2700 mm x 1650 mm

- Machine Weight: Approximately 700 kg

- Air Consumption: 10 Nl/cycle at 6 bar

- Noise Level: Below 75 dB

Benefits

- Increased Productivity: Fully automatic operation and high-speed wrapping capabilities significantly enhance overall productivity.

- Cost Efficiency: The film pre-stretch system ensures optimal film usage, reducing material costs.

- Consistency and Reliability: Automatic height detection and cross wrapping cycle ensure uniform and secure wrapping of pallets.

- Ease of Use: Remote control activation and user-friendly interface simplify operation, reducing the learning curve for new users.

- Durability: Robust construction and high-quality materials ensure long-lasting performance in demanding industrial environments.

Applications

The Italdibipack Ecospir FA is perfect for businesses looking to optimise their pallet-wrapping processes. It is particularly well-suited for:

- Manufacturing Plants: Ensuring secure and efficient wrapping of products for shipment.

- Warehouses: Streamlining the bundling and securing of goods.

- Distribution Centres: Facilitating quick and reliable wrapping of packages for distribution.

Conclusion

The Italdibipack Ecospir FA stands out as a reliable and efficient solution for fully automatic pallet-wrapping needs. Its combination of advanced features, user-friendly design, and robust construction makes it an excellent choice for various industrial and commercial packaging applications. Invest in the Ecospir FA to enhance your packaging operations and ensure secure, efficient wrapping of your products.

Please feel free to contact us for more detailed information and to explore how the Ecospir FA can benefit your operations.

- Power supply: 240 V – 1 Ph – 50 Hz + T + 1,25 kw

- Power required: 1,5 KW

- Overall machine dimensions: 2800 mm L x 1650 mm W

- Turn-table height above floor: 75 mm

- Machine Weight: 700 kg

- Turn-table diameter: 1650 mm

- Maximum pallet dimensions: 1000 x 1200 mm

- Maximum pallet height: 2700 mm

- Maximum pallet weight: 2000 kg

- Maximum roll diameter: 300 mm

- Roll height: 500 mm

- Compressed air: 10 Nl – 6 bar

- Turn-table speed: Up to 12 cycles/min

Notes: Technical data subject to variations without prior notice

Output depends on the type of pallet to be wrapped

- Fully automatic working process activated through a remote control: automatic film clamping at the beginning and automatic film cutting/welding at the end of the cycle

- Cross wrapping cycle (during the film carriage ascent and descent) with adjustable setting for the bottom and top reinforcing wraps

- Low profile turntable (75 mm from the floor level, with chain transmission), 1650 mm diameter, suitable for pallets with a dimensions up to 1000 mm x 1200 mm

- Turntable (chain transmission) rotating speed up to 12 rpm, controlled by inverter, with soft star and progressive indexed arrival at the end of the cycle in the same starting position

- Automatic pallet height detection through photo-eye ( black, white or reflecting loads require specific photo-eyes that can be mounted on request)

- Film carriage (chain transmission with adjustable speed, controlled by inverter) equipped with a 200% fixed power pre-stretch system ( 1 mt = 3 m) with an easy film loading and tension control

- Stretch-film roll with external diameter up to 250 mm, on a 32 (76 m) internal core, and width/height of 500 mm (thickness up to 35 my)

- Working functions controlled through by microprocessor

- Noise level: less than 75 dB (without film)

- Suitable to operate in room conditions with temperature between +5 °C and +40 °C (humidity less than 95%)