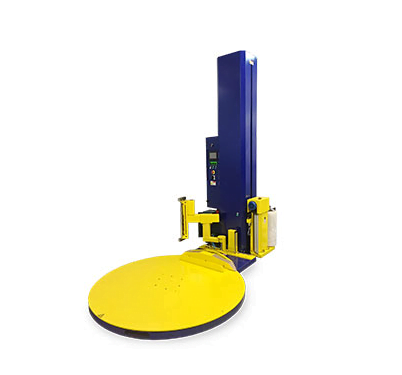

Italdibipack Ecospir EV

![]()

ITALDIBIPACK is proud to announce ECOSPIR EV, a very interesting news in its range of pallet wrapping machines with the target to make its offer even more competitive in terms of quality, performances, flexibility .. and price!

The ECOSPIR ELC/S-X and ECOSPIR IDX is nowadays substituted by one machine, the ECOSPIR EV, available in several different versions and executions.

Ecospir EV

Italdibipack Ecospir EV

Overview

The Italdibipack Ecospir EV is a robust semi-automatic pallet wrapping machine designed for efficient and reliable packaging operations. With its open turntable design and user-friendly interface, this machine streamlines the wrapping process for various industrial applications.

Key Features

- Touch Screen Control Panel: Intuitive interface for quick setting and regulation of parameters.

- Customisable Programs: Ability to store up to 8 different wrapping programs.

- Adjustable Turntable Speed: Controlled through an inverter with soft start and progressive arrival at the starting position.

- Film Tension Control: Regulation through a mechanical brake system.

- Adjustable Film Carriage Speed: Controlled by inverter with separate parameters for ascent and descent.

- Reinforcing Wraps: Separate settings for bottom and top reinforcing wraps.

- Flexible Operation: Option for manual or automatic working procedures for each preset program.

Technical Specifications

- Turntable Diameter: 1500 mm (standard), 1650 mm (optional)

- Maximum Load Capacity: 2000 kg

- Maximum Wrapping Height: 2200 mm (standard), 2700 mm (optional extended mast)

- Power Supply: 240 V – 50 Hz – Single Phase

- Power Required: 1 KW

- Machine Dimensions: Approximately 1500 x 2440 x 2550 mm (L x W x H)

- Machine Weight: 430 kg

Benefits

- Increased Efficiency: Semi-automatic operation streamlines the wrapping process.

- Versatility: Suitable for various pallet sizes and load types.

- User-Friendly: Intuitive touch screen interface reduces operator training time.

- Customisation: Multiple preset programs allow for tailored wrapping solutions.

- Durability: Robust construction ensures long-lasting performance in industrial environments.

Optional Features

- Extended mast for 2700 mm wrapping height

- Film carriage with 200% fixed ratio power pre-stretch

- Weighing scale system with display and printer

- Ramp for pallet truck and electric ant

Conclusion

The Italdibipack Ecospir EV is a versatile and efficient semi-automatic pallet wrapper suitable for various industrial packaging needs. Its combination of user-friendly features, customisable settings, and robust construction make it an excellent choice for businesses looking to optimise their packaging operations.

Please feel free to contact us for more detailed information and to explore how the Ecospir EV can benefit your operations.

- Turntable diameter: 1500 mm

- Maximum weight of the load: 2000 kg

- Maximal wrapping height: 2200 mm

- Power required: 1 kW @ 240 V 1 ph + T

Notes: Technical data subject to variations without prior notice

Output depends on the type of pallet to be wrapped

- Regulation of the turntable rotating speed controlled through inverte, with soft start and progressive arrival in the same starting position

- Turntable transmission by chain

- Turntable motor protected with a carter

- Regulationof the film tnsion through mechanic brake

- Regulation of the film carriage speed, controlled through inverter and with separate parameters for the ascent and descent

- Film carriage driving motor integrated in the mast (column)

- Film carriage transmission by chain

- Separate setting for the botton and top reinforcing wraps

- Possibility to set a number wrappiing cycles, each of them with all the parameters personalised by the operator

- Manual or automatic working procedure for each af the pre-set programmes

- Operator control panel type “touch screen” with a very easy, simple and intuitive use, for a rapid setting and regulation of all the different paramenters

- Hinge facility (column/basement) for an easy and fast assembling of the unit

- Basament with front predisposal for being lifted and moved with a fork-lif

ACCESSORIES AND OPTIONS AVAILABLE ON REQUEST

- Turntable with a 1650 mm diameters

- Extended mast for a wrapping height of 2700 mm

- Film carriage with a 200% fixed ratio (1mt = 3mt) power pre-stretch, with direct transmission through gear and separate regulation of the film tension from the control panel

- Weigh scale system, complete with a visual display and printe for normal and/or adhesive paper