Italdibipack Dibiflow Line

![]()

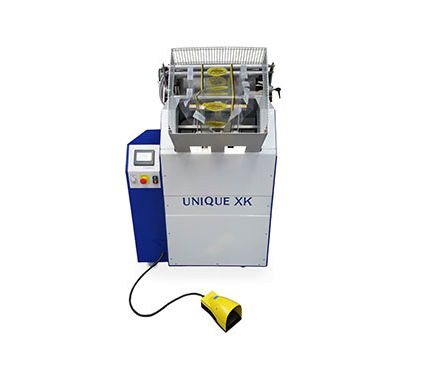

Dibiflow Line is the horizontal automatic packaging machines line with high quality features and manufacturing standards. Easy to use, high versatility and fast production change. Wide range of additional accessories. DIBIFLOW LINE is available in different versions depending on the product size.

Dibiflow Line

Italdibipack Dibiflow Line

Overview

The Italdibipack Dibiflow Line is a series of high-performance horizontal automatic packaging machines designed to meet the diverse needs of various industries. Known for their high quality, versatility, and ease of use, these machines are ideal for packaging a wide range of products, including food items, confectionery, ice cream, cosmetics, pharmaceuticals, and technical items. The Dibiflow Line combines advanced technology with user-friendly features, making it a valuable addition to any production line.

Key Features

- High Versatility: Capable of storing up to 99 different working programs with personalised parameters, allowing for quick and easy product changes.

- User-Friendly Interface: Equipped with a 3” colour touch screen panel for easy use and fast regulation of different parameters.

- Advanced Motorisation: Features a driving group with three independent brushless motors for the in-feed chain conveyor belt, film pulling wheels, and jaws rotation.

- Robust Construction: Parts in contact with the product are made of stainless steel, ensuring durability and compliance with hygiene standards.

- Customisable Options: Wide range of additional accessories available on request, including motorised outfeed belts, printers for expiry dates/product codes, photocells for registered print films, and more.

Technical Specifications

Dibiflow 300

- Power Supply: 220V single-phase voltage 50Hz

- Output: 80-100 pieces per minute

- Max Film Roll Width: 300 mm

- Film Holder Group: Film holder shaft with centering cones and axial regulation of the film roll

- Film-Driving Wheels: Double set of longitudinal welding wheels (heated for film sealing and cold for film driving)

- Transversal Jaws Group: Single-transversal cross jaw with welding design parallel to the bag width, straight cut, jaw width of 170 mm

- Machine Dimensions: Compact design suitable for various industrial settings

Dibiflow 500

- Power Supply: 240 V – 1 Ph – 50/60 Hz

- Driving Group: In-feed conveyor belt, film pulling wheels, jaws rotation, independent motorisation of the exit belt

- Product Feeding Group: Lateral adjustable guides, stainless steel AISI 304 parts, lugged loading belt (1600 mm standard), pushing lugs in food-grade plastic

- Film Holder Group: Predisposed for mounting a photocell for printed films, cantilevered structure in aluminium and painted steel, reel holder with expanding shaft

- Film-Driving Wheels: Two sets of wheels for longitudinal sealing

- Jaws Group: Electronic safety clutch on the transversal welders

Benefits

- Increased Efficiency: High-speed operation and the ability to store multiple working programs significantly enhance overall productivity.

- Consistency: Ensures uniform and professional packaging for all products with precise sealing control.

- Versatility: Suitable for a wide range of products, offering flexibility in packaging operations.

- Space Optimisation: Despite their high capacity, the machines have a relatively compact footprint for their capabilities.

- Cost-Effective: High-speed operation and minimal operator requirements lead to reduced per-unit packaging costs.

Applications

The Italdibipack Dibiflow Line is perfect for businesses in various sectors, including:

- Food Industry: Packaging of confectionery, ice cream, and other food items.

- Pharmaceuticals: Efficient wrapping of pharmaceutical products.

- Cosmetics: Packaging of cosmetic products.

- Technical Items: Suitable for wrapping technical components, spare parts, and various kits.

Conclusion

The Italdibipack Dibiflow Line stands out as a reliable and highly efficient solution for horizontal automatic packaging needs. Its combination of advanced features, user-friendly design, and robust construction makes it an excellent choice for businesses looking to optimise their packaging operations. Invest in the Dibiflow Line to significantly enhance your packaging productivity and ensure consistent, high-quality wrapping of your products.

Please feel free to contact us for more detailed information and to explore how the Dibiflow Line can benefit your operations.

- Ergonomic position of the different controls position

- Machine shutdown in phase with open welders

- Control panel with: start button – tension light – reset button – emergency button – stop button in phase – key selector for continuous or impulse operation

- Control panel from 5″ to 7″ ( touch-screen type), with colour display, with the possibility to set and recall: machine speed – pack length – temperatures – product phase – possibility to memorize up to 99 programs

- Installed power: from 3 KW to 6 KW

- Voltage: 400V three-phase + T + N

- Compressed air consumption: 50 NL at 6/7 atmospheres (Dibiflow 600 and 700)

- Output: from 50 to 100 pc/min

- On request, It is possible to supply machines with roll in bottom position

Dibiflow Line is characterized by high quality features and manufacturing standards: easy to use, fast production change, high versatility, possibility to store up to 99 different working programs with personalized parameters, operator touch screen panel for the easy use and fast regukation of the different parameters. Wide range of additional accessories.

Dibiflow Line specifications:

A Driving Group:

- In-feed conveyor belt (400W brushless motor)

- Film pulling wheels (400W brushless motor)

- Jaws rotation (400W brushless motor)

- Independent motorization of the exit belt

Product Feeding Group:

- Lateral adjustable guides

- Parts in contact with the product in stainless steel AISI 304

- Lugged loading belt, length 1600 mm (standard)

- Pushing lugs with rapid extraction in plastic material suitable for contact with foodstuffs

- Tunnel/film conformer adjustable type (on request also available the fix type)

Film Holder Group:

- Predisposal for the mounting of the photocell for the detection of the mark on printed films

- Cantilevered structure in aluminum and painted steel (RAL 7035 GREY – RAL 5002 BLUE) and stainless steel casing

- Reel holder with expanding shaft

Fil – Driving Wheels:

- Two sets of wheels for longitudinal sealing (Dibiflow 500)

Jaws Group:

- Three sets wheels for longitudinal sealing (Dibiflow 600 and 700)

- Electronic safety clutch on the transversal welders

OPTIONS:

- Printer for expiration date and lot production

- Film spot photo-eye

- Adjustable conformers

- Double transversal jaws

- Zig-zag for easy opening of the bag

- Horizontal cross cut

- Automatic infeeder

- Predisposal for the synchronization of a printer with machine, through touch-screen

- Infeed belt with extended length of one meter

- Film perforating unit to reduce the amount of air inside the package

- Exit belt of about 800 mm in long

- Possibility of machine with reel holder in lower position for upper welding