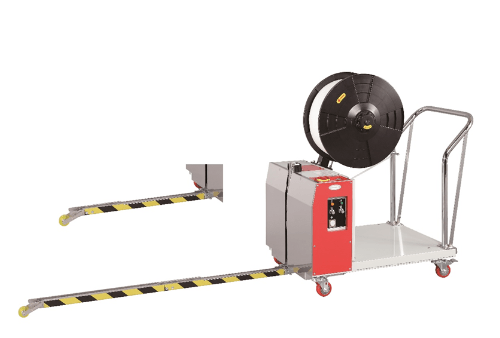

Italdibipack Deltareg AA500

![]()

HIGH SPEED AUTOMATIC STRAPPING

High speed automatic strapping arch machine equipped with inclinable steel working-plate to lay the package, with automatic strapping operated by a pedal, button or photo-eye on the working-plate.

Italdibipack Deltareg AA500

Overview

The Italdibipack Deltareg AA500 is a high-speed automatic strapping arch machine designed to streamline end-of-line packaging processes. This advanced machine is equipped with an inclinable steel working plate and offers automatic strapping operated by a pedal, making it an ideal choice for high-volume packaging environments.

Key Features

- High-Speed Operation: Designed for rapid strapping, the Deltareg AA500 significantly boosts packaging efficiency.

- Automatic Strapping: Operated via a pedal, ensuring quick and easy use.

- Steel Standard Arch: Features a robust 700 x 500 mm steel arch for reliable performance.

- Electronic Control Board: Provides precise control over the strapping process.

- Instant Sealing: Utilises a warmed wire for immediate and secure sealing.

- External Strap Tension Adjustment: Allows for easy and precise adjustment of strap tension.

- Adjustable Working Plate Height: The height can be adjusted between 850 and 930 mm to suit various operational needs.

- Mobility: The machine is equipped with wheels, enabling quick relocation and flexible use across different tasks.

- Automatic Roll Change: Automatically stops and changes the roll when it is depleted, reducing downtime.

Technical Specifications

- Arch Size: 700 x 500 mm

- Strap Types: Compatible with PET, PPL, and metallic straps

- Control Panel: 24V electric control panel located on the operator side

- Power Supply: 240 V – 1 Ph – 50 Hz

- Installed Power: 1 KW

- Dimensions (L x W x H): 940 x [dimension not provided]

- CE Compliance: Manufactured according to CE standards

Benefits

- Enhanced Productivity: The high-speed operation and automatic features significantly reduce the time required for strapping, enhancing overall productivity.

- User-Friendly: The electronic control board and pedal operation make the machine easy to use, even for operators with minimal training.

- Durability and Reliability: The steel arch and robust construction ensure long-lasting performance and reliability.

- Flexibility: Adjustable working plate height and external strap tension adjustment cater to various packaging requirements.

- Reduced Downtime: Automatic roll change feature ensures continuous operation without frequent interruptions.

Applications

The Italdibipack Deltareg AA500 is perfect for businesses seeking to optimise their packaging processes. It is particularly well-suited for:

- Manufacturing Plants: Ensuring secure and efficient packaging of products for shipment.

- Warehouses: Streamlining the bundling and securing of goods.

- Distribution Centres: Facilitating quick and reliable strapping of packages for distribution.

Conclusion

The Italdibipack Deltareg AA500 is a top-tier solution for high-speed automatic strapping needs. Its combination of advanced features, user-friendly design, and robust construction makes it an excellent choice for various industrial and commercial packaging applications. Invest in the Deltareg AA500 to enhance your packaging operations and ensure secure, efficient strapping of your products.

Please feel free to contact us for more detailed information and to explore how the Deltareg AA500 can benefit your operations.

- Power supply: 230 V – 1 Ph – 50 Hz

- Power required: 0,7 KW

- Overall machine dimensions L x W x H: 940 x 640 x 1470 mm

- Working-plate height: 850 ÷ 930 mm

- Machine weight: 125 kg

- Strap tension: 1,5 ÷ 40 kg

- Strap width: 5 – 9 mm

- Internal roll diameter: 200 – 280 mm

- Minimum product dimensions W x H: 100 x 30 mm

- Output: 50pcs/min

Notes: Technical data subject to variations without prior notice

Output depends on the operator and the type of the package

- Steel standard arch 700 x 500 mm

- Electronic Control Board

- Automatic reset operated by a pedal

- 24V electric control panel

- Control panel located on the operator-side

- Instant sealing through a warmed wire

- External adjustment of strap tension

- Soft adjustment of strap tension on the control panel

- Working-plate height adjustable (850 ÷ 930 mm)

- Automatic roll change and stop when roll is ended

- Machines are on wheels so they may be moved quickly from one task to another

- The machine works with PET and PPL or metallic strap.

Machine made according to CE rules.