Hugo Beck Suction Belt/Mailtables

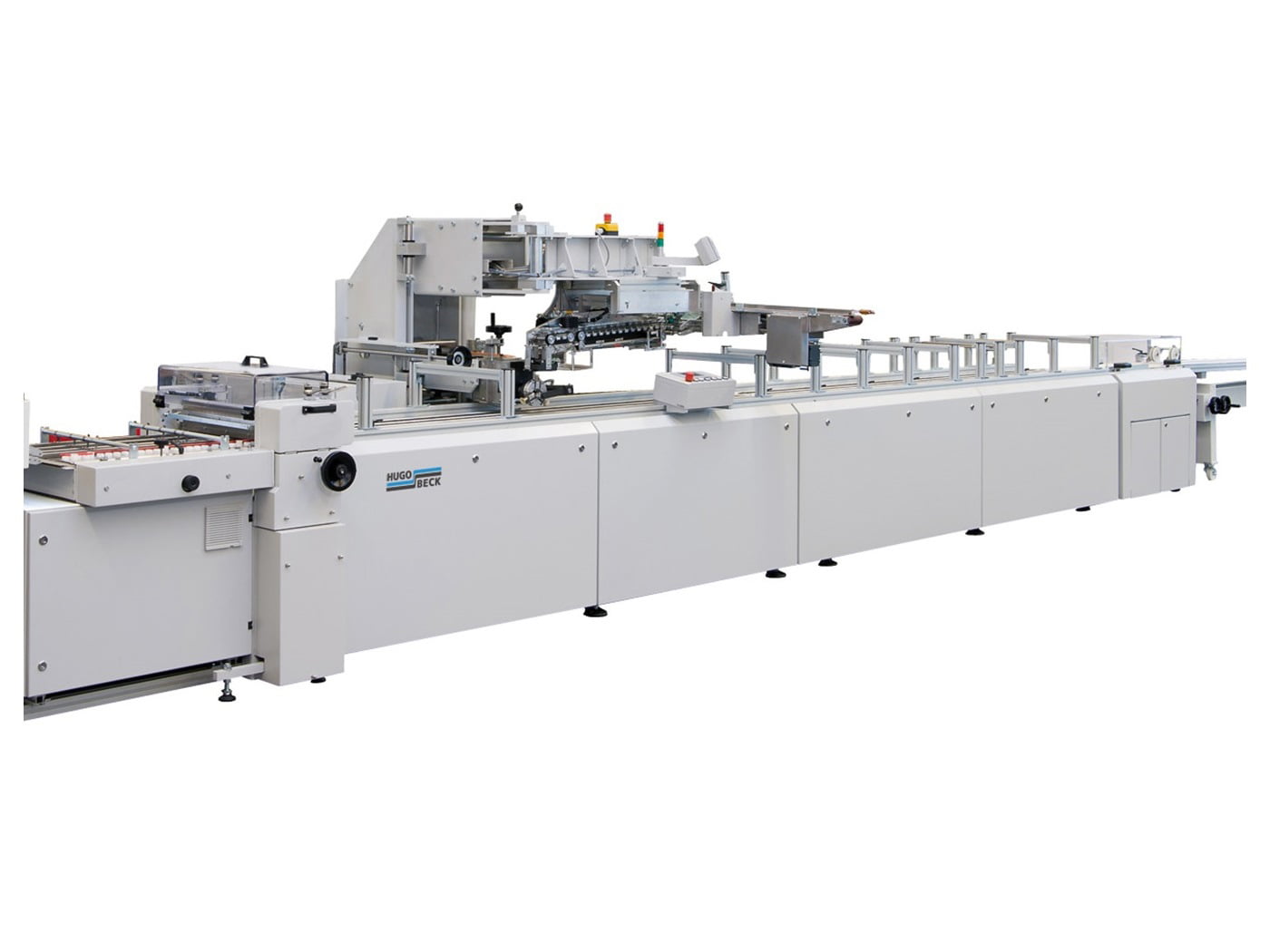

Hugo Becks’s high-performance, flexible positionable mailtables are called “maillines” and usually consist of a feeder and an attached alignment section with an outfeed suction belt. All feeders can be used flexibly within the mailline.

The maillines are primarily used for processing flyers, which are for example fed in, grooved and then glued and personalised.

In addition to the mailline they offer the mailline advance, which is not equipped with a continuous suction belt, but with four or six suction conveyor belts, which can be freely shifted and adjusted. The products to be packaged are folded, ploughed or glued.

Mailline suction belt with labeling head

Mailline suction belt and addressing

Hugo Beck Suction Belt/Mailtables

Overview

The Hugo Beck Suction Belt/Mailtables are high-performance, flexible systems designed for efficient mail processing and packaging. These systems, known as “maillines,” typically consist of a feeder and an attached alignment section with an outfeed suction belt. They are primarily used for processing flyers, which can be fed in, grooved, glued, and personalised.

Key Features

- High Performance: Designed to handle high volumes of mail processing efficiently.

- Flexible Positioning: The mailtables are freely positionable, allowing for easy integration into various production environments.

- Integrated Systems: Usually consist of a feeder and an alignment section with an outfeed suction belt, ensuring smooth and precise handling of materials.

- Versatile Applications: Suitable for processing a wide range of printed materials, including flyers, brochures, and other mail items.

- Customisation: Can be tailored to meet specific customer requirements, ensuring optimal performance for diverse applications.

Technical Specifications

- Components: Typically include a feeder, alignment section, and outfeed suction belt.

- Material Handling: Capable of processing various types of printed materials, including flyers and brochures.

- Integration: Can be integrated with other Hugo Beck systems and third-party devices, thanks to their flexible positioning and independent control units.

Benefits

- Efficiency: High-speed processing ensures that large volumes of mail items can be handled quickly and efficiently.

- Precision: The alignment section and suction belt ensure accurate handling and processing of materials, reducing errors and improving quality.

- Flexibility: Freely positionable design allows for easy integration into existing production lines and adaptability to different processing needs.

- Customisation: Tailored solutions ensure that the system meets specific customer requirements, enhancing overall performance and efficiency.

Applications

The Hugo Beck Suction Belt/Mailtables are ideal for businesses in various sectors, including:

- Print and Multimedia: Processing and packaging printed materials such as flyers, brochures, and catalogues.

- Mail Order and E-Commerce: Efficient handling and packaging of mail items for distribution.

- Advertising and Marketing: Personalising and packaging promotional materials for targeted marketing campaigns.

Conclusion

The Hugo Beck Suction Belt/Mailtables offer a highly efficient and flexible solution for mail processing and packaging needs. Their combination of high performance, precision, and customisation makes them an excellent choice for businesses looking to enhance their mail handling operations. Invest in Hugo Beck’s maillines to improve your processing efficiency and ensure high-quality handling of your printed materials.

For more detailed information and to explore how Hugo Beck Suction Belt/Mailtables can benefit your operations, please feel free to contact us.

| Product Size | from DIN A7 to DIN A3 |

| Capacity mailline and mailline advance | up to 25.000 cycles/hour |

| Capacity Feeders | up to 40.000 cycles/hour |