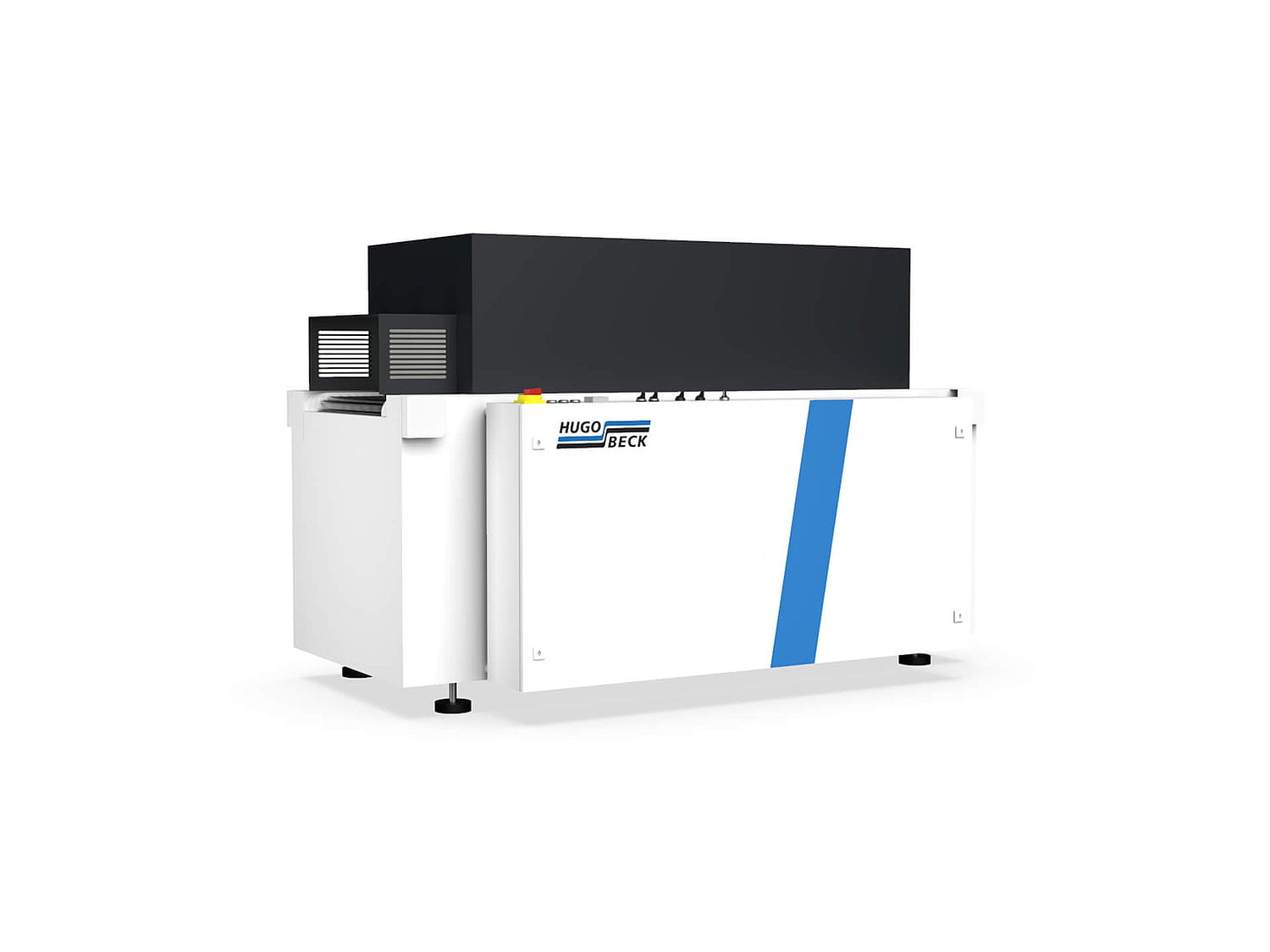

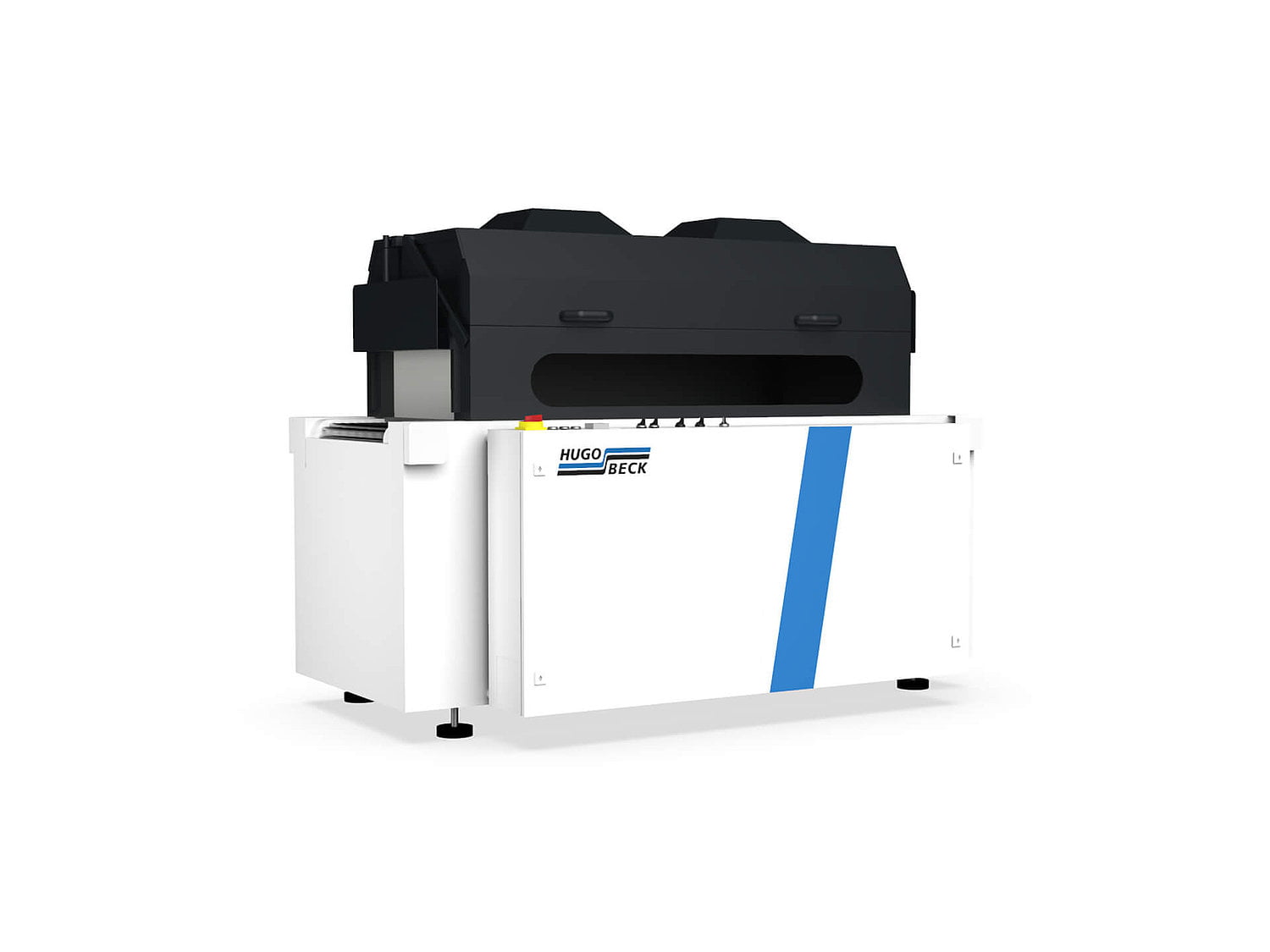

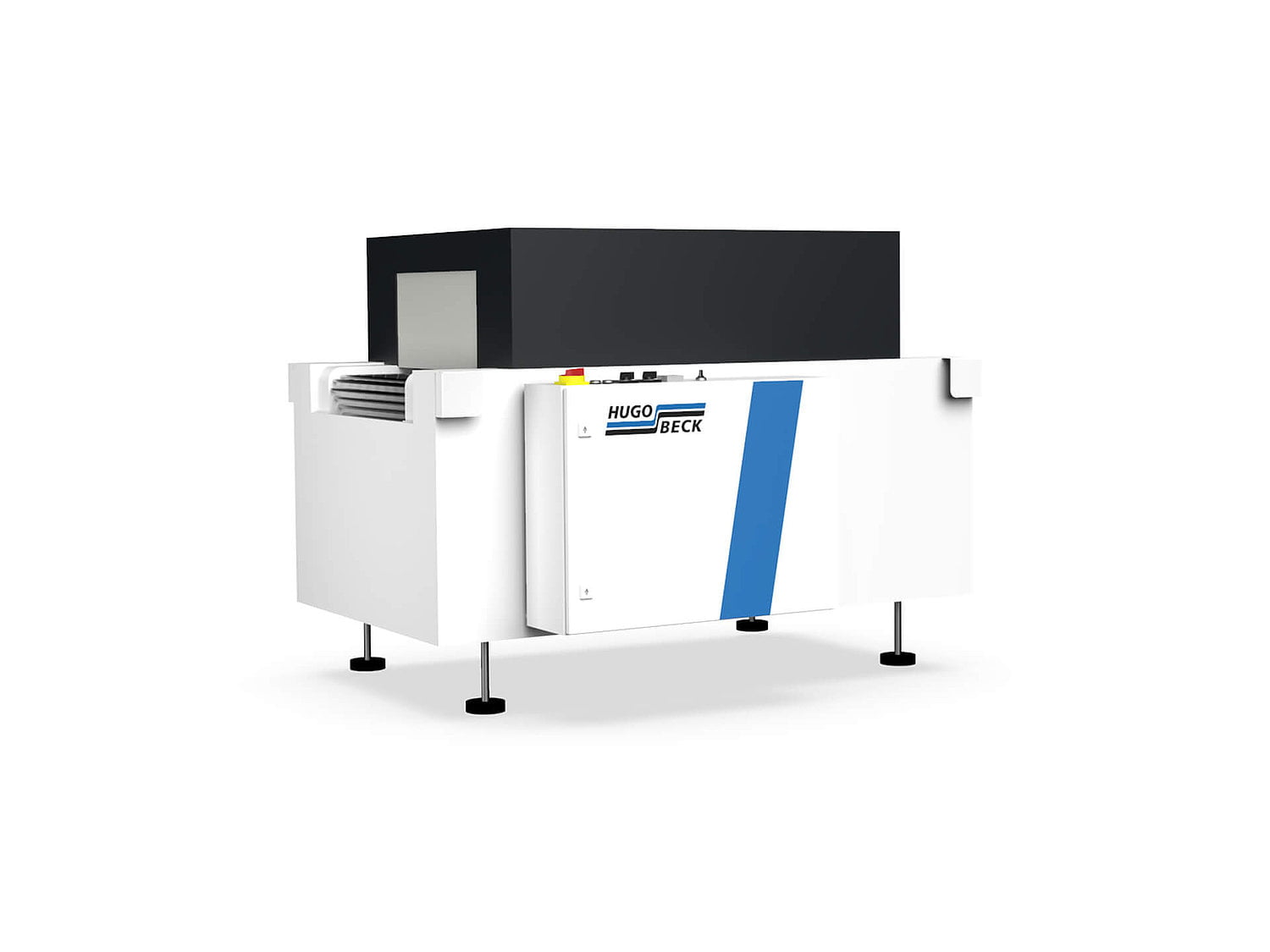

Hugo Beck Shrink Tunnels

AS EFFICIENT AND FLEXIBLE AS OUR PACKAGING MACHINES

Items that have initially been bagged using a machine from Hugo Beck often need to be shrunk so as to ensure a tight-fitting film and the perfect packaging finish to meet the highest standards.

Adapted for each packaging system, they supply the appropriate shrink tunnel in all sizes and performance ranges for the production of high-quality shrink packaging.

As such, they manufacture shrink tunnels in a number of versions, with a variety of rods and chains that operate like a link mesh belt. Textile mesh belts are also possible for very light products. In each case, the length of the shrink tunnel depends on the speed of packaging and on the film material selected.

State-of-the-art air ducting and heat recovery ensure efficient energy use, helping us to contribute to both protection of the environment and reducing energy costs.

The decision on whether to use a shrink tunnel with circulating air or convection principle is defined depending on the individual product application of the customer.

Hugo Beck Shrink Tunnels

Overview

Hugo Beck Shrink Tunnels are designed to complement any packaging system, providing high-quality shrink packaging for a variety of products. These tunnels are available in multiple sizes and performance ranges, ensuring they meet the specific requirements of different industries and applications.

Key Features

- Customisable Sizes: Available in a range of sizes to fit different packaging systems and product dimensions.

- Versatile Performance: Suitable for high-speed packaging lines, with various performance ranges to match production needs.

- Advanced Air Ducting: State-of-the-art air ducting and heat recovery systems ensure efficient energy use.

- Multiple Heating Options: Options for shrink tunnels with circulating air or convection principles, depending on the product application.

- High Thermal Efficiency: Designed for optimal shrink results with minimal energy consumption.

Technical Specifications

- Tunnel Length: Ranges from 1.20 meters to 5.5 meters.

- Tunnel Width: Ranges from 0.5 meters to 1 meter.

- Heating Methods: Available with circulating air or convection heating principles.

- Energy Efficiency: Features efficient energy use through advanced air ducting and heat recovery systems.

Benefits

- Efficiency: High air flow and low energy consumption ensure optimal performance.

- Flexibility: Adaptable to various packaging systems and product types.

- Precision: Provides a tight-fitting film for a perfect packaging finish.

- Sustainability: Contributes to environmental protection by reducing energy costs and improving energy efficiency.

Applications

Hugo Beck Shrink Tunnels are suitable for a wide range of sectors, including:

- Food and Beverage: Ensures hygienic and airtight packaging for food products.

- Pharmaceutical and Medical Technology: Provides hermetically sealed packaging to meet strict industry regulations.

- E-Commerce and Logistics: Enhances packaging for mail order and shipping operations.

- Consumer Goods: Ideal for packaging household items, personal care products, and other consumer goods.

Conclusion

Hugo Beck Shrink Tunnels offer a reliable and efficient solution for high-quality shrink packaging. With their customisable sizes, advanced heating options, and energy-efficient design, these tunnels are an excellent choice for businesses looking to improve their packaging processes. Invest in Hugo Beck Shrink Tunnels to achieve superior packaging results and enhance your production efficiency.

Please feel free to contact us for more detailed information and to explore how Shrink Tunnels can benefit your operations.

| Tunnel-Length | 1,20 m – 5,5 m |

| Tunnel-Width | 0,5 m – 1 m |

SIDE SEAL

Side sealing machines with film waste rewinders pack products with a lateral cut seal. As an option, machines can include a non-stop film waste disposal in production. Many different products can be bagged with Hugo Beck’s form fill and seal machines. Bags can be completely shrunk or simply sealed at the sides. No exchange parts are required to cope with different product sizes.

The lateral cut seal guarantees a high-quality pack finish without any film remaining on the product. Thanks to our patented tight packaging only as much film is used as is truly needed! This not only guarantees an unrivalled and outstanding finish to the film packaging, depending on the machine type, a film saving of up to 15% is also delivered.

The “side seal” packaging style can be produced at performance speeds of up to 80m/min.

Hugo Beck packaging machines process all types of machine-compatible films at maximum speeds including those that are considered problematic, for example due to their sealing ability, such as extremely thin packaging films available from just 7μm (e. g. polyolefin), 100% recyclable films made from monomaterials (e. g. polypropylene) and those made from recycled materials and bioplastics (e. g. PLA films).

BOTTOM CUT SEAL

This packaging style uses a cut seal underneath the product and, if required, high-quality shrink packaging is also possible. This is particularly suitable for packing round products with film. As an example, shrink packs of aerosol cans for the cosmetics industry can easily be produced.

A fixed or adjustable forming shoulder is available to form the film sleeve.

This packaging style can be produced at performance speeds of up to 50 m/min.

BOTTOM OVERLAP THERMO SEAL/STATIC SEAL

This overlap seal is applied in the middle of the product below. Hugo Beck uses the technology of seal welding or ionisation (with shrinking). This allows the overlap to be set centrally or laterally.

With fixed or adjustable forming shoulders, the film sleeve is optimally produced.

Speeds of up to 80 m/min are achievable with a bottom overlap and there is no film waste.

OVERLAP ON TOP

With this flexible overlap sealing, products can be closed at the top, centre or side. This shrink-wrapping technology is the perfect choice for the packaging of mailing products such as magazines or catalogues.

Instead of sealing, the products can also be wrapped in film with hot glue.

Film packaging with an overlap on top is available at production speeds up to 80 m/min.