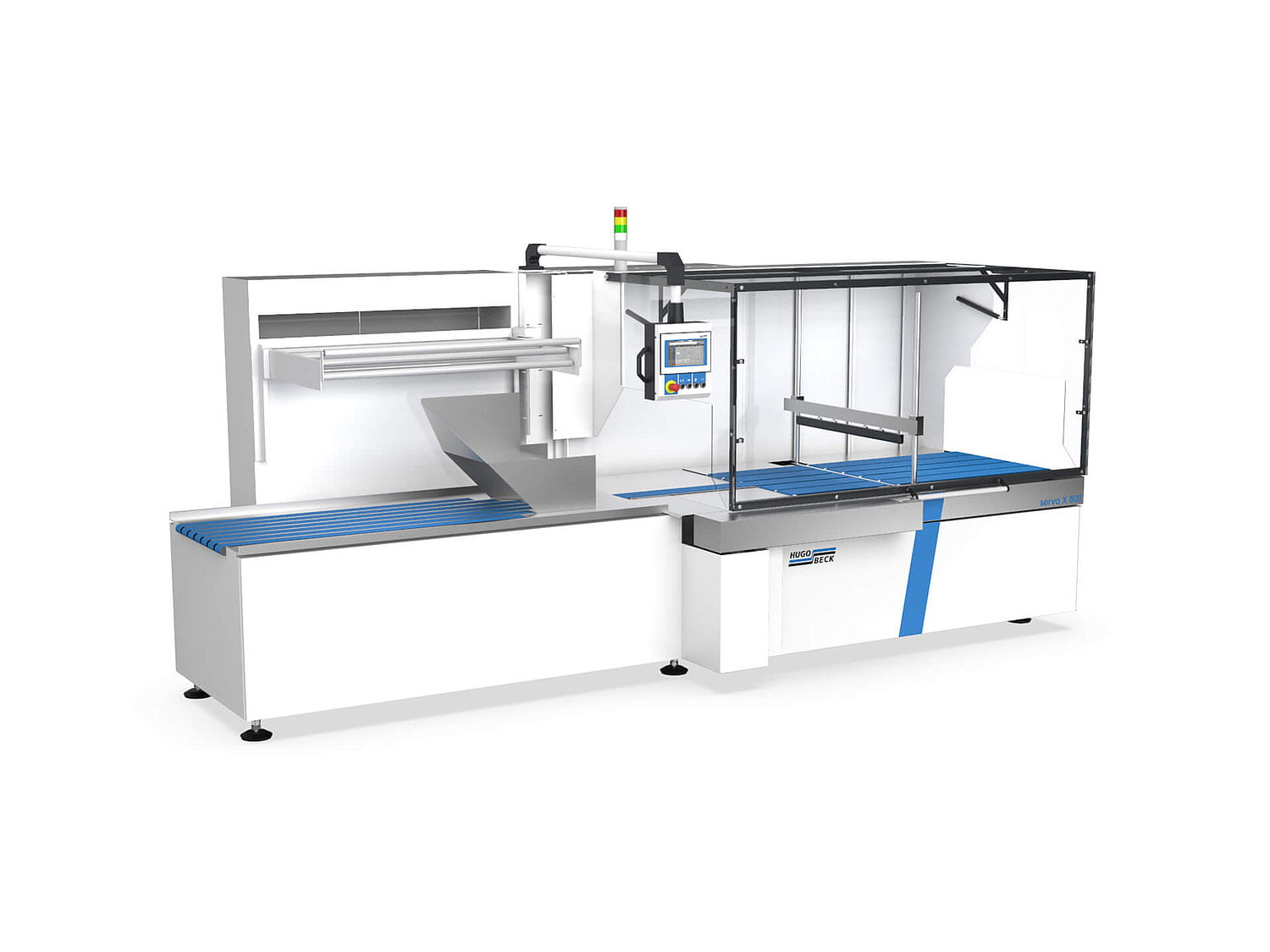

Hugo Beck Servo X 800

THE MODULAR HIGH-END ALLROUNDER FOR LARGE-FORMAT PRODUCTS.

The servo X 800 is the most flexible and powerful of film packaging machine in the horizontal large-format segment – and all this with maximum modularity.

It can be configured individually and thus meet all requirements.

Whether chain infeed or infeed conveyor, servo X 800 machines win over with their continuous packaging process and no stop-and-go, meaning dead time is not an issue when sealing. Besides high performance, this enables extremely tight-fitting and precise packaging with a saving in film of up to 15 %. This ensures that the film packaging‘s excellent appearance is unrivalled.

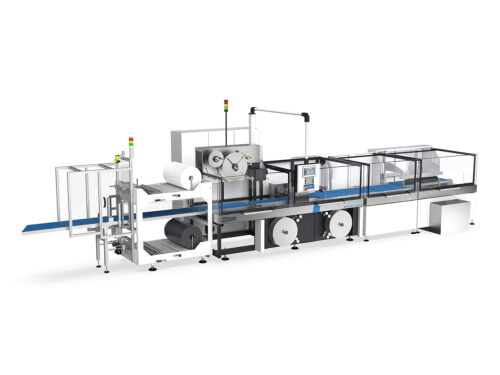

Producing individual, double and six packs of tissue rolls

Three different types of tissue roll shrink packs are easily produced on one single film packaging machine: Hugo Beck servo X 800.

Producing shrink packs of single tissue rolls or in groups

Film packaging of calendars with hang tag

Hugo Beck Servo X 800

Overview

The Hugo Beck Servo X 800 is a high-performance form fill and seal machine designed for large-format film packaging applications. This machine is renowned for its flexibility, precision, and efficiency, making it ideal for various industries that require robust and reliable packaging solutions.

Key Features

- High Performance: Capable of up to 5,000 cycles per hour, ensuring maximum productivity.

- Modularity: Highly modular design allows for individual configuration to meet specific packaging requirements.

- Continuous Packaging Process: Operates without stop-and-go, eliminating dead time during sealing and ensuring a smooth, efficient process.

- Tight-Fitting Packaging: Provides extremely tight-fitting and precise packaging, with a film saving of up to 15%.

- Versatile Film Handling: Processes a wide range of film types, including PE, PO, PP, bio films, and recycled content films.

Technical Specifications

- Product Infeed: Manual as standalone or automatic in line.

- Film Types: Centre-folded and flat film, such as PE, PO, PP, bio films, and recycled content films.

- Product Size: Length from 150 mm.

- Capacity: Up to 5,000 cycles per hour.

- Versions: Available with side seal, bottom overlap with or without sealing/ionisation.

Benefits

- Efficiency: High-speed operation and continuous packaging process significantly boost productivity and reduce downtime.

- Flexibility: Modular design and versatile film handling capabilities make it adaptable to various product sizes and packaging requirements.

- Precision: Ensures consistent, high-quality packaging with minimal material waste.

- Sustainability: Supports the use of recyclable and eco-friendly film materials, reducing environmental impact.

Applications

The Hugo Beck Servo X 800 is suitable for a variety of sectors, including:

- Food and Beverage: Ideal for packaging large-format food items, ensuring airtight and hygienic packaging.

- Pharmaceutical and Medical Technology: Provides hermetically sealed packaging for medical products and devices.

- E-Commerce and Logistics: Enhances packaging processes for mail order and shipping operations.

- Consumer Goods: Suitable for packaging household items, personal care products, and other consumer goods.

Conclusion

The Hugo Beck Servo X 800 offers a reliable and efficient solution for high-quality, large-format film packaging. With its high precision, flexibility, and eco-friendly design, this machine is an excellent choice for businesses looking to optimise their packaging operations and reduce their environmental footprint. Invest in the Hugo Beck Servo X 800 to achieve superior packaging results and enhance your production efficiency.

Please feel free to contact us for more detailed information and to explore how the Servo X 800 can benefit your operations.

| Product infeed | manual as standalone/automatic in line |

| Film | centre-folded and flat film, e.g. PE, PO, PP, bio films, recycled content films |

| Product Size | Length: from 150 mm Width: 150 – 800 mm Height: max. 450 mm |

| Capacity | up to 5000 cycles/hour up to 84 cycles/minute |

| Versions | Side seal, bottom overlap with or without sealing/ionisation |

- Extremely tight bag packaging with lowest possible material use and optimum processing of the most diverse of film thickness and film types (e.g. recyclable mono-material films, recycled content films, ultra thin films from approx. 7 μm, etc.)

- Siemens TIA Portal or Rockwell Automation control system; free remote service

- Smart user guidance via CoPilot and touch screen

- Maximum serviceability and maintainability thanks to perfect access and numerous maintenance-free components

- Easy line integration and connectivity with higher-level systems, Industry 4.0 Ready

- Optional monitoring, analysis and visualisation of machine and operating data via the Hugo Beck Cockpit

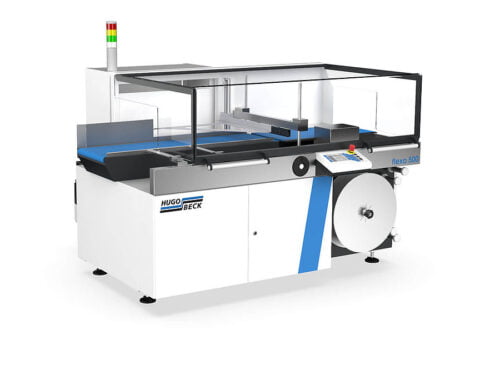

Side Seal

Side sealing machines with film waste rewinders pack products with a lateral cut seal. As an option, machines can include a non-stop film waste disposal in production. Many different products can be bagged with Hugo Beck’s form fill and seal machines. Bags can be completely shrunk or simply sealed at the sides. No exchange parts are required to cope with different product sizes.

The lateral cut seal guarantees a high-quality pack finish without any film remaining on the product. Thanks to our patented tight packaging only as much film is used as is truly needed! This not only guarantees an unrivalled and outstanding finish to the film packaging, depending on the machine type, a film saving of up to 15% is also delivered.

The “side seal” packaging style can be produced at performance speeds of up to 80m/min.

Hugo Beck packaging machines process all types of machine-compatible films at maximum speeds including those that are considered problematic, for example due to their sealing ability, such as extremely thin packaging films available from just 7μm (e. g. polyolefin), 100% recyclable films made from monomaterials (e. g. polypropylene) and those made from recycled materials and bioplastics (e. g. PLA films).

Bottom Overlap Thermo Seal/Static Seal

This overlap seal is applied in the middle of the product below. Hugo Beck uses the technology of seal welding or ionisation (with shrinking). This allows the overlap to be set centrally or laterally.

With fixed or adjustable forming shoulders, the film sleeve is optimally produced.

Speeds of up to 80 m/min are achievable with a bottom overlap and there is no film waste.