Hugo Beck Robots & Handling Systems

EFFICIENT AND FLEXIBLE AUTOMATION SOLUTIONS

Hugo Beck can claim a decade-long development tradition when it comes to automation. They offer support with their expertise throughout the entire automation process, from project planning and manufacture right through to integration into complex packaging lines.

Handling systems such as portals, grouping solutions, stacking and counting devices, cross pusher to name but a few, are integrated reliably into the packaging solutions by our technicians.

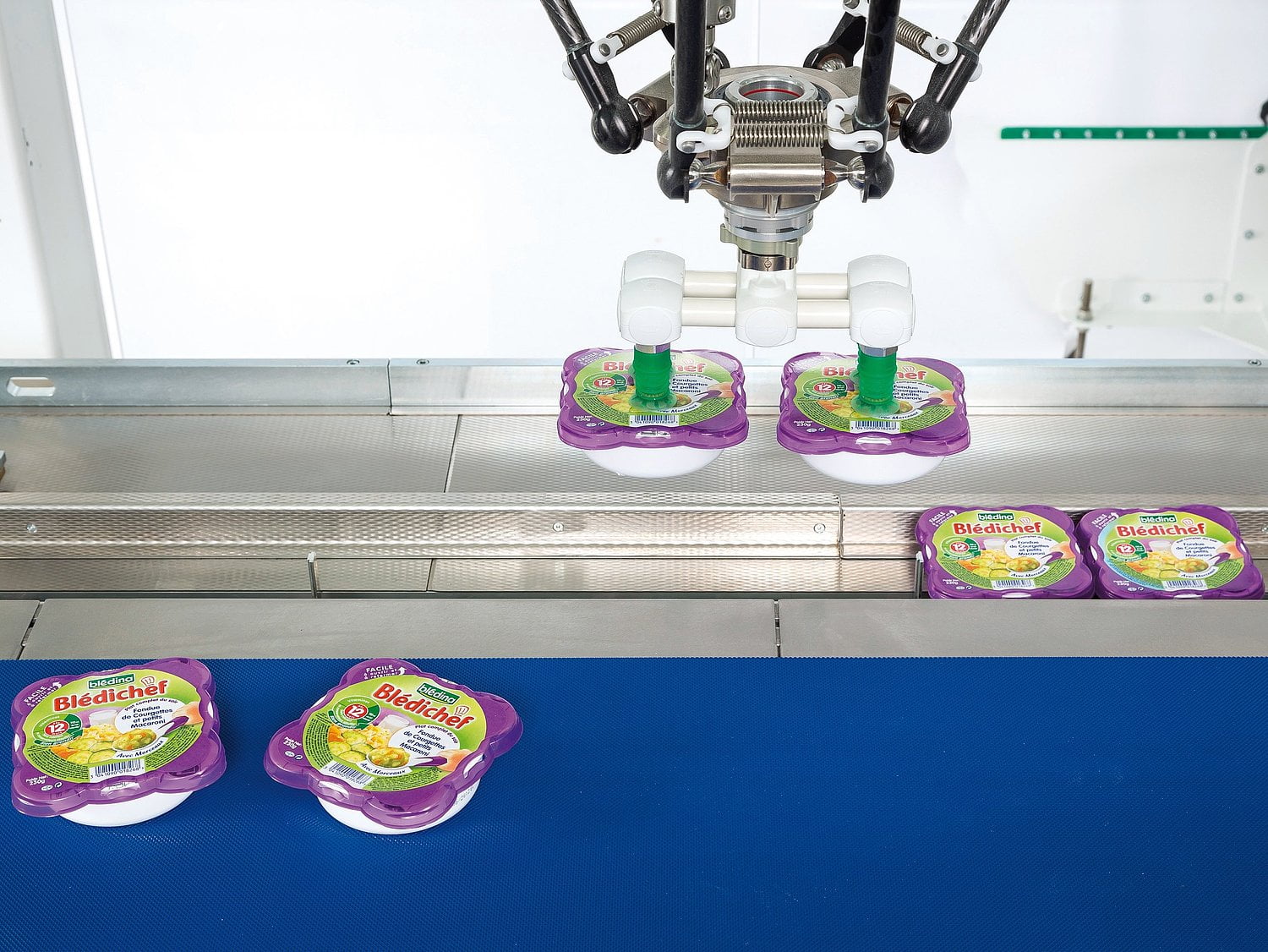

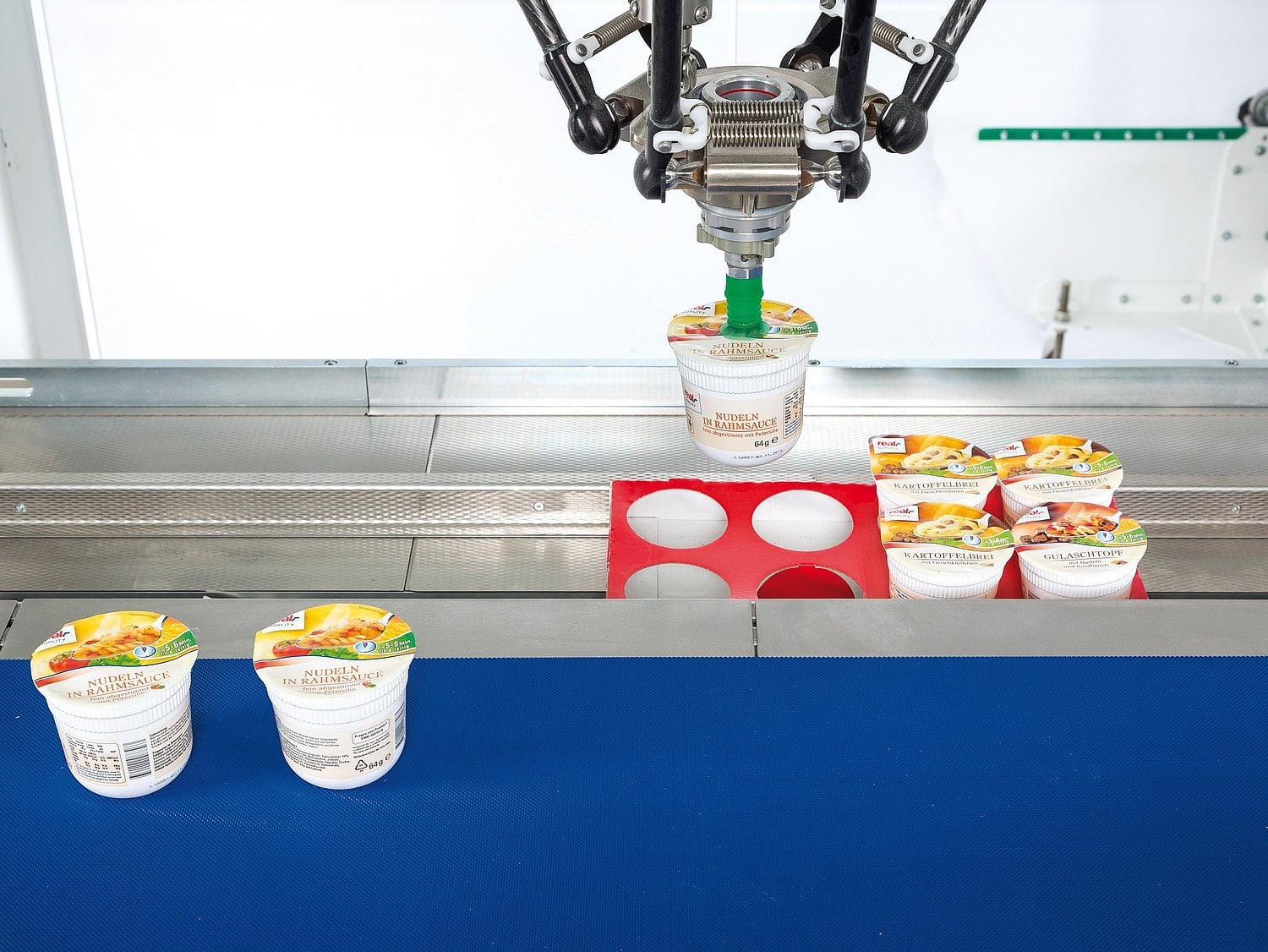

Furthermore, various robots systems are used across many industries for the automated feeding of products, helping to for example grip, position, stack, group, stage products. From a parallel robot (also known as a spider robot) all the way through to a SCARA robot – anything is flexibly possible and delivered fully integrated according to each customer‘s needs.

Both robots and handling systems can all be purchased independently of Hugo Beck packaging machines.

Integrated packaging robot system

The video shows a 6-axis articulated robot of Omron integrated into a Hugo Beck flowpack packaging line.

Robotic automation for co-packers

Each packaging machine and any automated robot solution can be adjusted to cope with each new product.

Automation applications with high-speed robot technology

An automated robotic product infeed system for film packaging applications in different industries.

Automation in post-print processing with parallel robot

An automated high-speed robotic product infeed system, coupled with film packaging applications for the print and paper industry.

Hugo Beck Robots & Handling Systems

Overview

The Hugo Beck Robots & Handling Systems are integral components of the company’s automation solutions, designed to enhance efficiency and precision in various packaging processes. These systems include a range of robots and handling devices that can be customised and integrated into complex packaging lines, providing versatile and reliable automation for diverse industries.

Key Features

- Customised Handling Systems: Tailored to meet specific customer needs, these systems can handle tasks such as gripping, positioning, stacking, grouping, and staging products.

- Flexible Technology Options: Includes a variety of robot systems, from parallel robots (spider robots) to SCARA robots, ensuring flexibility in application.

- Independent Operation: Robots and handling systems can be purchased independently of Hugo Beck packaging machines, allowing for integration with third-party devices.

- Integration Expertise: Hugo Beck provides support throughout the entire automation process, from project planning to integration into existing packaging lines.

Technical Specifications

- Robot Types:

- Parallel Robots (Spider Robots): Ideal for high-speed, precise handling tasks.

- SCARA Robots: Suitable for tasks requiring high precision and speed in a compact footprint.

- 6-Axis Articulated Robots: Used for complex, multi-directional movements and tasks.

- Handling Systems:

- Portals: For overhead handling and movement of products.

- Grouping Solutions: For organising products into groups or batches.

- Stacking and Counting Devices: For precise stacking and counting of products.

- Cross Pushers: For lateral movement and positioning of products.

Benefits

- Efficiency: Enhances productivity by automating repetitive and labour-intensive tasks.

- Precision: Ensures accurate handling and placement of products, maintaining high-quality standards.

- Flexibility: Can be adapted to various production requirements and integrated with different systems.

- Reliability: Built with robust materials and advanced technology for long-term operation with minimal maintenance.

Applications

The Hugo Beck Robots & Handling Systems are suitable for a variety of sectors, including:

- Pharmaceutical & Medical Technology: Ensures hygienic and precise packaging of medical products.

- E-Commerce & Logistics: Enhances packaging and handling processes for mail order and shipping operations.

- Food Industry: Automates packaging of dairy products, meat, fish, and other food items.

- Print & Multimedia: Ideal for handling and packaging magazines, catalogues, and other print products.

- Consumer Goods: Suitable for packaging household items, personal care products, and other consumer goods.

- Electronics: Ensures secure and precise packaging of electronic goods and components.

Conclusion

The Hugo Beck Robots & Handling Systems provide a comprehensive and flexible solution for automating various packaging processes. With their advanced technology, customisation options, and integration capabilities, these systems are an excellent choice for businesses looking to enhance efficiency, precision, and reliability in their production lines. Invest in Hugo Beck’s automation solutions to optimise your packaging operations and achieve high-quality results.

For more detailed information and to explore how the Robots & Handling Systems can benefit your operations, please contact us.

- Complete solutions from a single source

- Flexible technology options

- Customised handling systems

- Integration of robot systems from a variety of manufacturers

- Integration into existing and projected packaging lines