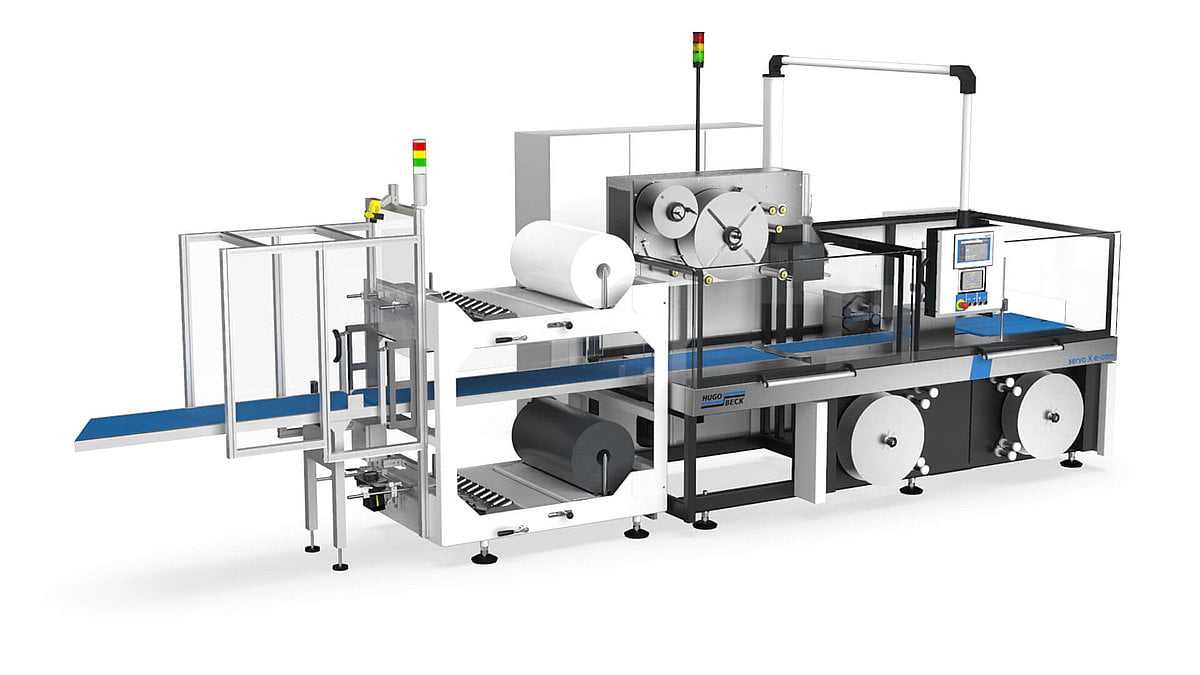

Hugo Beck Paper E-Com Fit

Paper packaging with two sewn sides for e-commerce, mail order, logistics.

With the paper e-com fit you are optimally equipped to meet the demands of sustainable paper packaging for the e-commerce, mail order and logistics sectors.

Whether dealing with the direct dispatch of individual goods, packing groups of products or meeting the complex requirements of returned goods packaging for example, the paper e-com fit packs goods with a minimum use of paper.

Both uncoated and coated recyclable papers can be used for producing precisely fitting paper bags with two sewn sides plus a top overlap.

The shipping bag size is automatically adapted to the varying product dimensions in length and width during production. Thus, different product sizes can be packaged in a jumble.

Furthermore, the packaging machine offers the possibility of storing two paper rolls of different widths. After the product scan, the machine then decides how wide the paper web must be and selects one of the two paper rolls. This minimises paper use.

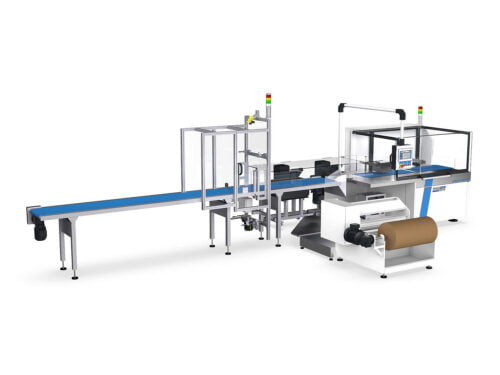

WILDPLASTIC® shipping film bags for E-Commerce

Our servo X e-com (fit) packaging machines can handle shipping bags made from WILDPLASTIC®. The term “wild plastic” describes all the plastic that currently exists outside the closed recycling loop – in streets, illegal and open dumps, and in nature. Such bags are already being used by OTTO in the mail order business. The bag size is automatically adapted to varying product sizes in length and width.

Film Packaging for E-Commerce (with upper-/lower film)

The servo X e-com, operating with upper and lower film (e.g. recycled content film), features for example scanning of invoice barcodes, product length measuring for precisely fitted shipping bags, continuous application of the shipping label and optimised user-friendliness.

Precisely fitted shipping film bags for E-Commerce (with upper-/lower film)

The servo X e-com fit, operating with upper and lower film (e.g. recycled content film), features for example scanning of invoice barcodes, product length and width measuring for precisely fitted shipping bags, continuous application of the shipping label and optimised user-friendliness.

Hugo Beck Paper E-Com Fit

Overview

The Hugo Beck Paper E-Com Fit is a specialised paper packaging machine designed for the e-commerce, mail order, and logistics sectors. This machine is engineered to provide sustainable and efficient packaging solutions, optimising material use and adapting to varying product dimensions.

Key Features

- Automatic Size Adaptation: Automatically adjusts the shipping bag size to the product’s length and width, minimising material consumption.

- Dual Paper Roll Storage: Stores two paper rolls of different widths, allowing the machine to select the appropriate width based on the product dimensions.

- High Efficiency: Capable of up to 600 cycles per hour, ensuring high productivity.

- Sustainable Packaging: Uses both uncoated and coated recyclable papers, supporting eco-friendly packaging practices.

- Versatile Packaging Styles: Produces paper bags with two sewn sides plus a top overlap, ensuring secure and professional packaging.

Technical Specifications

- Product Infeed: Manual as standalone or automatic in line.

- Product Size: Length from approximately 80 mm to 525 mm.

- Capacity: Up to 600 cycles per hour.

- Paper Types: Uncoated and coated papers of approximately 80 g/m².

- Packaging Styles: Two sides sewn with top overlap glued.

Benefits

- Efficiency: High-speed operation and automatic size adaptation streamline the packaging process, reducing downtime and increasing throughput.

- Flexibility: Capable of handling a variety of product sizes and types, making it suitable for diverse e-commerce and logistics applications.

- Sustainability: Supports the use of recyclable and eco-friendly paper materials, reducing environmental impact.

- Precision: Ensures consistent, high-quality packaging with minimal material waste.

Applications

The Hugo Beck Paper E-Com Fit is suitable for a variety of sectors, including:

- E-Commerce and Logistics: Ideal for packaging individual goods, groups of products, and returned goods, enhancing packaging flexibility and efficiency.

- Consumer Goods: Suitable for packaging household items, personal care products, and other consumer goods, ensuring secure and sustainable packaging.

Conclusion

The Hugo Beck Paper E-Com Fit offers a reliable and efficient solution for sustainable paper packaging in the e-commerce and logistics sectors. With its high precision, flexibility, and eco-friendly design, this machine is an excellent choice for businesses looking to optimise their packaging operations and reduce their environmental footprint. Invest in the Paper E-Com Fit to achieve superior packaging results and enhance your production efficiency.

Please feel free to contact us for more detailed information and to explore how the Paper E-Com Fit can benefit your operations.

| Product infeed | manual as standalone/automatic in line |

| Product size | Length: approx. 80 – 525 mm Width: approx. 80 – 675 mm Height: max. 200 mm |

| Capacity | approx. 600 cycles/hour |

| Paper | uncoated and coated of approx. 80 g/m2 to 130 g/m2 |

| Packaging style | two sides swen, top overlap glued |

- Each bag size is automatically adapted to the varying product dimensions in length and width

- Storing paper rolls of two different widths enables reduced paper consumption

- As an option, easy-opening perforation and inserting of a double-sided adhesive tape for resealing the bag

- Siemens TIA Portal or Rockwell Automation control system; free remote service

- Connection to ERP or control systems

- Integrated scanner with a controller for product detection and creation of a shipping label

- Optional monitoring, analysis and visualisation of machine and operating data via the Hugo Beck Cockpit

s=”wp-image-5942 size-medium aligncenter” src=”https://introtek.co.za/wp-content/uploads/2024/01/hugo-beck-two-sides-sewn-top-overlap-glued-300×225.jpg” alt=”” width=”300″ height=”225″ />

TWO SIDES SEWN, TOP OVERLAP GLUED

Various packaging techniques are applied to produce this paper packaging style with two sewn sides and glued top overlap.

Firstly, a paper banderole is placed around the product and hot-glued to the upper side. Any different product dimensions are detected by this packaging system with the dimension of the banderole adjusted to the product’s length and height. This enables a mix of differently sized products can be fed to the packaging machine.

The lateral closing units automatically adjust to the product width for each cycle. At this stage, the still open sides of the paper banderole are closed laterally by means of sewing. Simultaneously, rotating knives cut off any excess paper.

This style of paper bag packaging is available with the paper e-com fit. The machine offers the possibility of storing two paper rolls of differing widths. After the product scan, the packaging machine intelligently decides how wide the paper web must be and selects the best paper roll to use, maximising efficiencies and minimizing paper use.