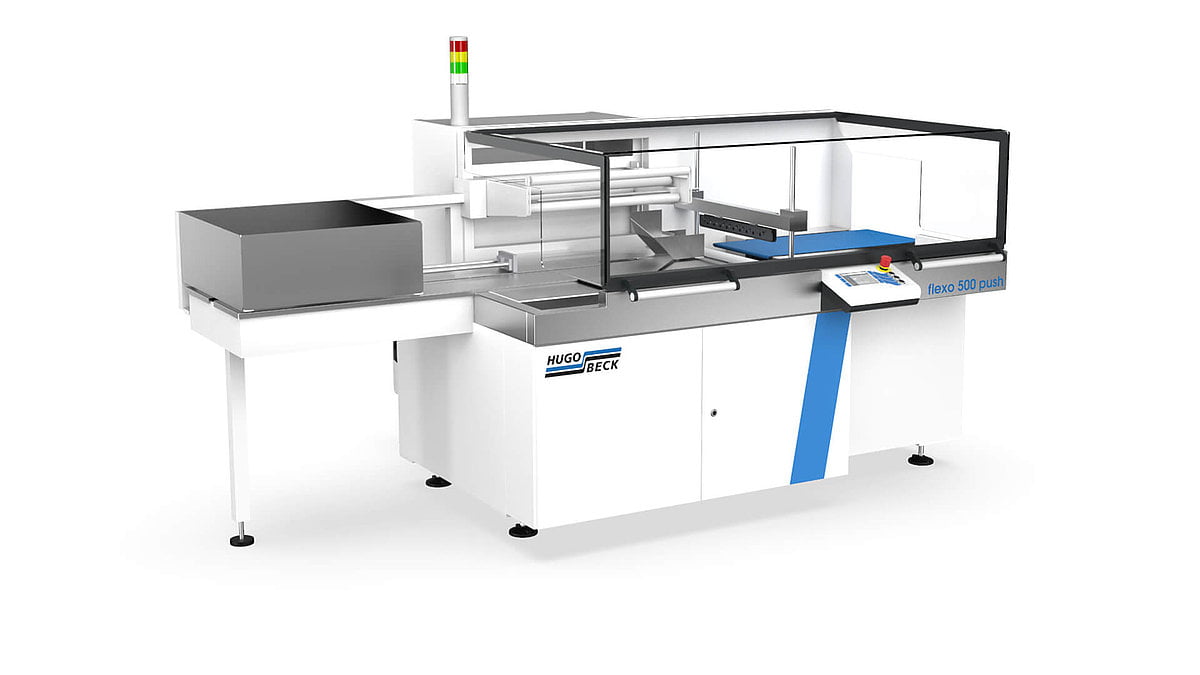

Hugo Beck Flexo H

A flexible all-rounder for wood and long parts from 800 mm in length.

The high-performance and extremely flexible intermittent Form Fill and Seal machine flexo H is particularly suitable for film packaging of wood and similar long parts from 800 mm in length, such as parquet or laminate, mouldings, wood or laminated wood, furniture parts or doors. It takes just five minutes to deal with a pallet of laminate.

Similarly, our flexible packaging machines are ideal for similar length products, including skis and snowboards, spirit levels, rolled goods, steel pipes, and many more items.

Hugo Beck Flexo H

Overview

The Hugo Beck Flexo H is a versatile form fill and seal machine designed specifically for packaging long and bulky items, such as wood products, furniture parts, and other elongated goods. This machine is known for its flexibility, high performance, and ability to handle a variety of packaging materials.

Key Features

- Flexible All-Rounder: Ideal for packaging wood and other long parts, ensuring secure and efficient packaging.

- High-Speed Operation: Capable of handling high packaging speeds, ensuring rapid processing and minimal downtime.

- Versatile Film Handling: Compatible with a wide range of films, including PE, PO, biofilms, and recycled content films.

- Modular Design: Allows for customisation and integration with other packaging solutions to meet specific industry needs.

Technical Specifications

- Product Infeed: Manual as standalone or automatic in line.

- Film Types: Centre-folded and flat film, such as PE, PO, biofilms, and recycled content films.

- Product Size: Suitable for long and bulky items, specifics can be tailored to customer requirements.

- Capacity: High throughput with speeds up to 70-80 metres per minute.

Benefits

- Efficiency: High-speed operation reduces cycle times and increases throughput, making it ideal for high-volume packaging needs.

- Flexibility: Can handle a wide variety of long and bulky products, from wood and laminate to furniture parts and steel pipes.

- Precision: Ensures tight-fitting and precise packaging, enhancing product appearance and reducing film usage.

- Sustainability: Eco-friendly design minimises film waste and reduces energy consumption, contributing to cost savings and environmental benefits.

Applications

The Hugo Beck Flexo H is suitable for a variety of sectors, including:

- Wood and Long Parts: Ideal for packaging items like parquet or laminate, mouldings, wood or laminated wood, furniture parts, doors, and other elongated goods.

- Industrial Products: Suitable for packaging steel pipes, rolled goods, and other long industrial items.

- Consumer Goods: Can handle large consumer items like skis, snowboards, and spirit levels.

Conclusion

The Hugo Beck Flexo H provides a robust, efficient, and flexible solution for packaging long and bulky items. With its high-speed capabilities, precision, and eco-friendly benefits, the Flexo H is an excellent choice for businesses looking to optimise their packaging operations. Invest in the Hugo Beck Flexo H to achieve superior packaging quality and operational efficiency.

Please feel free to contact us for more detailed information and to explore how the Flexo H can benefit your operations.

| Product Size | Length: from 800 mm Width: 80 – 400 mm Height: max. 200 mm |

| Film | centre-folded and flat film, e.g. PE, PO, bio films, recycled content films |

| Capacity | up to 1.200 cycles/hour up to 20 cycles/minute |

- High film savings due to processing of very thin films from 7 µm

- Reliable and robust side seals for any type of film

- Extremely quick adaptation without tools

- Data from formulations already run stored for repeat jobs

- Simple user guidance via touch screen; ability to store temperature settings for transversal sealing and side sealing

- Path control for reproducible format and performance settings

- High efficiency thanks to fast and simple film exchange; controlled winding of remaining film strip outside with soft start to prevent film from tearing

- Maximum serviceability and maintainability thanks to perfect access and numerous maintenance-free components

BOTTOM OVERLAP THERMO SEAL/STATIC SEAL

This overlap seal is applied in the middle of the product below. Hugo Beck uses the technology of seal welding or ionisation (with shrinking). This allows the overlap to be set centrally or laterally.

With fixed or adjustable forming shoulders, the film sleeve is optimally produced.

Speeds of up to 80 m/min are achievable with a bottom overlap and there is no film waste.