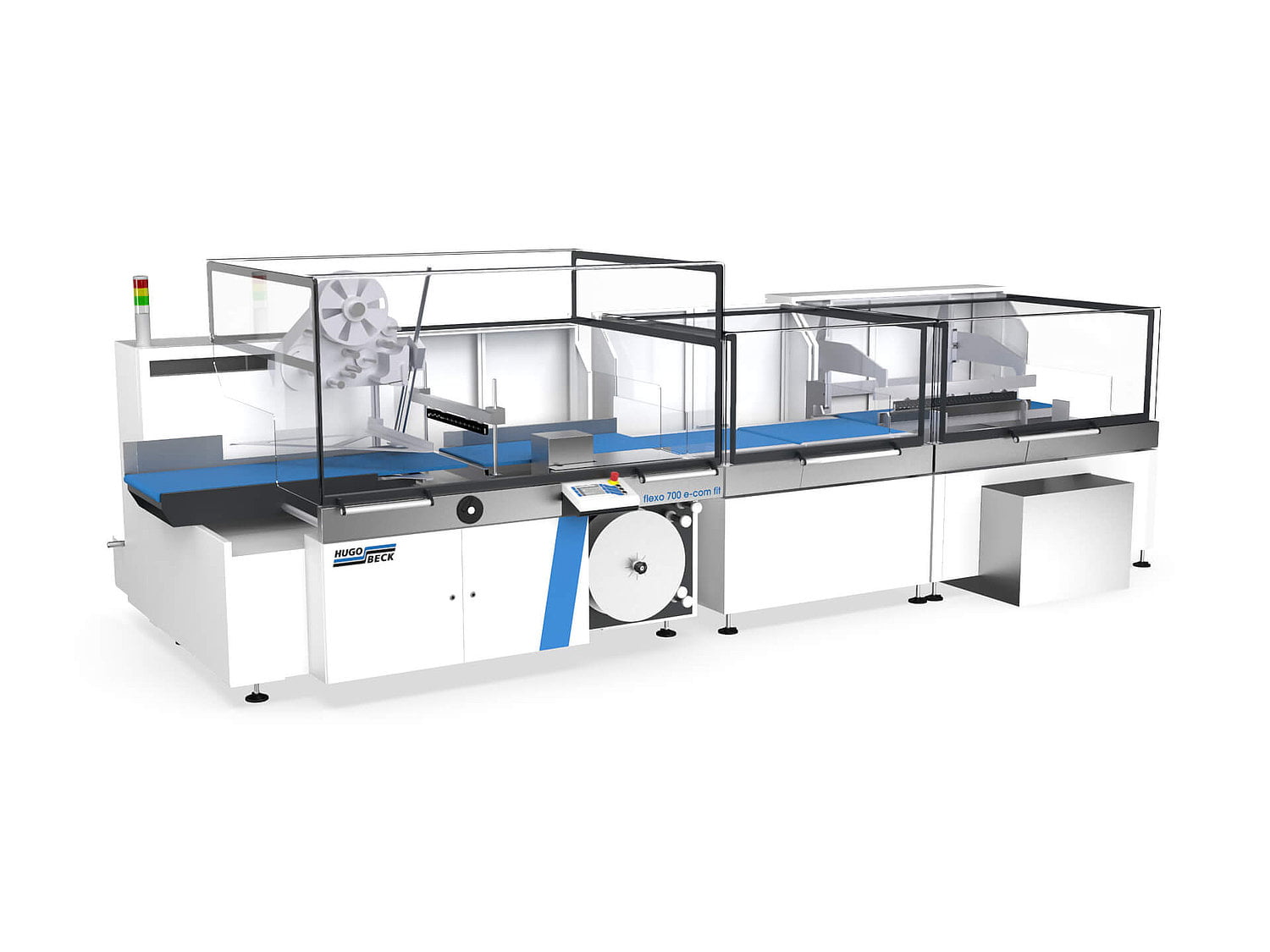

Hugo Beck Flexo 700 E-Com

Film packaging for e-commerce, mail order, logistics.

With the flexo 700 e-com you are optimally equipped to meet the demands of film packaging for the e-commerce, mail order and logistics sectors.

Whether dealing with the direct dispatch of individual goods, packing groups of products or meeting the complex requirements of returned goods packaging for example, the flexo 700 e-com packs goods with a minimum use of film and automatically adjusts the film bags to the product‘s length as standard.

To support the precise fitting of shipping bags, the flexo 700 e-com fit model also adjusts the bag size to the product’s width so that the machines fully automatically adjust to varying product sizes during the packaging process.

Additional options include the ability to add an easy-opening perforation to the bags as well as inserting a double-sided adhesive tape for resealing a bag for returns.

Film packaging for E-Commerce

The flexo 700 e-com packs goods with a minimum use of (centre-folded) film, maximising packaging results both with and without shrinking of the film bags. The bag size is automatically adapted to the product length and height as standard, optionally also to the product width.

Sustainable Paper Packaging for E-Commerce and More

The flexo paper packaging solution is our new cost-effective, space saving hybrid solution for film and paper packaging on one machine. The flexo paper packaging solution in the video is using Paptic® paper. The packaging machine is capable of handling coated, recyclable papers and all types of film. It can be changed between packaging materials in a matter of minutes.

Hugo Beck Flexo 700 E-Com

Overview

The Hugo Beck Flexo 700 E-Com is a state-of-the-art intermittent form-fill-and-seal machine specifically designed to meet the demanding needs of the e-commerce, mail order, and logistics sectors. This machine is engineered to handle various product sizes and packaging requirements, ensuring efficient and precise packaging with minimal film usage.

Key Features

- Automatic Size Adjustment: The Flexo 700 E-Com automatically adjusts the film bags to the product’s length and height, and optionally to the width, ensuring a snug fit for different product sizes.

- Minimal Film Usage: Packs goods with a minimum use of film, maximising material efficiency.

- Versatility: Suitable for direct dispatch of individual goods, packing groups of products, and handling complex returned goods packaging.

- Additional Options: Features such as easy-opening perforation and double-sided adhesive tape for resealing bags are available.

Technical Specifications

- Product Infeed: Manual as standalone or automatic in line

- Product Size:

- Length: From 100 mm

- Width: Up to 680 mm

- Height: Max. 300 mm

- Capacity: Up to 1,500 cycles per hour

- Film: Centre-folded film, e.g., PE 30-100 μm, recycled content films

Benefits

- Efficiency: High-speed operation with automatic size adjustments reduces downtime and increases throughput.

- Flexibility: Capable of handling a wide range of product sizes and film types, making it adaptable to various packaging needs.

- Precision: Ensures consistent, high-quality packaging with minimal film usage.

- Sustainability: Optimised for efficient material usage, reducing overall environmental impact.

Applications

The Hugo Beck Flexo 700 E-Com is ideal for a variety of sectors, including:

- E-Commerce and Logistics: Enhances packaging processes for mail order and shipping operations, ensuring efficient and precise packaging.

- Consumer Goods: Suitable for packaging household items, personal care products, and other consumer goods.

- Returned Goods: Efficiently handles the complex requirements of returned goods packaging with features like resealable bags.

Conclusion

The Hugo Beck Flexo 700 E-Com offers a reliable and efficient solution for high-quality, precise packaging tailored to the e-commerce and logistics sectors. With its automatic size adjustment, minimal film usage, and additional options for ease of use, this machine is an excellent choice for businesses looking to optimise their packaging operations. Invest in the Hugo Beck Flexo 700 E-Com to achieve superior packaging results and improve production efficiency.

For more detailed information and to explore how the Flexo 700 E-Com can benefit your operations, please contact us.

| Product infeed | manual as standalone/automatic in line |

| Product Size | Length: from 100 mm Width: 50 – 680 mm Height: max. 300 mm |

| Capacity | flexo 700 e-com: approx. 1500 cycles/hour flexo 700 e-com fit: approx. 1100 cycles/hour |

| Film | centre-folded film e.g. PE 30-100 μm, recycled content films |

- Tight bag packaging with lowest possible material use and optimum processing of the most diverse of film thickness and film types (e.g. recyclable mono-material films, recycled content films, etc.)

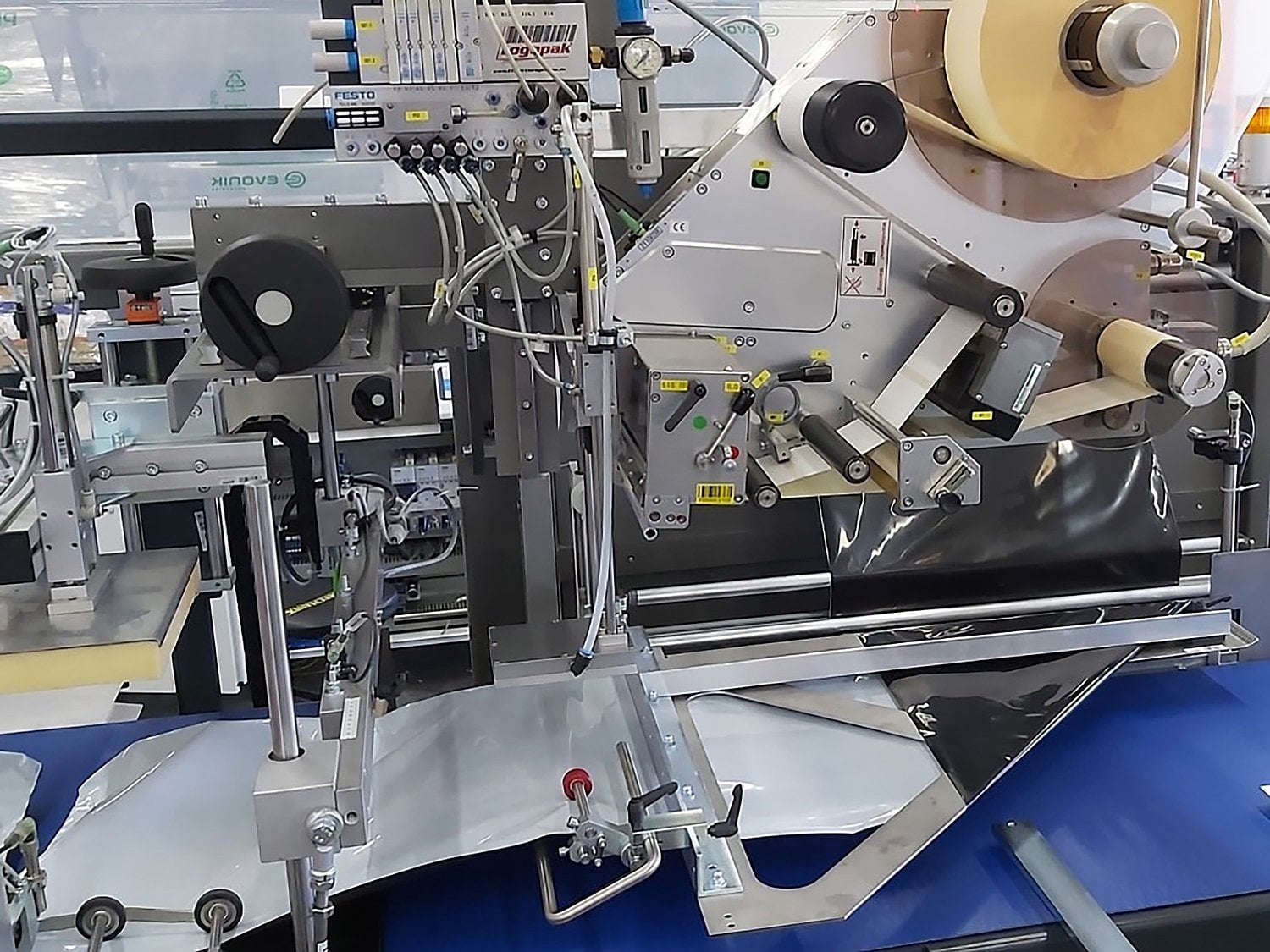

- Each bag size is automatically adapted to the product’s length as standard, and also to the product’s width as an option

- As an option, easy-opening perforation and inserting of a double-sided adhesive tape for resealing the bag

- Connection to ERP or control systems

- Integrated scanner with a controller for product detection and creation of a shipping label

- Free remote service

SIDE SEAL

Side sealing machines with film waste rewinders pack products with a lateral cut seal. As an option, machines can include a non-stop film waste disposal in production. Many different products can be bagged with Hugo Beck’s form fill and seal machines. Bags can be completely shrunk or simply sealed at the sides. No exchange parts are required to cope with different product sizes.

The lateral cut seal guarantees a high-quality pack finish without any film remaining on the product. Thanks to our patented tight packaging only as much film is used as is truly needed! This not only guarantees an unrivalled and outstanding finish to the film packaging, depending on the machine type, a film saving of up to 15% is also delivered.

The “side seal” packaging style can be produced at performance speeds of up to 80m/min.

Hugo Beck packaging machines process all types of machine-compatible films at maximum speeds including those that are considered problematic, for example due to their sealing ability, such as extremely thin packaging films available from just 7μm (e. g. polyolefin), 100% recyclable films made from monomaterials (e. g. polypropylene) and those made from recycled materials and bioplastics (e. g. PLA films).