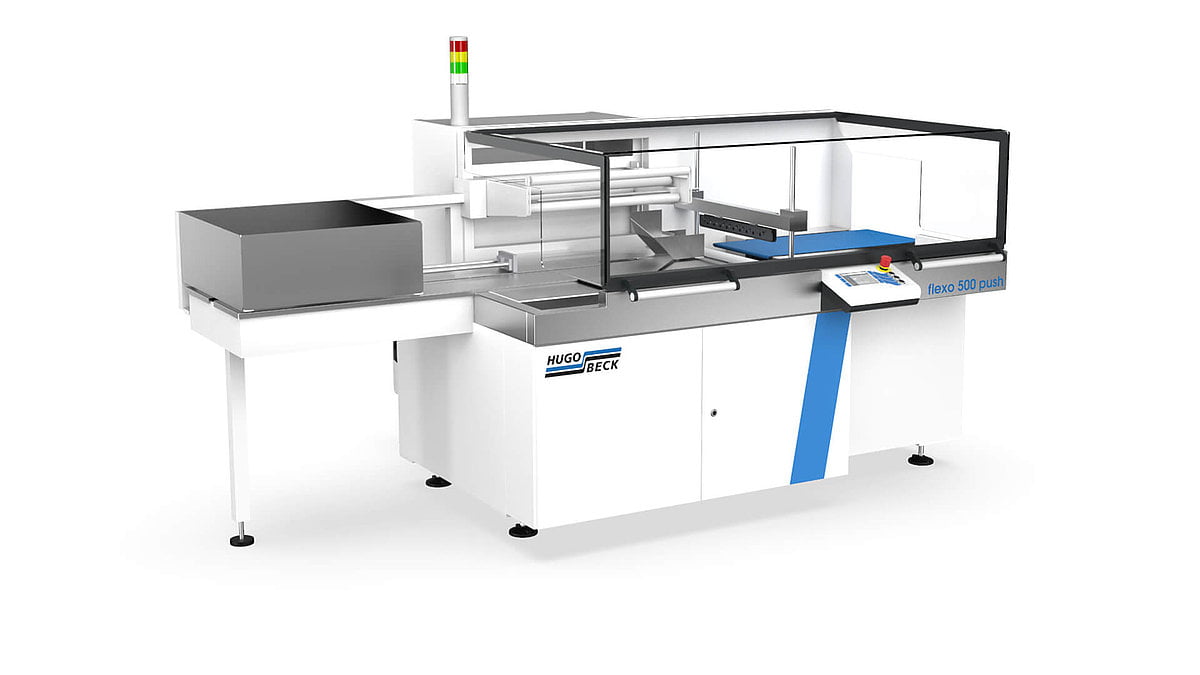

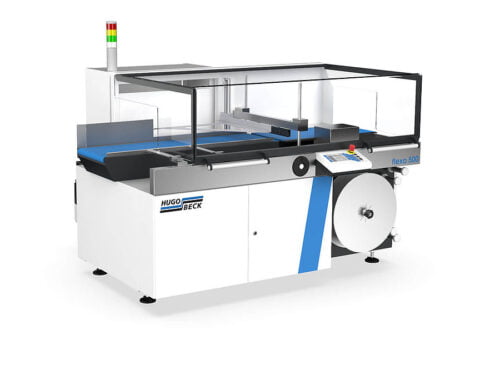

Hugo Beck Flexo 500/700 Push

Flexible pusher-machines for the packaging of bundles and difficult products.

The intermittent Form Fill and Seal machines flexo 500/700 Push are pusher-machines that wrap difficult products with ease, such as glass bottles in bundles or salt and pepper shakers.

They collect and group the products in order to subsequently push them into the film. In order to ensure that no products tilt over, our machines maintain physical contact with the articles to be packaged until they are safely in the bag.

The transversal sealing unit is designed as an intermittent version and processes a wide range of films and product dimensions. The packaging style features a bottom overlap.

Glass bottles grouped and shrink-wrapped

flexo pusher-machines wrap difficult products with ease, such as as glass bottles in bundles. They automatically collect and group items in order to subsequently push them into the film.

Film packaging of PET foodtainers in stacks

This video shows poly bagging of PET foodtainers in one or two stacks with a Hugo Beck flexo 500 Push film packaging machine.

Grouping and shrink wrapping of plastic containers

Hugo Beck Flexo 500/700 Push

Overview

The Hugo Beck Flexo 500/700 Push is an advanced intermittent form-fill-and-seal machine designed to handle a wide variety of films and product dimensions. With its flexible pusher mechanism, it is ideal for packaging bundles and challenging products, making it a versatile solution for various industries.

Key Features

- Intermittent Sealing: The transversal sealing unit operates intermittently, ensuring precise and consistent seals.

- Versatility: Capable of processing a broad range of films, including centre-folded and flat films like PE, PO, bio films, and recycled content films.

- High Capacity: The Flexo 500 can handle up to 6,000 cycles per hour, while the Flexo 700 can manage up to 5,000 cycles per hour.

- Large Format Capability: The Flexo 700 is specifically designed for large format products with a width of up to 680 mm.

- Flexible Product Infeed: Can be operated manually as a standalone unit or integrated into an automatic in-line system.

Technical Specifications

Flexo 500

- Product Infeed: Manual as standalone or automatic in line

- Film: Centre-folded and flat films

- Product Size:

- Length: From 100 mm (optional: 40 – ∞ mm)

- Capacity: Up to 6,000 cycles per hour

Flexo 700

- Product Infeed: Manual as standalone or automatic in line

- Film: Centre-folded and flat films

- Product Size:

- Length: From 100 mm (optional: 50 – ∞ mm)

- Width: Up to 680 mm

- Capacity: Up to 5,000 cycles per hour

Benefits

- Efficiency: High-speed operation and flexible design reduce downtime and increase throughput.

- Flexibility: Easily adapts to different product sizes and film types, making it suitable for various packaging requirements.

- Precision: Ensures consistent, high-quality seals for reliable packaging.

- Scalability: Suitable for both small and large format products, accommodating a wide range of applications.

Applications

The Hugo Beck Flexo 500/700 Push is suitable for a variety of sectors, including:

- Food and Beverage: Ideal for packaging items like frozen pizzas, biscuits, and fruit and vegetables.

- Pharmaceutical and Medical Technology: Provides secure packaging for medical containers and diagnostic equipment.

- E-Commerce and Logistics: Enhances packaging processes for mail order and shipping operations.

- Consumer Goods: Suitable for packaging household items, personal care products, and other consumer goods.

- Household Goods: Capable of packaging items like kitchenware, candles, and textile products.

Conclusion

The Hugo Beck Flexo 500/700 Push offers a reliable and efficient solution for diverse packaging needs. With its high precision, flexibility, and capacity to handle both small and large format products, this machine is an excellent choice for businesses looking to optimise their packaging operations. Invest in the Hugo Beck Flexo 500/700 Push to achieve superior packaging results and improve production efficiency.

For more detailed information and to explore how the Flexo 500/700 Push can benefit your operations, please contact us.

| Product Size | Length: max. 1000 mm Width: max. 600 mm Height: max. 300 mm |

| Film | centre-folded and flat film, e.g. PE, PO, bio films, recycled content films |

| Capacity | up to 900 cycles/hour up to zu 15 cycles/minute |

- High film savings due to processing of very thin films from 7 µm; there is no film waste

- Reliable and robust seals for any type of film

- Extremely quick adaptation without tools

- Data from formulations already run stored for repeat jobs

- Simple user guidance via touch screen; ability to store temperature settings for transversal sealing and side sealing

- Path control for reproducible format and performance settings

- High efficiency thanks to fast and simple film exchange

- Maximum serviceability and maintainability thanks to perfect access and numerous maintenance-free components

BOTTOM OVERLAP THERMO SEAL/STATIC SEAL

This overlap seal is applied in the middle of the product below. Hugo Beck uses the technology of seal welding or ionisation (with shrinking). This allows the overlap to be set centrally or laterally.

With fixed or adjustable forming shoulders, the film sleeve is optimally produced.

Speeds of up to 80 m/min are achievable with a bottom overlap and there is no film waste.