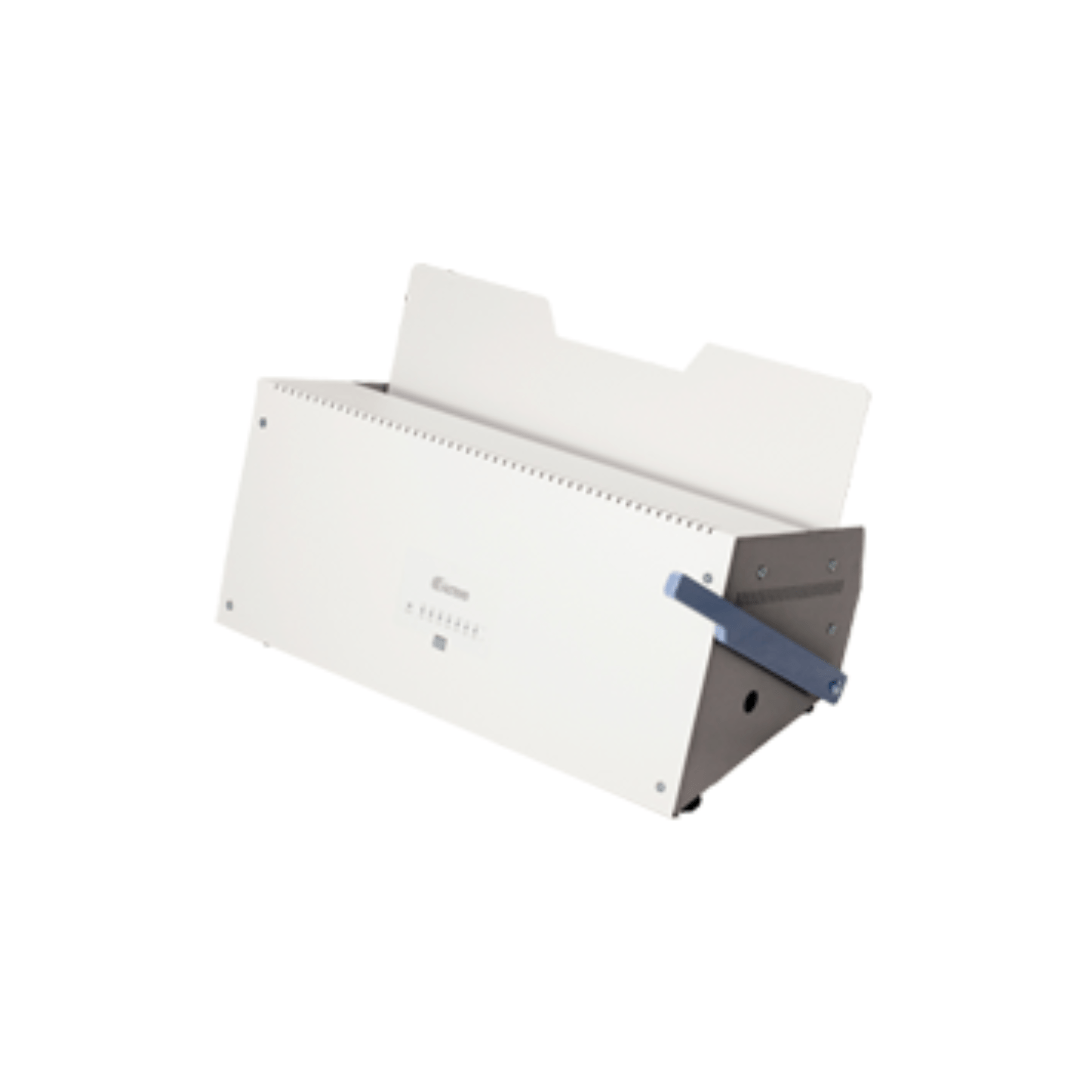

Groove Machine Fastbind Presso ™

The Fastbind Presso™ forms high-quality grooves in hard cover books. The Presso™ adds a touch of premium quality to any hard cover finishing job. Dramatically improve the appearance of all your hard cover books with Fastbind Presso™.

- Compact design

- Safe and easy to use

- Supports spine length up to 480 mm

Groove Machine Fastbind Presso ™

Overview

The Groove Machine Fastbind Presso ™ is a high-quality thermal press designed for creating precise grooves in hard cover books. This machine is ideal for professional bookbinding and print shops that require a premium finish for their hardback books.

Key Features

- Thermal Press: Utilises thermal technology to create deep, smooth grooves that hold tight against the book block.

- Quick and Easy Operation: After a brief warm-up period, simply place your hard cover book into the press, align the content, and press the button.

- High Efficiency: Capable of handling up to 200 cycles per hour, making it suitable for high-demand environments.

- Adjustable Settings: Features temperature adjustment (60–120°C) and pressure height adjustment in steps of 8, 10, 12, 14, and 16.

- Compatibility: Compatible with Fastbind Casemakers™, FotoMount, BooXTer, and Hot Melt Binders.

Technical Specifications

- Model: Presso™

- Machine Cycles/Hour: Up to 200

- Capacity Books/Hour: Up to 150 (depends on user)

- Max Binding Thickness: 40 mm / 1.57 inches

- Max. Pressing Length: 480 mm / 18.9 inches

- Voltage (V) / Frequency (Hz): 110-120/220-240 VAC / 50-60 Hz

- Max. Current: 6.3 A / 6.3 A

- Machine Dimensions (W x L x H): 53 x 43 x 31 cm / 21.0 x 13.0 x 12.2 inches

- Net Weight: 20.5 kg / 45.5 lbs

- Approvals: CE certified

Benefits

- Enhanced Appearance: Forms perfect grooves in hard covers, dramatically improving the finished look of hardback books.

- Consistency: Automated operation ensures uniform grooves across all covers, maintaining high quality.

- Time-Saving: Quick warm-up and automated process reduce manual labour and increase efficiency.

- Durability: Thermal technology provides strong and lasting grooves, enhancing the durability of the covers.

- Ease of Use: User-friendly interface makes it easy for operators to use the machine with minimal training.

Applications

The Groove Machine Fastbind Presso ™ is perfect for a variety of applications, including:

- Professional Bookbinding: Ideal for creating high-quality hardback books with precise and durable grooves.

- Print Shops: Suitable for print shops that require efficient and high-quality finishing for hard covers.

- Publishing Houses: Enhances the appearance and durability of published hardback books.

- Corporate Offices: Perfect for creating professional-looking reports, presentations, and other bound documents.

Conclusion

The Fastbind Presso™ is a reliable and efficient thermal press designed for professional environments that require high-quality grooving in hard covers. Its combination of advanced features, ease of use, and high efficiency makes it an excellent choice for businesses looking to enhance the appearance and durability of their hardback books.

Please feel free to contact us for more detailed information and to explore how the Fastbind Presso™ can benefit your operations.

| Machine cycles/hour | up to 450 |

| Capacity books/hour* | up to 300 |

| Max binding thickness | 45 mm / 1.77 inches |

| Max. pressing length | 480 mm / 18.9 inches |

| Voltage (V) / Frequency (Hz) | 110-120/220-240 VAC/50-60 Hz |

| Max. current | 1.3 A / 1.3 A |

| Machine dimensions (W x L x H) | 55 x 33 x 31 cm / 21.7 x 13.0 x 12.2 inches |

| Package dimensions (W x L x H) | 62 x 40 x 39 cm / 24.4 x 15.8 x 15.4 inches |

| Net / gross weight | 15.2 kg / 33.5 lbs |

| Approvals | CE |

| * Depends on user. Product information as of June 2010 and is subject to change without notice. | |

Easy to use

Symmetrical, deep and smooth groove.

Quick and easy

The Fastbind Presso™ is a thermal press designed to make grooves quickly and easily. After a brief warm up period, the press is ready to go. Simply put your hard cover book into the press and pull the lever. Repeat for the other side, and you are done. Your hard cover books get symmetrical, deep, smooth grooves that hold tight against the book block…every time.

Compatible with Fastbind Casemakers™, FotoMount, BooXTer and Hot Melt Binders