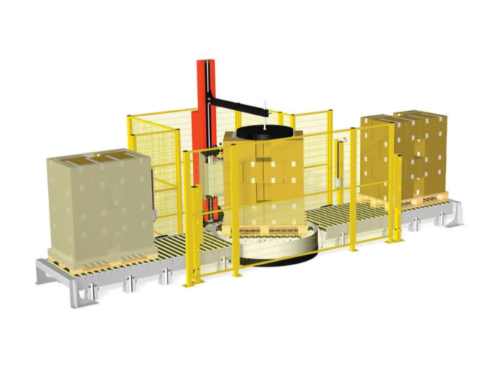

SOCO PW-1000 Semi-automatic pallet stretch-wrapper

For film with or without pre-stretch. Simple and efficient machine for the everyday job. The compact size facilitates location and relocation. The PW-1000 is available for different-sized pallet loads (see table).

For film with or without pre-stretch. Simple and efficient machine for the everyday job. The compact size facilitates location and relocation. The PW-1000 is available for different-sized pallet loads (see table).

Safety

The sealed tower, the emergency stop as well as the safety switch built into the foot plate under the film carriage make the PW-1000 a very safe machine.

The standard equipment includes, among other things:

- Independent setting of film carriage and turntable speed, which makes it possible to fully utilize the film and to determine the extent of film overlap.

- Soft start on turntable. A great advantage where pallet loads are light or fragile. The turntable starts up slowly and then accelerates until the required speed has been reached.

- Memory stores the last used settings for the turntable and film carriage speeds.

- Program for rainproof pallet stretch-wrapping, offering efficient protection against rain and humidity (requires separate top film application).

- Automatic setting of pallet load height, a photocell registers the height of the pallet load.

- Variable number of wraps at top and bottom available upon selection (1-9).

- Independent setting of turntable and up/down speed of film carriage during operation as required.

- The option of manual operation and, with this, the possibility of choosing, for instance only top wrapping.