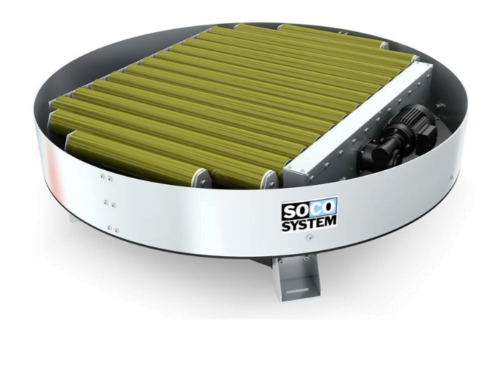

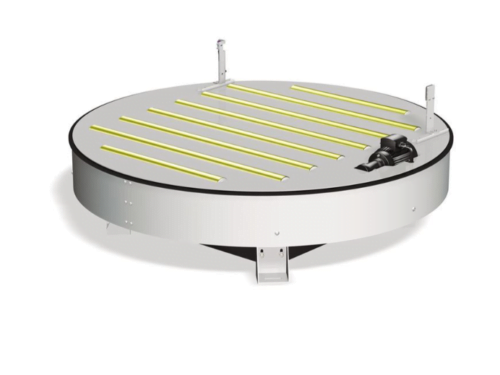

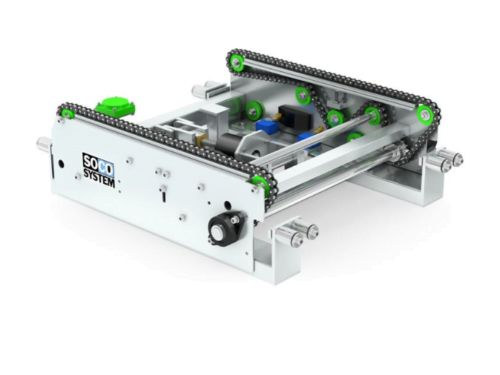

SOCO Pallet magazine PalManager Fixed – Ready for MiR AMR

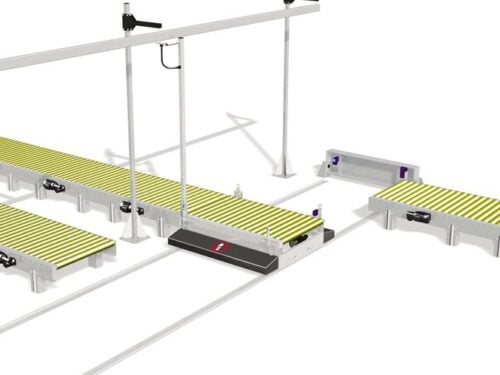

The pallet magazine is used for stacking of up to 14 pallets or as a pallet magazine from where MiR can collect one pallet at a time.The pallet magazine is prepared for communication with MiR, and together they form a fully automatic pallet flow, e.g. in connection with transport to or from warehouse or as part of a fully automatic palletising system. Pallet magazine PalManager Fixed is prepared for MiR with MiR EU Pallet Lift or with MiR Pallet Lift for closed pallets.

The pallet magazine is used for stacking of up to 14 pallets or as a pallet magazine from where MiR can collect one pallet at a time.The pallet magazine is prepared for communication with MiR, and together they form a fully automatic pallet flow, e.g. in connection with transport to or from warehouse or as part of a fully automatic palletising system. Pallet magazine PalManager Fixed is prepared for MiR with MiR EU Pallet Lift or with MiR Pallet Lift for closed pallets.

See more on MiR at Mobile Industrial Robots

Ready for MiR AMR function:

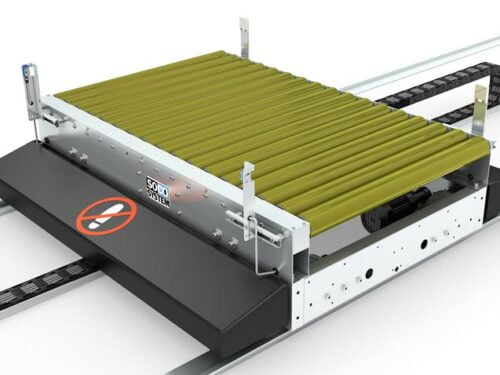

- The MiR can collect a pallet from the PalManager.

- The MiR can deliver a pallet to the PalManager.

- The MiR can collect a full pallet stack from the PalManager.

Ready for MiR AMR comprises:

- The PalManager comes equipped with WISE-4060 wi-fi or WISE 4060 LAN (optional).

- The PalManager software is prepared for communication with MiR.

- The pallet magazine is as standard equipped with photocells releasing an alarm when the maximum or minimum number of pallets in the pallet magazine is reached.

- Manual with description of integration with MiR.

The PalManager is connected to the same local network to which the MiR is connected.

Advantages:

- Fully automatic pallet handling.

- Safe pallet handling – fewer work-related injuries.

- Increases productivity – always a pallet ready for use.

- Gentle pallet handling.

- No noise or dust inconvenience.

- Provides order both in storage and production.

PalManager Fixed – Ready for MiR AMR is currently available in a pneumatic version.