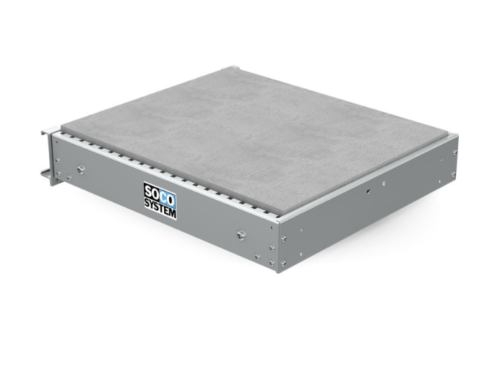

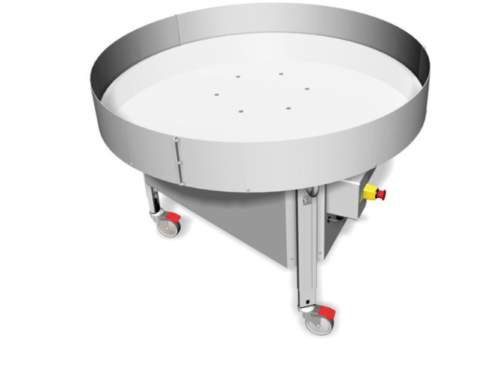

A simple and cost-efficient solution to accumulation. SOCO SYSTEM’s rotary table is suitable for accumulation of e.g. retail products. The operator is free to perform other jobs, while, at the same time, interruption of the arrival of products is avoided.

A simple and cost-efficient solution to accumulation. SOCO SYSTEM’s rotary table is suitable for accumulation of e.g. retail products. The operator is free to perform other jobs, while, at the same time, interruption of the arrival of products is avoided.

Rotating on the table, the articles are constantly within easy reach. A rational workstation offering correct working conditions. A fan directs the products, and the table is prepared for side guides. The legs are height adjustable.

Diameter: Ø 1200 mm.

Height: Min. 715 mm.

Speed: Standard 6.00 rotations per minute. Upon request 3.77, 2.81 and 2.20 rotations per minute are available. Adjustable speed control can also be supplied.

The rotary table is available in three different versions:

Model A: Rotary table with plastic laminated tabletop.

Model B: Rotary table with tabletop made of solid plastic.

Model C: Rotary table in 18/8 stainless steel with tabletop made of solid plastic.

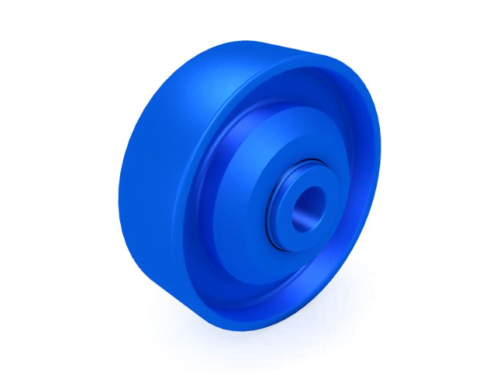

Braked castors: SOCO SYSTEM castors are of sturdy construction with efficient brakes that lock in the direction of travel and rotation.

Standard on SOCO SYSTEM rotary tables.