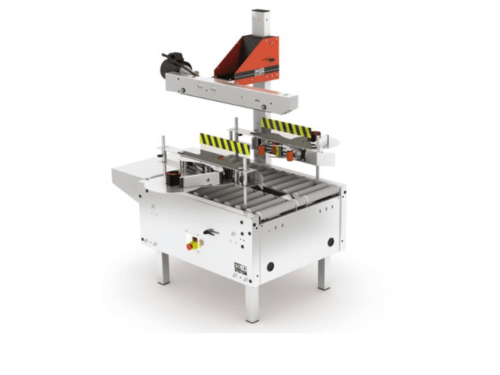

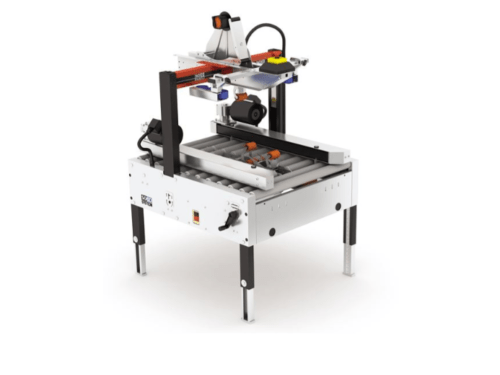

SOCO HM-4200 case sealer with automatic flap folding

Top sealing with hotmelt. Inlet control with SOCO SYSTEM controller ensures efficient carton separation and high capacity.

Top sealing with hotmelt. Inlet control with SOCO SYSTEM controller ensures efficient carton separation and high capacity.

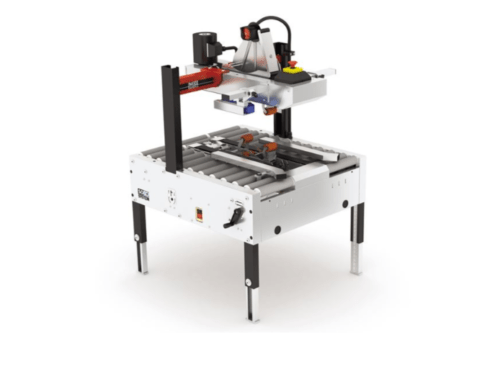

Basic models

The compact machine is available in two sizes.

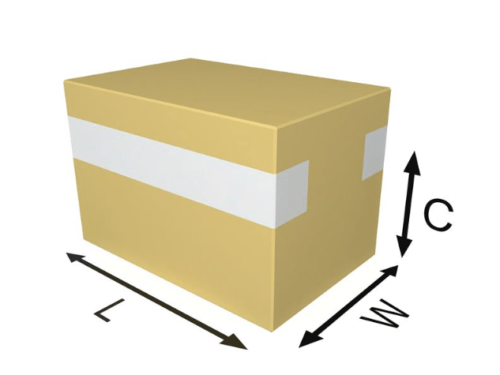

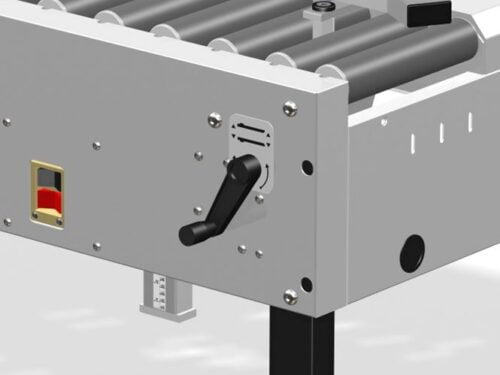

- The machine is very easy to adjust for different carton sizes and adjustment can be carried out from both sides.

- Compact design.

- Easy to maintain and low maintenance costs.

- Wide range of accessory equipment, e.g. braked castors, packaging tables, and conveyors.