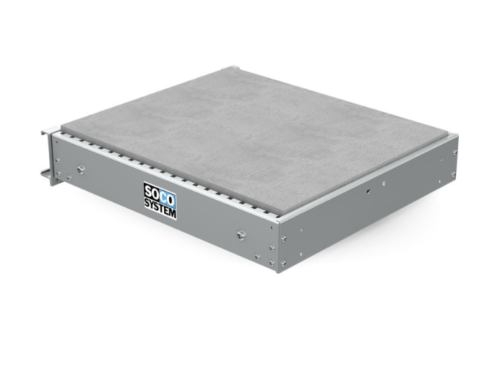

SOCO Packaging table for installation on roller conveyor

Complete packing table with plastic laminated plate. Easy to hook onto the side of a roller conveyor. The tables are available with or without case holder.

Complete packing table with plastic laminated plate. Easy to hook onto the side of a roller conveyor. The tables are available with or without case holder.

Efficient flexible packaging equipment and packaging systems.

Case erecting, Conveying, Case sealing, Pallet handling, Palletising & Pallet securing.

Showing 73–84 of 114 results

Complete packing table with plastic laminated plate. Easy to hook onto the side of a roller conveyor. The tables are available with or without case holder.

Complete packing table with plastic laminated plate. Easy to hook onto the side of a roller conveyor. The tables are available with or without case holder.

The pallet exchanger consists of 2 side modules bolted to the floor. The pallet fingers on the modules hold the pallet approximately 240 mm above the floor.

The pallet exchanger consists of 2 side modules bolted to the floor. The pallet fingers on the modules hold the pallet approximately 240 mm above the floor.

No pneumatic air or electricity is required. Pallet exchangers can be used for all pallet sizes.

The pallet loader can operate as a semi automatic unit, or it can be integrated into a fully automatic palletising system.

The pallet loader can operate as a semi automatic unit, or it can be integrated into a fully automatic palletising system.

More on the pallet

All cases, including heavy and bulky ones, can easily be stacked to heights of 2500 mm in order to fully utilise the capacity of lorries and containers.

Safe to operate, simple and versatile

The machine requires minimal maintenance and is easy to service.

The machine is available with either left or right-hand operation.

Simple and safe operation

The software is simple and self-explanatory, and is operated using a finger touch panel. When the stripper plate is filled, the operator steps onto a safety mat that deactivates the machine. The machine is supplied with safety screening.

Stainless steel for wet environments

The pallet loader and the rest of the product range are available in galvanised or stainless steel.

The machine can be ordered in special colours at a surcharge.

The PalManager Fixed is used for stacking of up to 14 pallets or as a pallet magazine from where the operator can collect one pallet at a time. The pallet magazine can be set for automatic stacking or unstacking. This model is available in three different widths.

The PalManager Fixed is used for stacking of up to 14 pallets or as a pallet magazine from where the operator can collect one pallet at a time. The pallet magazine can be set for automatic stacking or unstacking. This model is available in three different widths.

PalManager Fixed is available in pneumatic or electrical versions.

The pallet magazine is used for stacking of up to 14 pallets or as a pallet magazine from where MiR can collect one pallet at a time.The pallet magazine is prepared for communication with MiR, and together they form a fully automatic pallet flow, e.g. in connection with transport to or from warehouse or as part of a fully automatic palletising system. Pallet magazine PalManager Fixed is prepared for MiR with MiR EU Pallet Lift or with MiR Pallet Lift for closed pallets.

The pallet magazine is used for stacking of up to 14 pallets or as a pallet magazine from where MiR can collect one pallet at a time.The pallet magazine is prepared for communication with MiR, and together they form a fully automatic pallet flow, e.g. in connection with transport to or from warehouse or as part of a fully automatic palletising system. Pallet magazine PalManager Fixed is prepared for MiR with MiR EU Pallet Lift or with MiR Pallet Lift for closed pallets.

See more on MiR at Mobile Industrial Robots

Ready for MiR AMR function:

Ready for MiR AMR comprises:

The PalManager is connected to the same local network to which the MiR is connected.

Advantages:

PalManager Fixed – Ready for MiR AMR is currently available in a pneumatic version.

1-5 pallets at a time. PalManager GM5 is used for stacking of up to 16 pallets or as a pallet magazine from where the operator can collect one or more pallets at a time.

1-5 pallets at a time. PalManager GM5 is used for stacking of up to 16 pallets or as a pallet magazine from where the operator can collect one or more pallets at a time.

The pallet magazine can be set for automatic stacking or unstacking of 1-5 pallets at a time. The pallet magazine is electric and does not require any air connection.

Control system and operation

The PalManager GM5 is equipped with a unique and user-friendly control system that ensures high productivity at lowest possible costs. The pallet magazine is easy to operate and to set for the functions required.

The PalManager is used for stacking of up to 24 pallets or as a pallet magazine from where the operator can collect one pallet at a time. Safe, easy, and noiseless. The pallet magazine can be set for automatic stacking or destacking.

The PalManager is used for stacking of up to 24 pallets or as a pallet magazine from where the operator can collect one pallet at a time. Safe, easy, and noiseless. The pallet magazine can be set for automatic stacking or destacking.

PalManager High is available in pneumatic or electrical versions.

The pallet magazine is used for stacking of up to 24 pallets or as a pallet magazine from where MiR can collect one pallet at a time. The pallet magazine is prepared for communication with MiR, and together they form a fully automatic pallet flow, e.g. in connection with transport to or from warehouse or as part of a fully automatic palletising system.

The pallet magazine is used for stacking of up to 24 pallets or as a pallet magazine from where MiR can collect one pallet at a time. The pallet magazine is prepared for communication with MiR, and together they form a fully automatic pallet flow, e.g. in connection with transport to or from warehouse or as part of a fully automatic palletising system.

Pallet magazine PalManager High is prepared for MiR with MiR EU Pallet Lift or with MiR Pallet Lift for closed pallets.

See more on MiR at Mobile Industrial Robots

Ready for MiR AMR function:

Ready for MiR AMR comprises:

The PalManager is connected to the same local network to which the MiR is connected.

Advantages:

PalManager High in this version is currently available in a pneumatic version.

The PalManager Multi is used for stacking of up to 14 pallets or as pallet magazine from where the operator can collect one pallet at a time. Adjustable for different pallet widths. The pallet magazine can be set for automatic operation.

The PalManager Multi is used for stacking of up to 14 pallets or as pallet magazine from where the operator can collect one pallet at a time. Adjustable for different pallet widths. The pallet magazine can be set for automatic operation.

PalManager Multi is available in pneumatic or electrical versions.

This model is designed for 2000 mm pallets. The PalManager Multi Long is used for stacking of up to 14 pallets or as a pallet magazine from where the operator can collect one pallet at a time. The pallet magazine can be set for automatic stacking or unstacking.

This model is designed for 2000 mm pallets. The PalManager Multi Long is used for stacking of up to 14 pallets or as a pallet magazine from where the operator can collect one pallet at a time. The pallet magazine can be set for automatic stacking or unstacking.

The PalManager Multi Long is adjustable for different pallet widths.

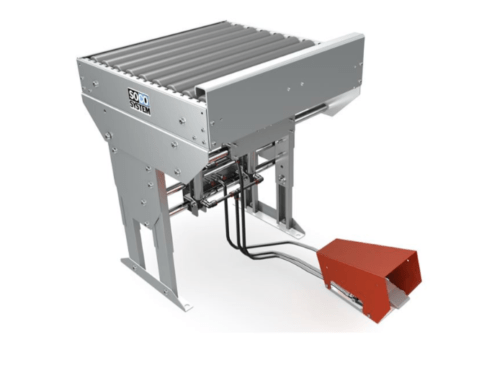

Table can be tilted 20°. Offers a good working position during filling of cases. The tilt table functions as a packaging table with an incline. The table is tilted by means of a compressed air cylinder operated by means of a foot pedal. The pneumatic tilt table is as standard delivered with rollers but is also available with plate.

The tilt table is available in two different versions:

Model A: Items will be directed straight forward after filling.

Model B: Items will be directed to the side after filling (see this model under features).

The flexible double robot has two pallet positions that can be utilised in several ways.

The flexible double robot has two pallet positions that can be utilised in several ways.

No waiting time during pallet change

The modular robot can palletise the same product onto two pallets. When one pallet is full, the robot automatically starts to palletise on the second pallet, allowing plenty of time to remove the first full pallet and replace it with an empty pallet.

Product sorting

The double robot can palletise two different products – one on each pallet. The two different products can arrive on the same infeed conveyor. Photocells or other sensor equipment will then tell the robot what product is to be palletised onto which pallet.

Double line operation

The double robot can handle two different products that arrive to the robot on two separate infeed conveyors – one from each production line. The robot takes each product to its own pallet.