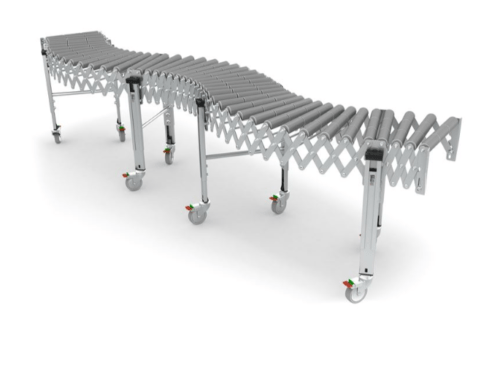

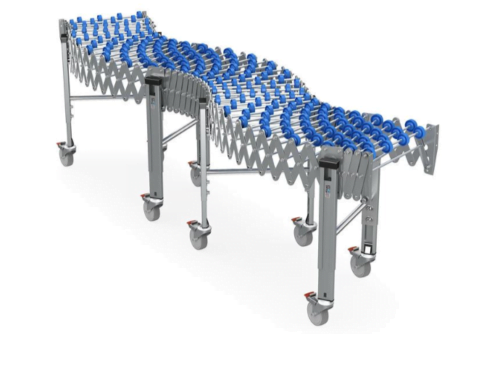

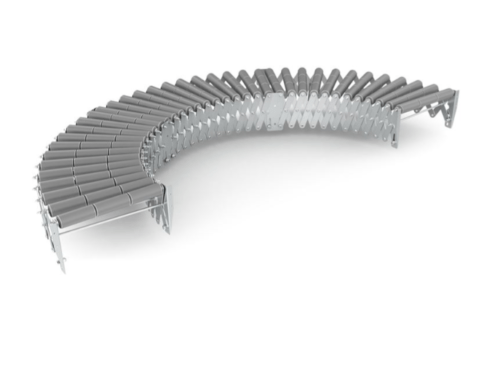

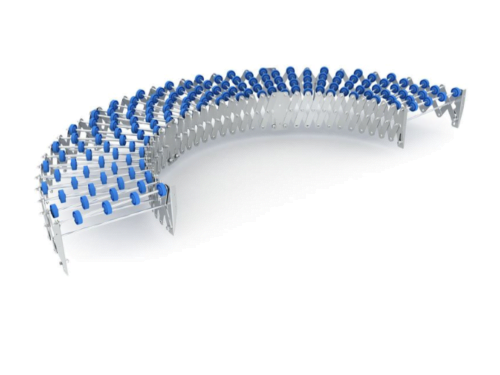

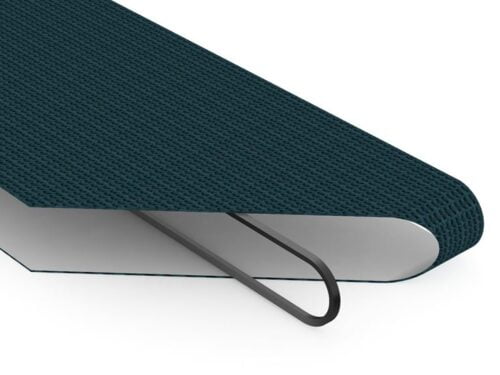

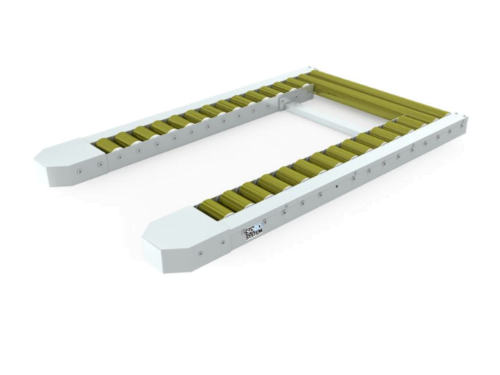

SOCO Flexi conveyors with 3-parted Ø 48 plastic rollers

Bend easily to suit requirements. Flexible roller conveyor for transporting plastic boxes and other items. The conveyor length can be varied according to requirements.

Bend easily to suit requirements. Flexible roller conveyor for transporting plastic boxes and other items. The conveyor length can be varied according to requirements.

- 3-parted axles offer low noise and smooth travel.

- The conveyor is fitted with height-adjustable supports with braked castors.

- Suitable in production and packaging for transporting uneven-based items.