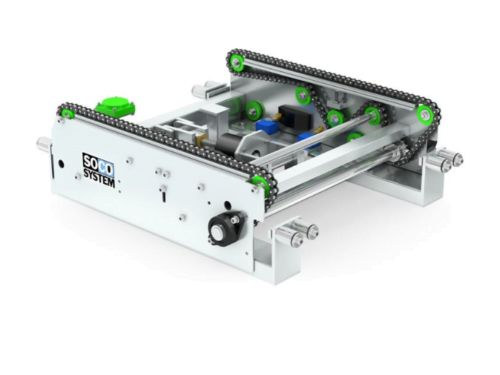

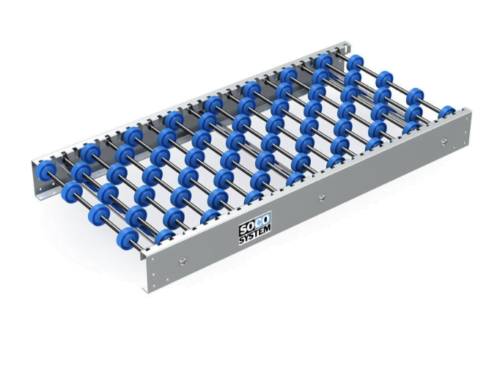

SOCO Transfer units

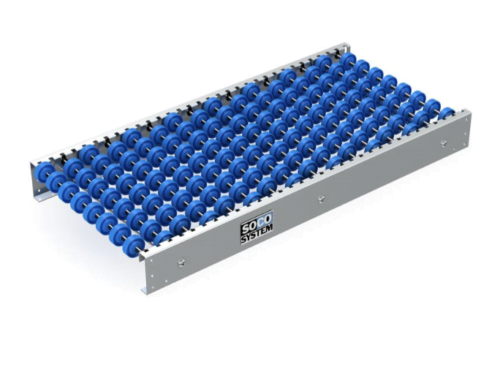

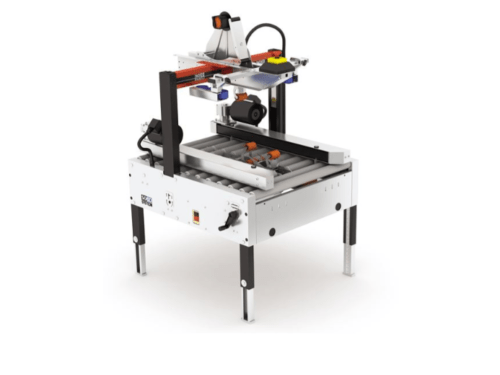

The transfer unit changes the pallet direction travel by 90°. The 90° transfer unit is a chain conveyor which is raised and lowered automatically above and below roller height.

The transfer unit changes the pallet direction travel by 90°. The 90° transfer unit is a chain conveyor which is raised and lowered automatically above and below roller height.

Can be fitted in all pallet roller conveyors where the height exceeds 350 mm.

Motors:

Two motors – one for up/down movement and one for chain movement.