Italdibipack Speed Bag H

![]()

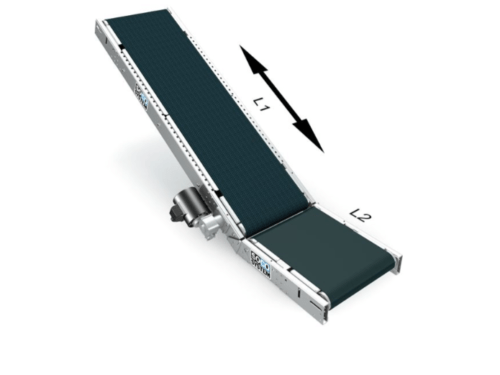

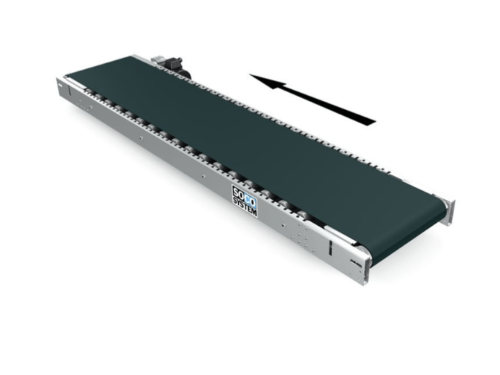

FAST AND INEXPENSIVE HORIZONTAL BAGGING

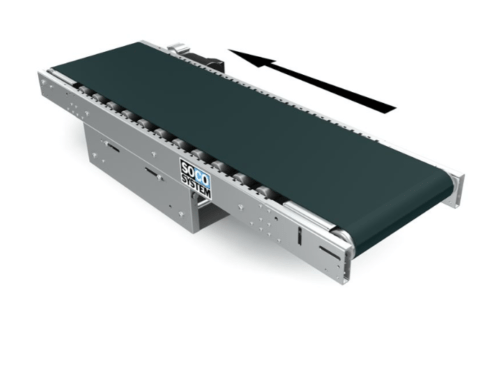

Ideal for wrapping and mailing newspapers and magazines, catalogues and wholesale publications, and any commercial printed materials in A4 size in single pack. Half-automatic, easy to use: the only thing the operator has to do is simply to feed products horizontally onto the infeed conveyor belt that carries them towards the sealing area. Here a special device will “clamp“ product and film together and push them through sealing and cutting operations. A bag is formed around the product by the adjustable width folding plates. The bag is then sealed and cut according to the product length.