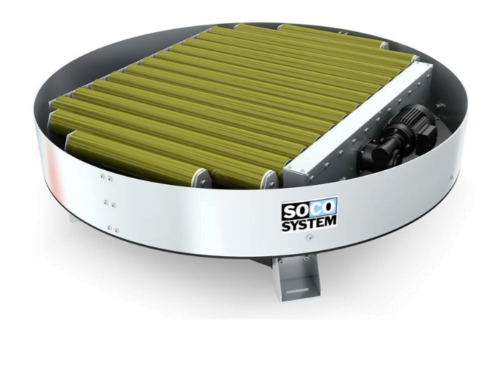

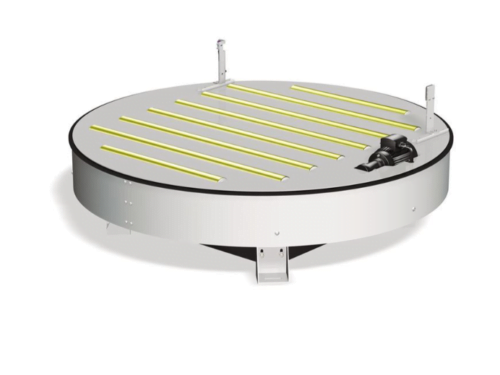

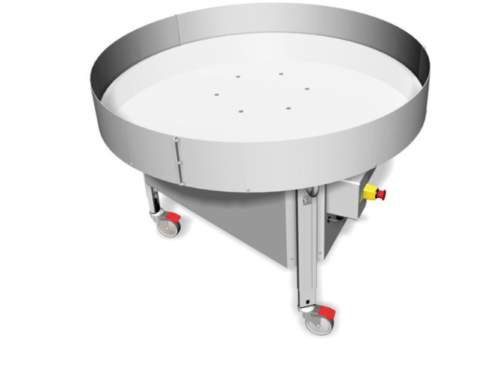

SOCO Roller conveyors with Ø 48 steel rollers

The rollers are smooth-running and suitable for heavy-duty situations where conditions are particularly demanding. A decline of 3-5% ensures unassisted item flow.

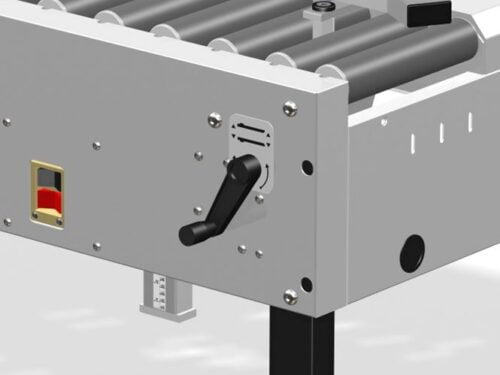

- The axle pitch can be changed without the use of tools.

- Silent system with very little friction.

- The frames of the conveyors are smooth with no sharp edges.