SOCO One man packaging system – Ergonomic version

Fill, seal and palletize from the same position with case erector. The operator slides the case into the case erector, where the bottom flaps are automatically folded and held firm during filling. When the case is full, the operator pushes it into tape sealer. The case will travel 180 degrees back to the operator, who can turn and palletize from the accumulation conveyor.

Fill, seal and palletize from the same position with case erector. The operator slides the case into the case erector, where the bottom flaps are automatically folded and held firm during filling. When the case is full, the operator pushes it into tape sealer. The case will travel 180 degrees back to the operator, who can turn and palletize from the accumulation conveyor.

- Assisted case erecting

- Flexible and easy to adjust

- Easy to maintain

- Easy tape thread

- Accumulation of taped cases

- Reduced operator movement

The package:

F-100 case former.

Case sealer type T-2000.

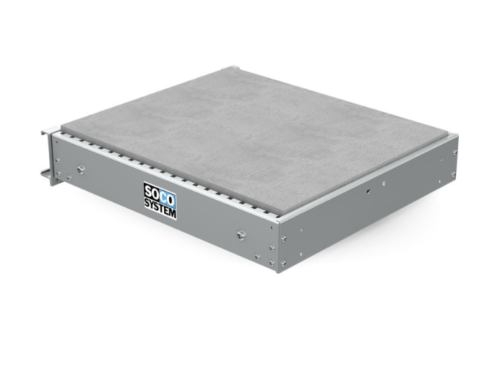

1 m outfeed conveyor.

180-degree flexi curve.

2 m accumulation conveyor with end stop.