Hugo Beck Robots & Handling Systems

EFFICIENT AND FLEXIBLE AUTOMATION SOLUTIONS

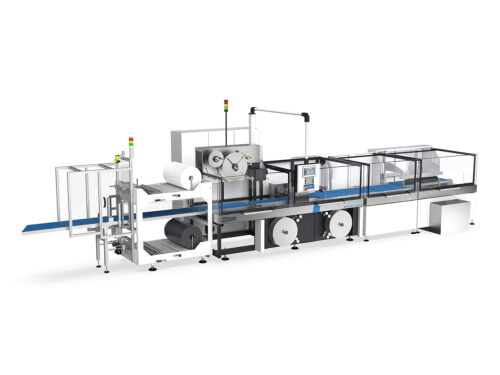

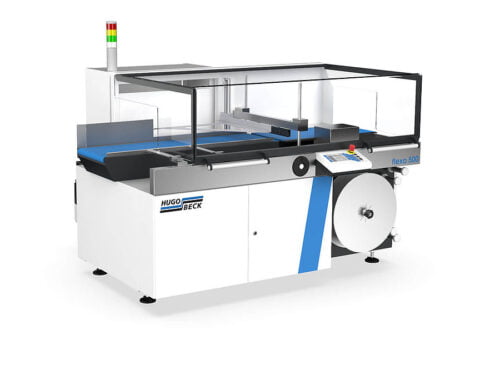

Hugo Beck can claim a decade-long development tradition when it comes to automation. They offer support with their expertise throughout the entire automation process, from project planning and manufacture right through to integration into complex packaging lines.

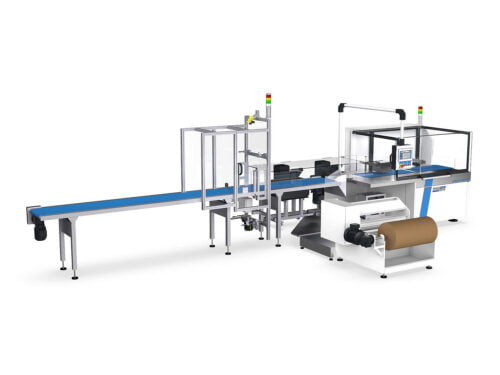

Handling systems such as portals, grouping solutions, stacking and counting devices, cross pusher to name but a few, are integrated reliably into the packaging solutions by our technicians.

Furthermore, various robots systems are used across many industries for the automated feeding of products, helping to for example grip, position, stack, group, stage products. From a parallel robot (also known as a spider robot) all the way through to a SCARA robot – anything is flexibly possible and delivered fully integrated according to each customer‘s needs.

Both robots and handling systems can all be purchased independently of Hugo Beck packaging machines.