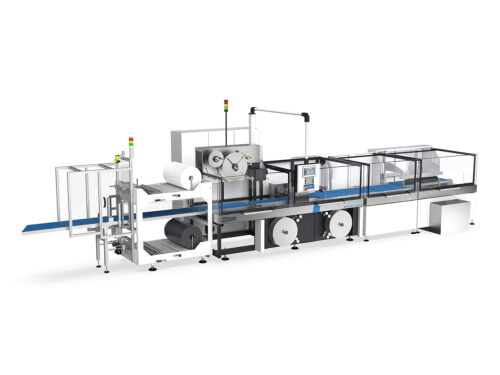

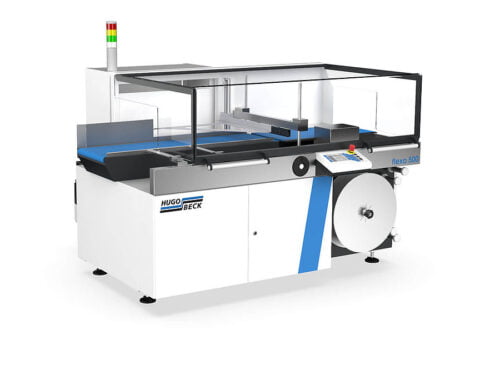

Hugo Beck Flexo 500/700 Push

Flexible pusher-machines for the packaging of bundles and difficult products.

The intermittent Form Fill and Seal machines flexo 500/700 Push are pusher-machines that wrap difficult products with ease, such as glass bottles in bundles or salt and pepper shakers.

They collect and group the products in order to subsequently push them into the film. In order to ensure that no products tilt over, our machines maintain physical contact with the articles to be packaged until they are safely in the bag.

The transversal sealing unit is designed as an intermittent version and processes a wide range of films and product dimensions. The packaging style features a bottom overlap.