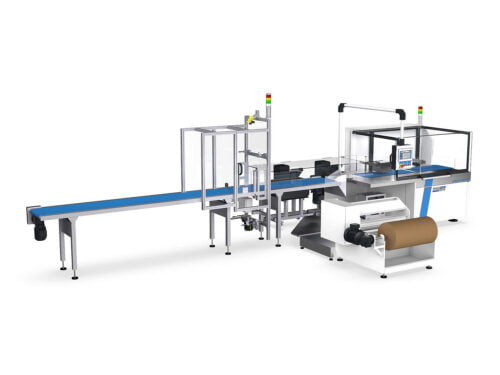

SOCO Pack ATS case erector – Tape

Erects the case and bottom seals it with tape – ready for filling. SOCO Pack ATS is a high speed, fully automatic case erector with integrated bottom tape sealer. The machine handles FEFCO 0201 cases as standard. As examples of extra functions, the case erector can be fitted with side flap spreader if cases are causing problems due to poor design or material quality. The machine is also prepared for cases with overlapping side flaps. The machine is also available partly in stainless steel.

Erects the case and bottom seals it with tape – ready for filling. SOCO Pack ATS is a high speed, fully automatic case erector with integrated bottom tape sealer. The machine handles FEFCO 0201 cases as standard. As examples of extra functions, the case erector can be fitted with side flap spreader if cases are causing problems due to poor design or material quality. The machine is also prepared for cases with overlapping side flaps. The machine is also available partly in stainless steel.

The SOCO SYSTEM case erector is the perfect start of the packaging line – improves ergonomics and increases productivity and automation. The pneumatic parts of the case erector are from Festo, and the PLC is Siemens.

- Compact machine.

- Easy installation.

- User-friendly software with numerous possibilities.

- Low noise level and low air consumption.